An electric wheel cover reinforcement plate for improving side collision safety performance

A technology of safety performance and side impact, applied in vehicle parts, upper structure sub-assembly, transportation and packaging, etc., can solve the problems of easy structure instability, large force component, poor crashworthiness, etc., and achieve good efficiency and stability , reasonable intrusion speed, and the effect of buffering impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

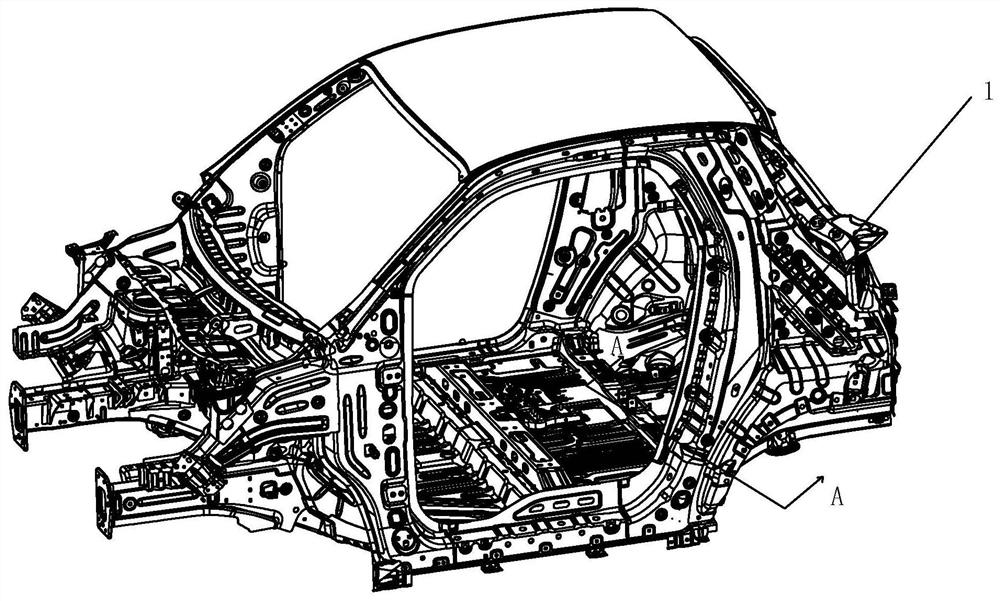

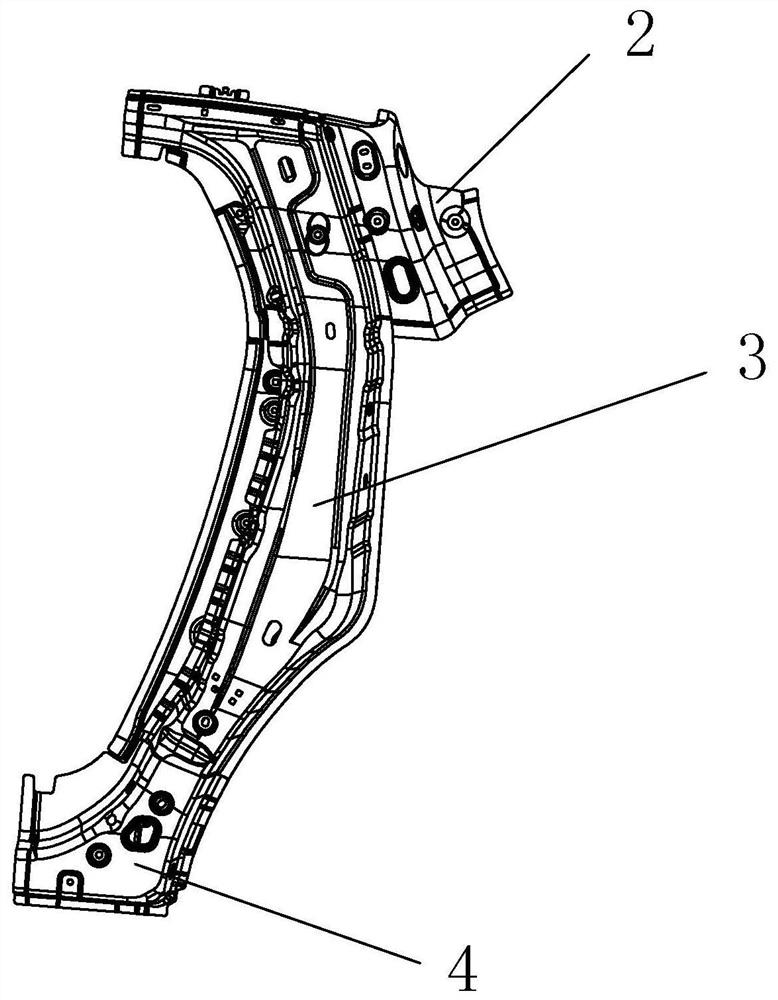

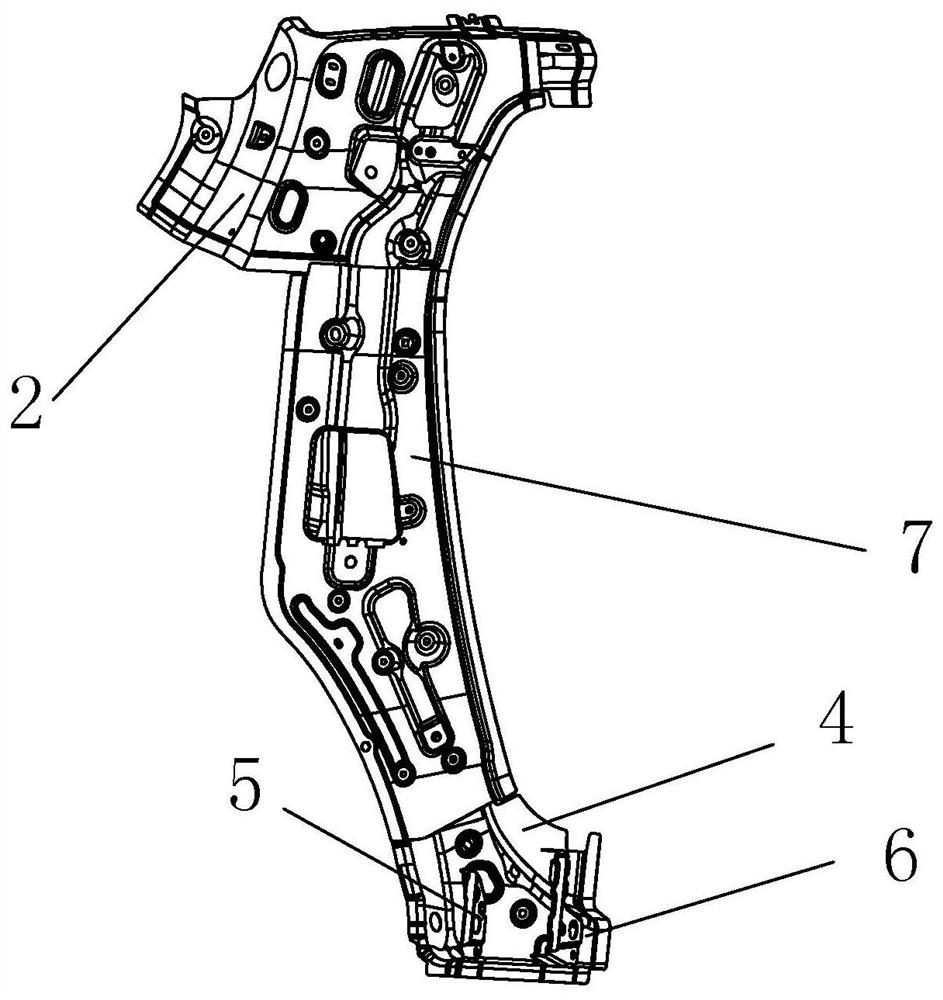

[0025] Such as figure 1 , 2 , 3, 4 and 9, an electric wheel house reinforcement plate for improving side collision safety performance includes a reinforcement plate body 1 installed on the vehicle body, the reinforcement plate body 1 includes a reinforcement plate top 3, and a transverse The section is in the shape of a few characters, the bottom of the upper part 3 of the reinforcing plate is provided with the lower part of the reinforcing plate 4, the side of the upper part of the reinforcing plate 3 close to the vehicle body is provided with the front part of the inner plate 7, and the top of the front part of the inner plate 7 is provided with the upper part of the inner plate 2, strengthening The lower section 4 of the panel is provided with a first threshold brace 5 and a second threshold brace 6 for connecting with the vehicle body, so that when the side of the vehicle body is collided, the stability of the structural design is higher, and the impact resistance is signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com