Deep trench excavation rapid forming machine and road culvert pipe refined construction method

A deep groove and fast technology, applied in the direction of road bottom, earth mover/shovel, construction, etc., can solve problems such as pipeline damage, collapse, blockage, low efficiency, and difficulty in ensuring the consistency of groove depth. , to achieve the effect of pipe laying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

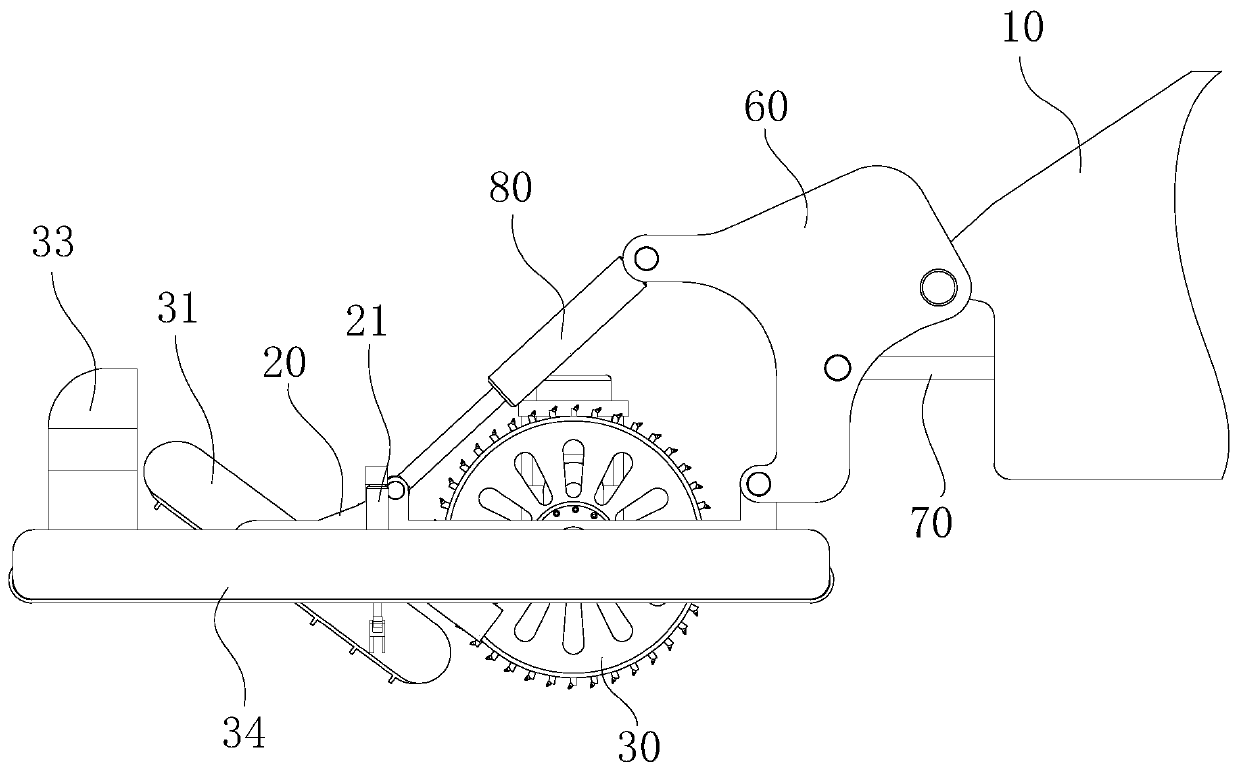

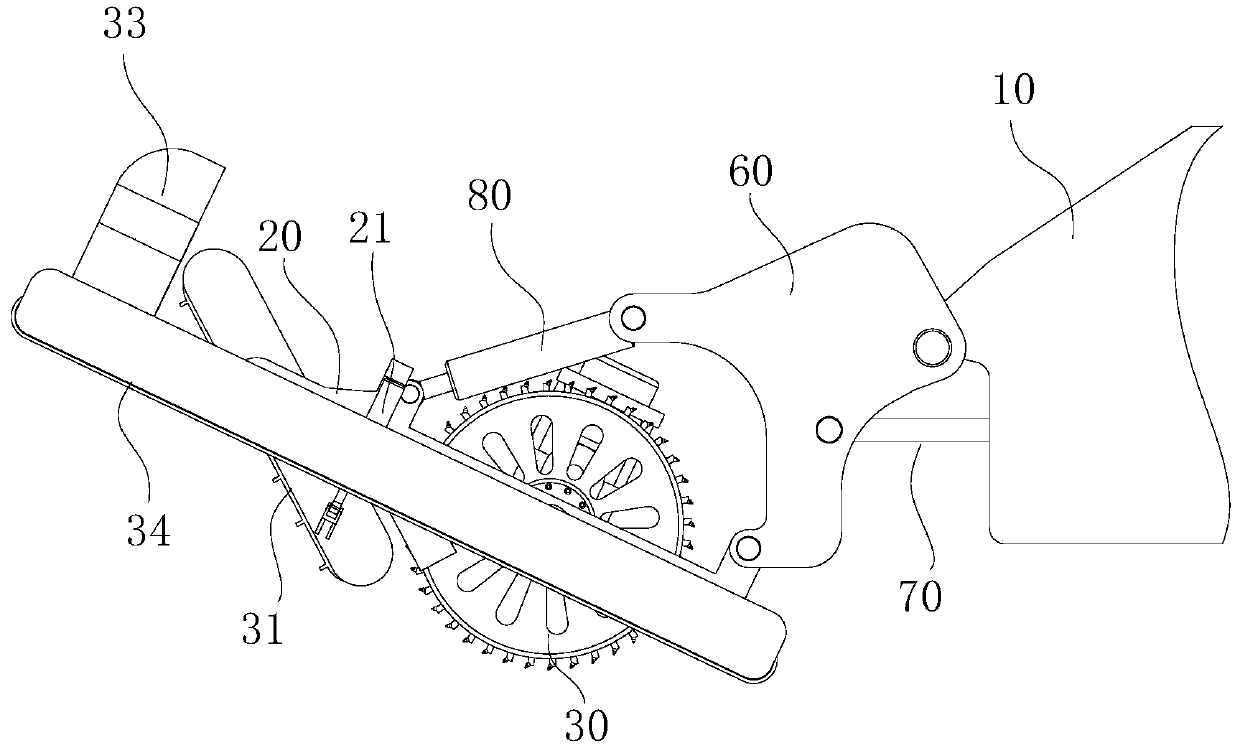

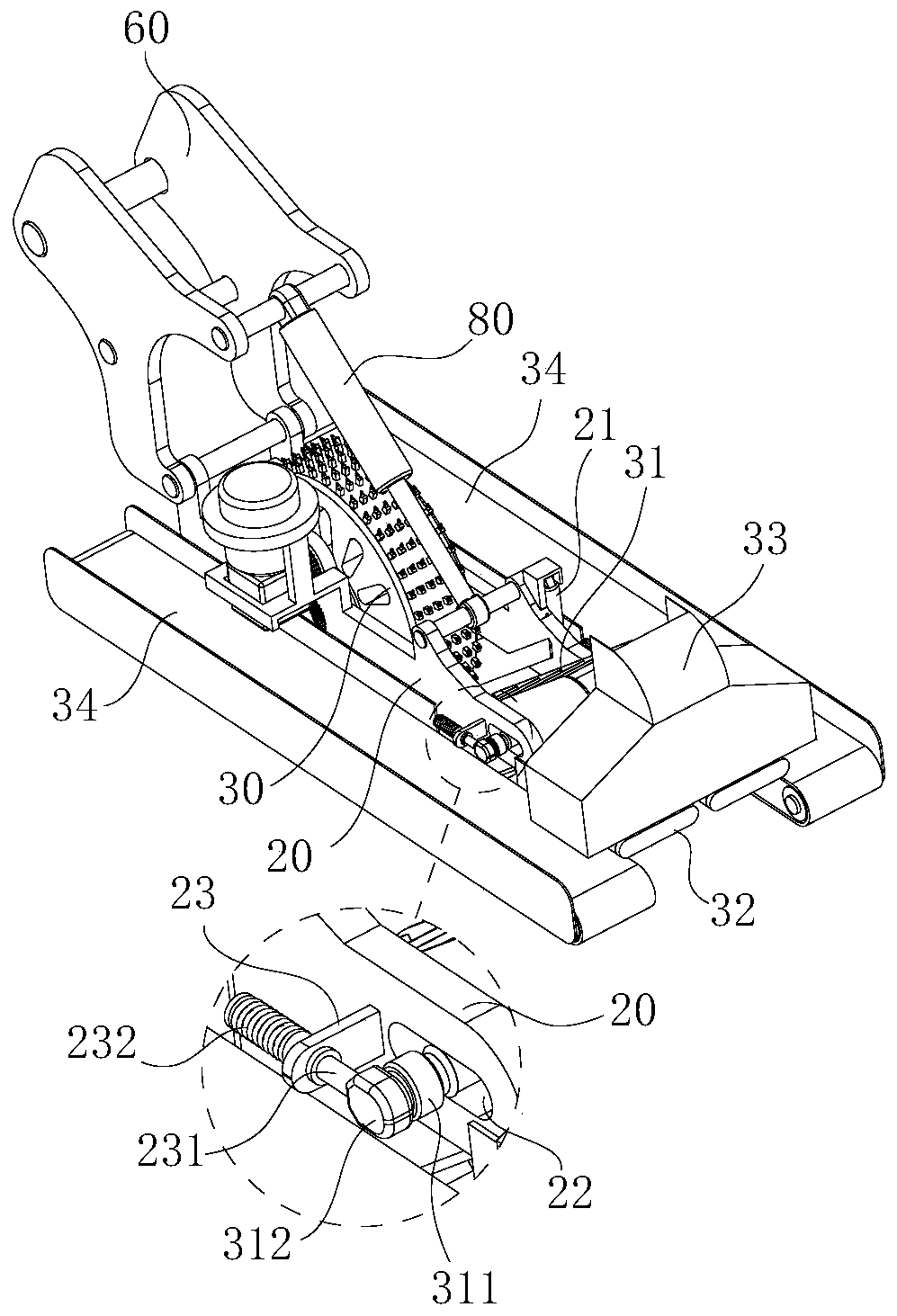

[0036] refer to Figure 1 to Figure 10 , the structural features of this deep trench excavation rapid prototyping machine are described in detail as follows:

[0037] The rapid prototyping machine for deep trench excavation includes a bracket arm 20 arranged on the mobile vehicle 10, and a milling wheel 30 is rotatably arranged on the bracket arm 20, and the milling wheel 30 has a wheel core and is connected with a driving mechanism. The driving mechanism drives the milling wheel 30 to rotate, and the side of the mobile vehicle 10 is also provided with a pipeline feeding mechanism 40, and the discharge port of the pipeline feeding mechanism 40 is provided with a pipeline laying mechanism 50, and the pipeline laying mechanism 50 the exit is horizontal and directed towards the rear end of the mobile vehicle 10;

[0038] combine figure 1 and figure 2 As shown, the mobile vehicle 10 supports the milling wheel 30 to move along the length direction of the base surface, and start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com