Test method for stability of POE packaging adhesive film for solar cells

A technology for solar cells and encapsulation films, used in semiconductor/solid-state device testing/measurement, etc., can solve problems such as cell cracks, loose junction boxes, increased risks, etc., and achieve simple test methods, improved reliability, and reliable results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for testing the stability of a solar cell POE packaging adhesive film, comprising the steps of:

[0038] (1) Take 100×100mm samples of the 3M 8110 POE film, and after lamination on the laminator, cut them according to 40mm×5.5mm to obtain test samples, and measure the tensile strength of the package film POE through the pre-test. The ultimate load that can be reached at 100°C is 0.01MPa, and the test tensile load value of the selected step (3) is 0.005MPa; the length of the test sample is recorded as L 1 ;

[0039] (2) Use the clamps of the dynamic mechanical thermal analyzer to fix the two ends of the strip-shaped encapsulation film, flatten it and place it in a closed environment, and perform the pollution level test according to the test sequence of the IEC61730-2 photovoltaic module safety certification test standard, specifically as follows:

[0040]①Dry cooling at -40°C for 48 hours;

[0041] ②In an environment with a temperature of 105°C and a humidit...

Embodiment 2

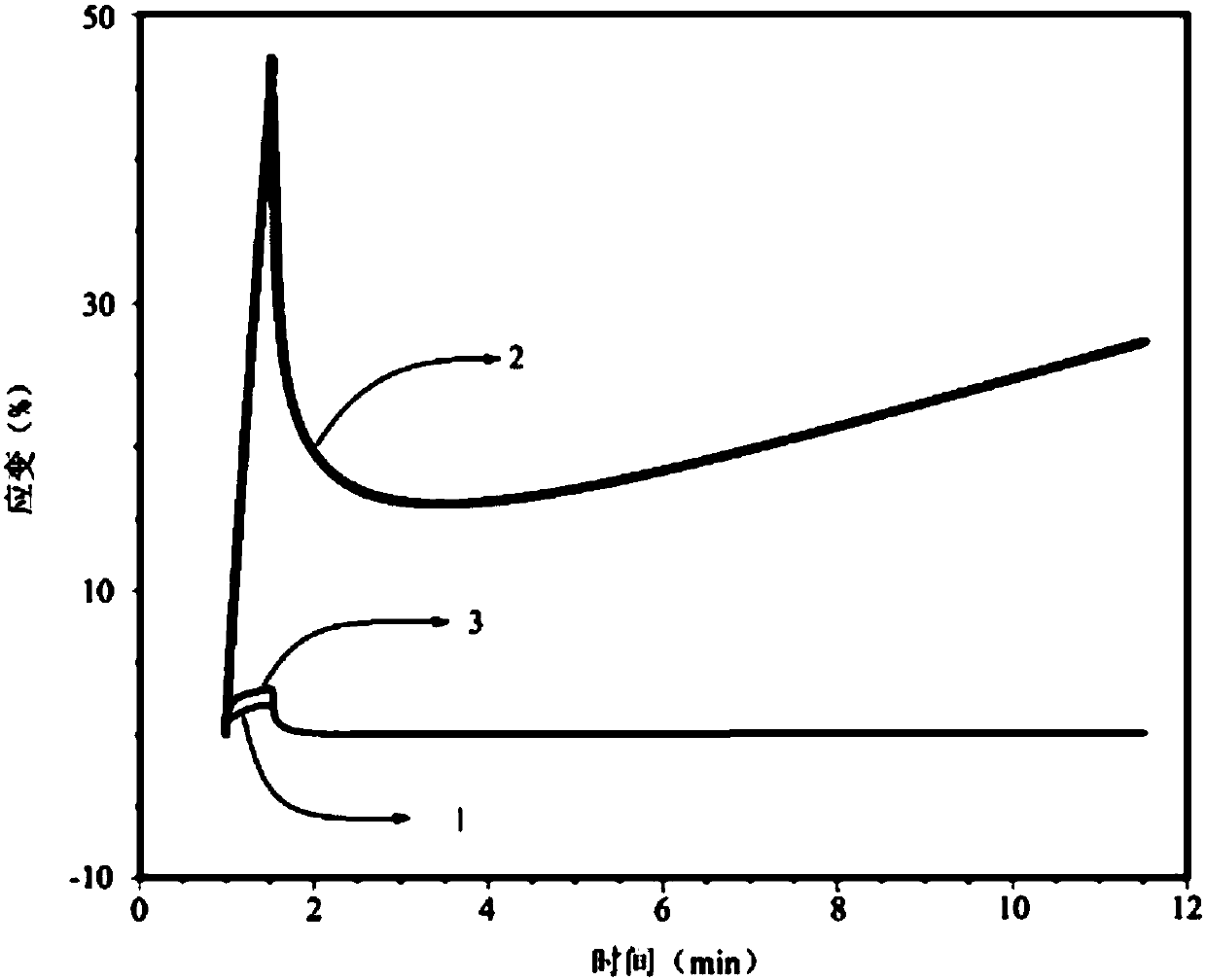

[0048] The difference from Example 1 is that the model of the POE film is Dow Enlight, its ultimate load is tested at 0.02MPa, and its tensile load is set at 0.006MPa. figure 1 Curve 2 is the strain curve of Example 1 sample. After calculation, |L 2 -L 1 | / L 1 41.6%, greater than 1%, it is judged that when the POE film is used outdoors after solar cell packaging, the stability is unqualified. figure 1 Curve 2 is the strain curve of Example 2 sample.

Embodiment 3

[0050] The difference from Example 1 is that the model of the POE film is Cybrid T22, its ultimate load is tested to be 0.014MPa, and its tensile load is set to be 0.0112MPa. figure 1 Curve 2 is the strain curve of Example 1 sample. After calculation, |L 2 -L 1 | / L 1 If it is 0.16%, less than 1%, it is judged that the stability of the POE adhesive film is qualified when it is used outdoors after solar cell packaging. figure 1 The curve 3 is the strain curve of the sample of Example 3.

[0051] The results of the peak strain and the deformation rate after recovery of the three kinds of POE films in Examples 1 to 3 are shown in Table 1:

[0052] Table 1

[0053] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com