Flat net making machine

A net machine and flat net technology, applied in the field of laser net making equipment, can solve problems such as beam bending, affecting net making efficiency, and lasers running unsmoothly, so as to achieve the effect of improving efficiency, improving exposure quality, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

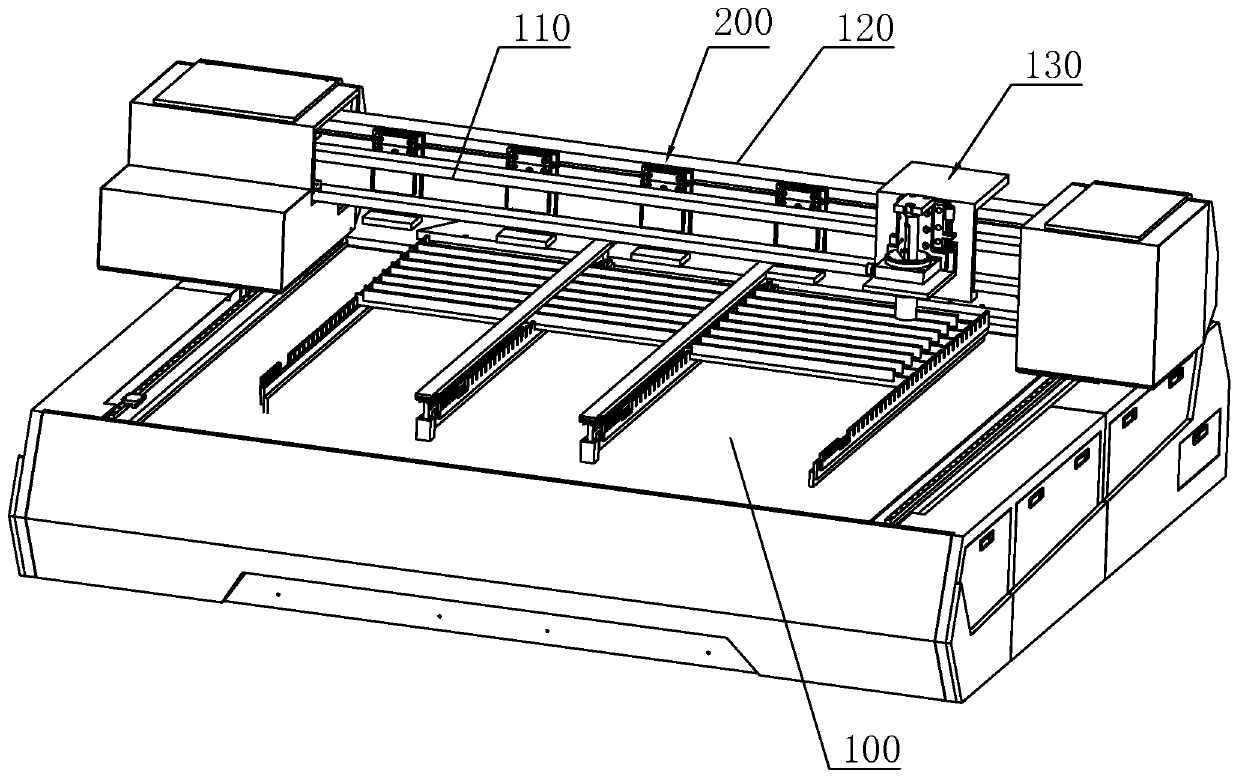

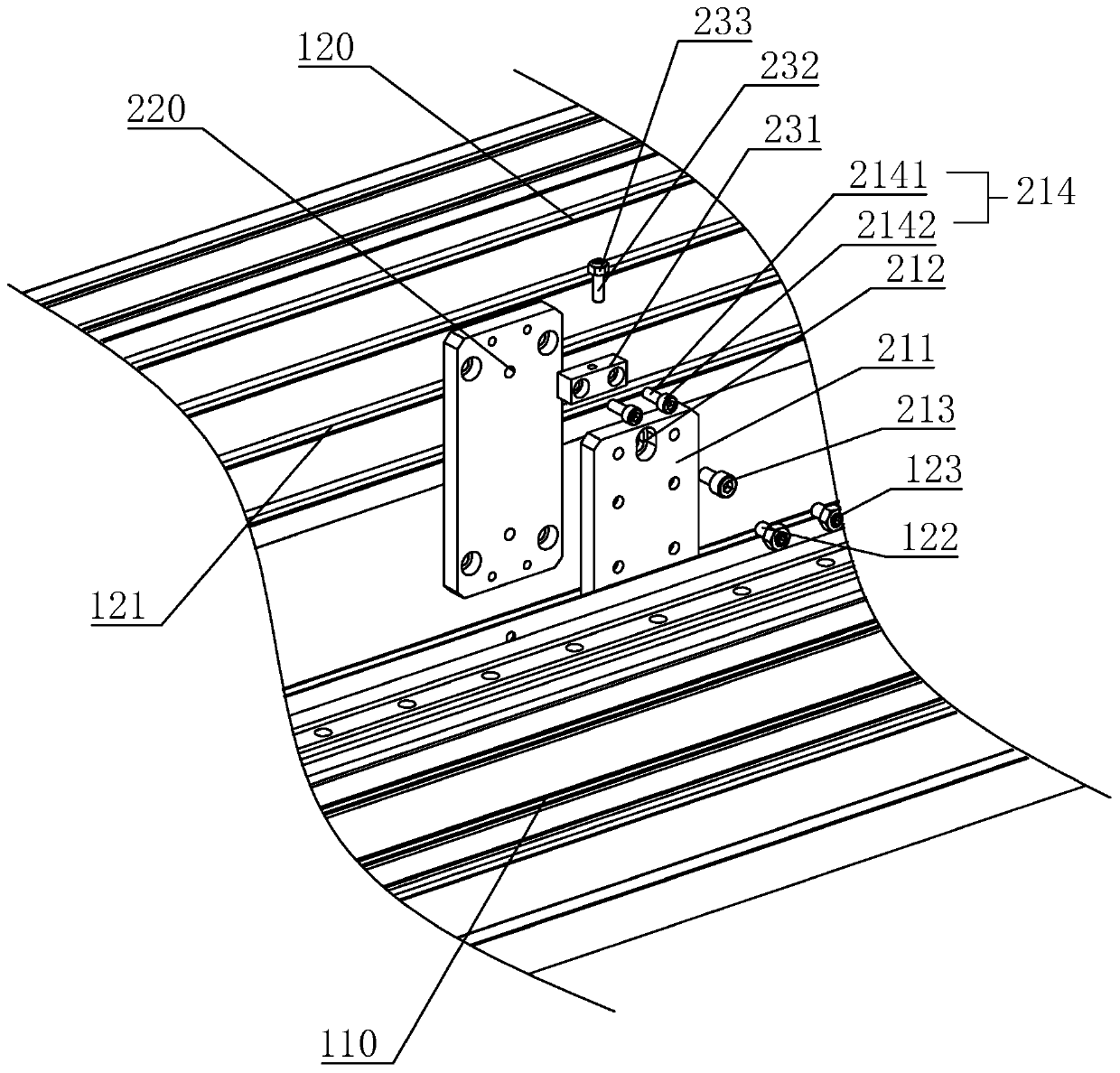

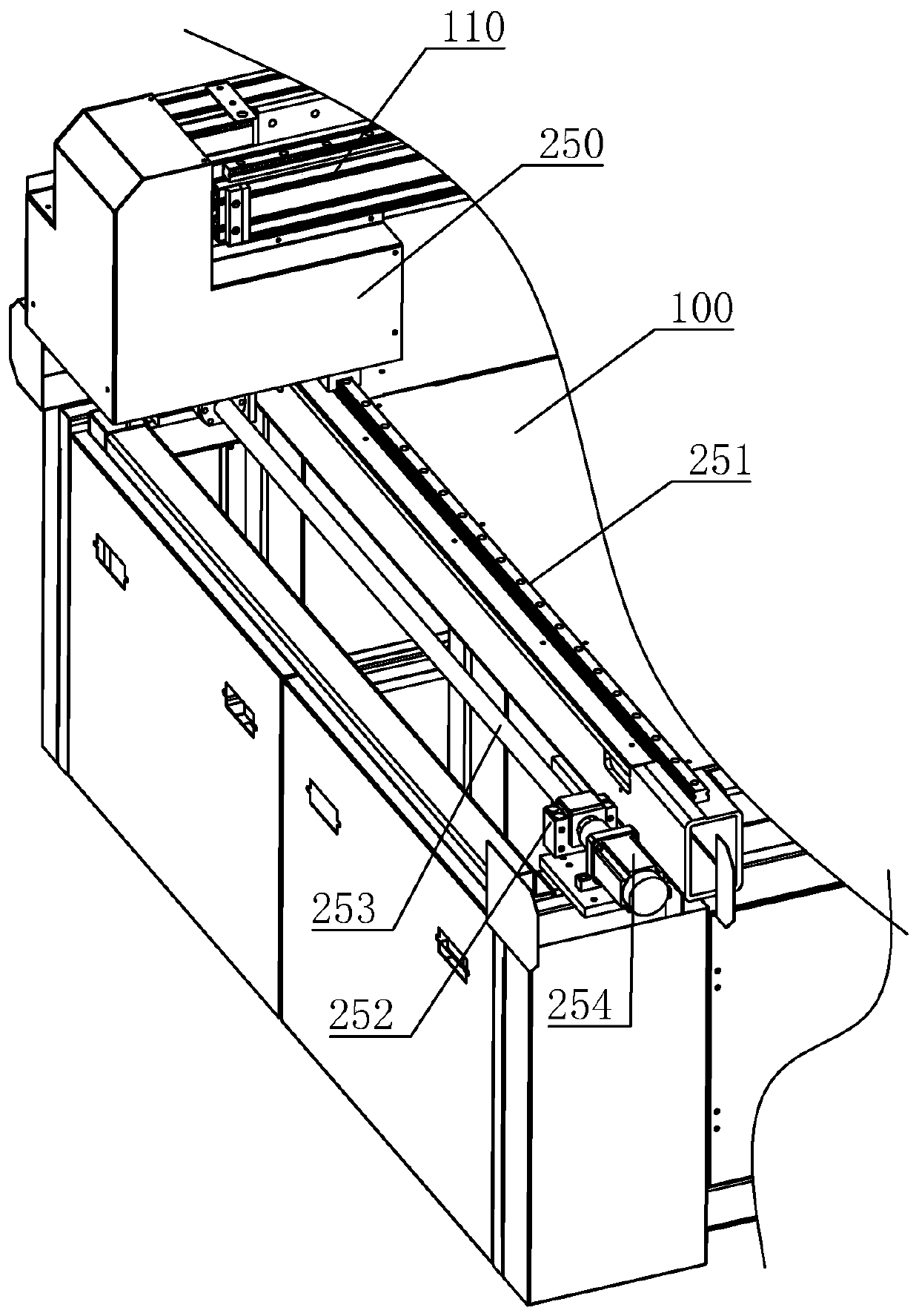

[0032] A kind of flat net making machine, refer to figure 1 and figure 2 , including a workbench 100 and a crossbeam slidably arranged on the workbench 100, the crossbeam includes a front beam 110 and a rear beam 120 arranged in parallel, the front beam 110 is slidably connected with a machine head 130 emitting laser, and the rear beam 120 is provided with at least An adjustment device 200 for adjusting the straightness of the front beam 110 . Multiple are used in this embodiment.

[0033] The adjusting device 200 includes a first panel 220 connected to the rear beam 120, a force application mechanism that is slidably connected to the first panel 220, and a driving mechanism that is arranged on the first panel 220 and drives the force application mechanism. 110 abutments. The force applying mechanism includes a second panel 211, the upper and low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap