Electrode for potential detection of electromagnetic flowmeter

An electromagnetic flowmeter and potential detection technology, which is applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, liquid level indicator for physical variable measurement, etc., can solve the peeling of precious metal materials and corrosion of measuring tubes , Measuring tube to apply impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

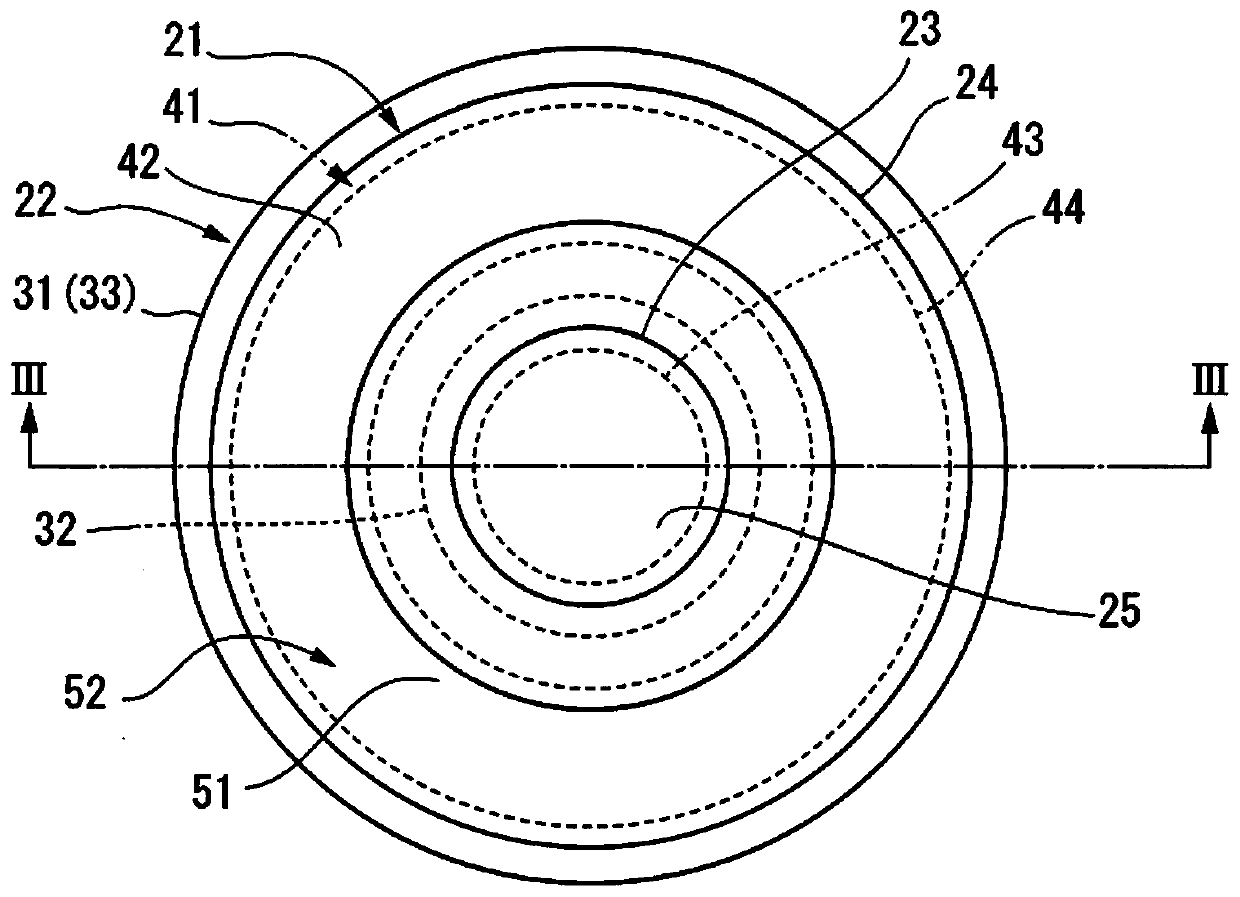

[0034] Below, refer to Figure 1 ~ Figure 5 An embodiment of the electrode for potential detection of the electromagnetic flowmeter according to the present invention will be described in detail.

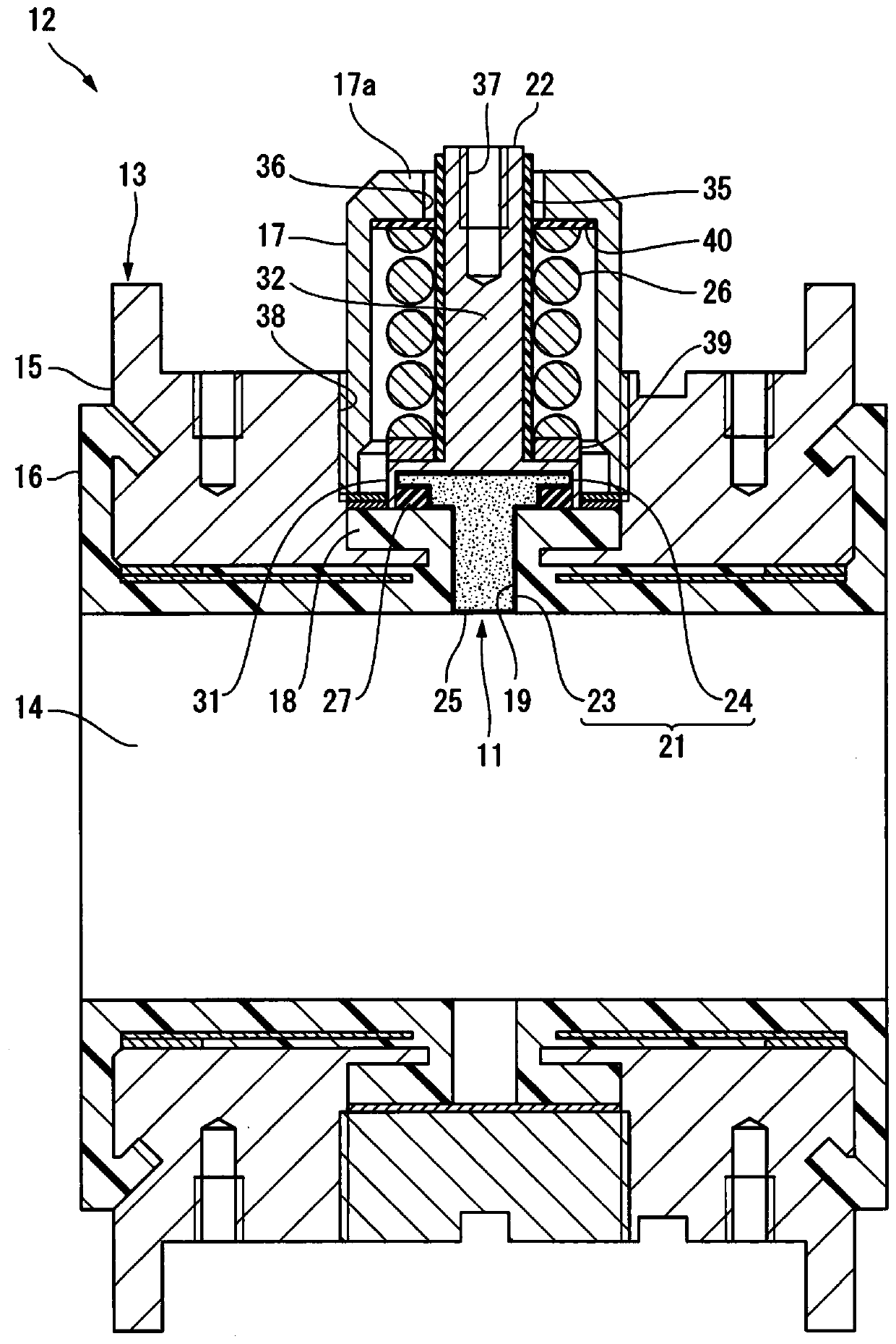

[0035] figure 1 The illustrated electrode 11 for potential detection (hereinafter, simply referred to as electrode 11) is attached to the measuring tube 13 of the electromagnetic flowmeter 12 from the outside of the fluid passage 14.

[0036] The measurement tube 13 includes a main body 15, an inner liner 16 provided on the inner surface of the main body 15, a bottomed cylindrical electrode cap 17 that accommodates the electrode 11, and the like. The electrode mounting seat 18 is integrally provided to the inner liner 16. The electrode mounting seat 18 is provided with an electrode insertion hole 19 for inserting the electrode 11.

[0037] The electrode 11 of the present embodiment includes a main body 21 inserted into the electrode insertion hole 19 of the inner liner 16 and a terminal ...

no. 2 Embodiment approach

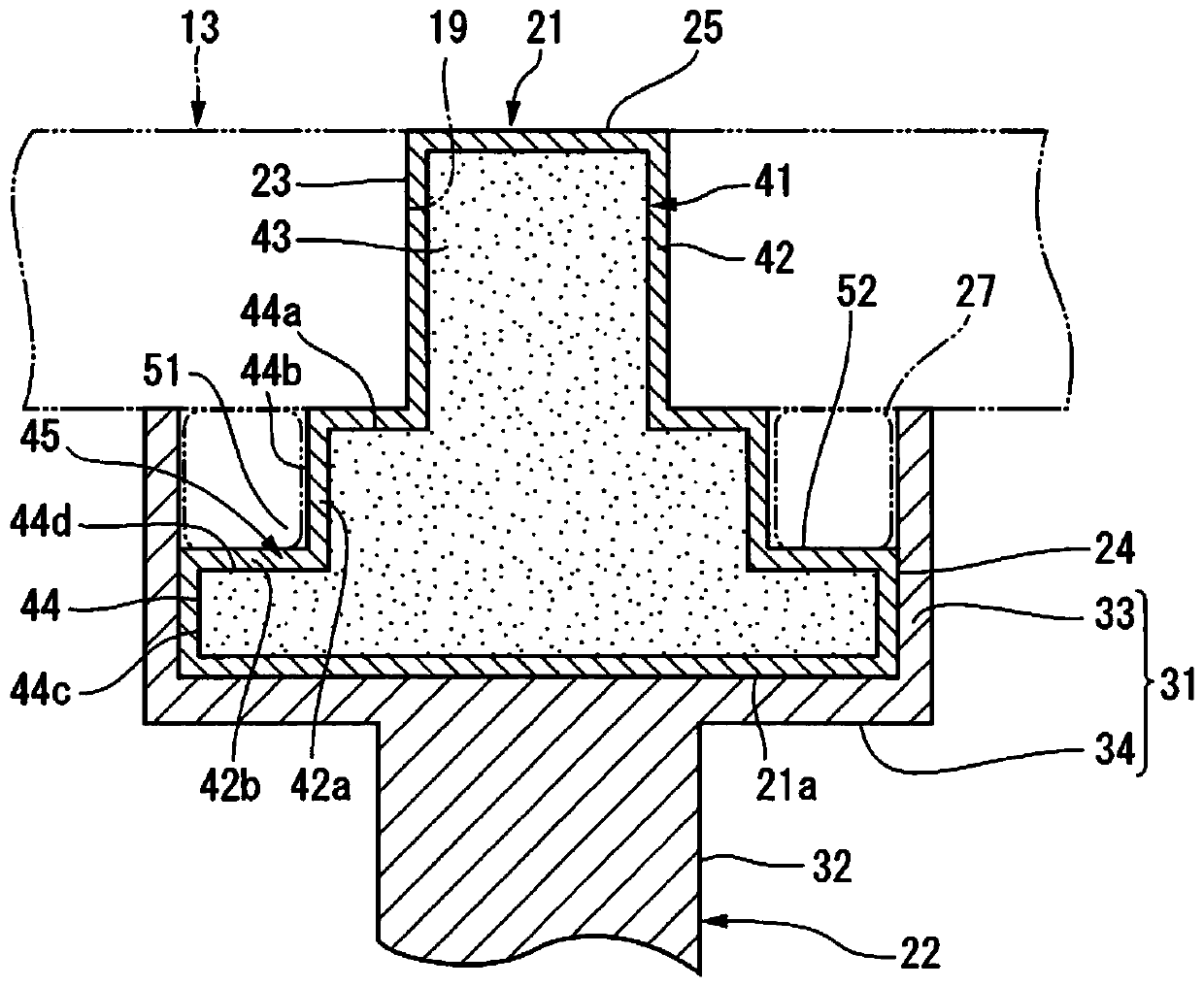

[0053] The electrode for potential detection of the present invention can be as Image 6 as well as Figure 7 Structure as shown. in Image 6 as well as Figure 7 In, for and Figure 1 ~ Figure 5 The same or equivalent members of the described members are denoted by the same reference numerals, and detailed descriptions are appropriately omitted.

[0054] Image 6 as well as Figure 7 The shown potential detection electrode 61 is composed of a main body 21 and a terminal 22. The main body 21 has a large-diameter disk-shaped portion 24 without a step on the outer periphery. The terminal 22 is provided with the main body 21 The outer peripheral surface of the fitting cylinder 33. The large-diameter portion 24 of the main body portion 21 is formed such that the outer diameter is constant over the entire area in the axial direction.

[0055] The cylindrical body 33 of this embodiment has a first inner peripheral surface 33b extending in the axial direction from the inner peripheral ed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap