Full-automatic tying machine

A strapping machine, fully automatic technology, applied in the parts, packaging and other directions of strapping machinery, can solve problems such as unstable placement, product damage, product easily placed crooked or tilted, etc., to improve the strapping effect, high degree of automation, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

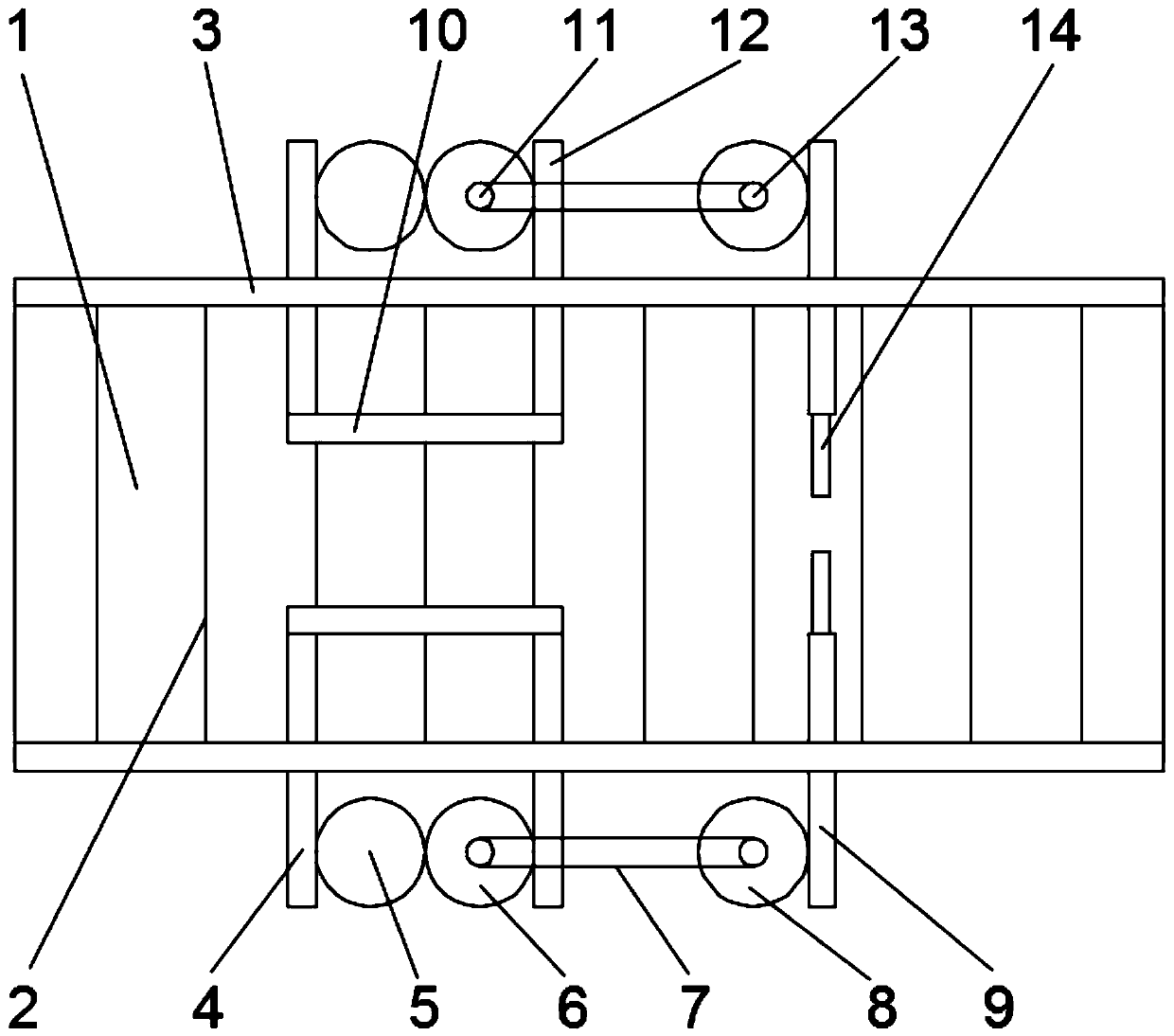

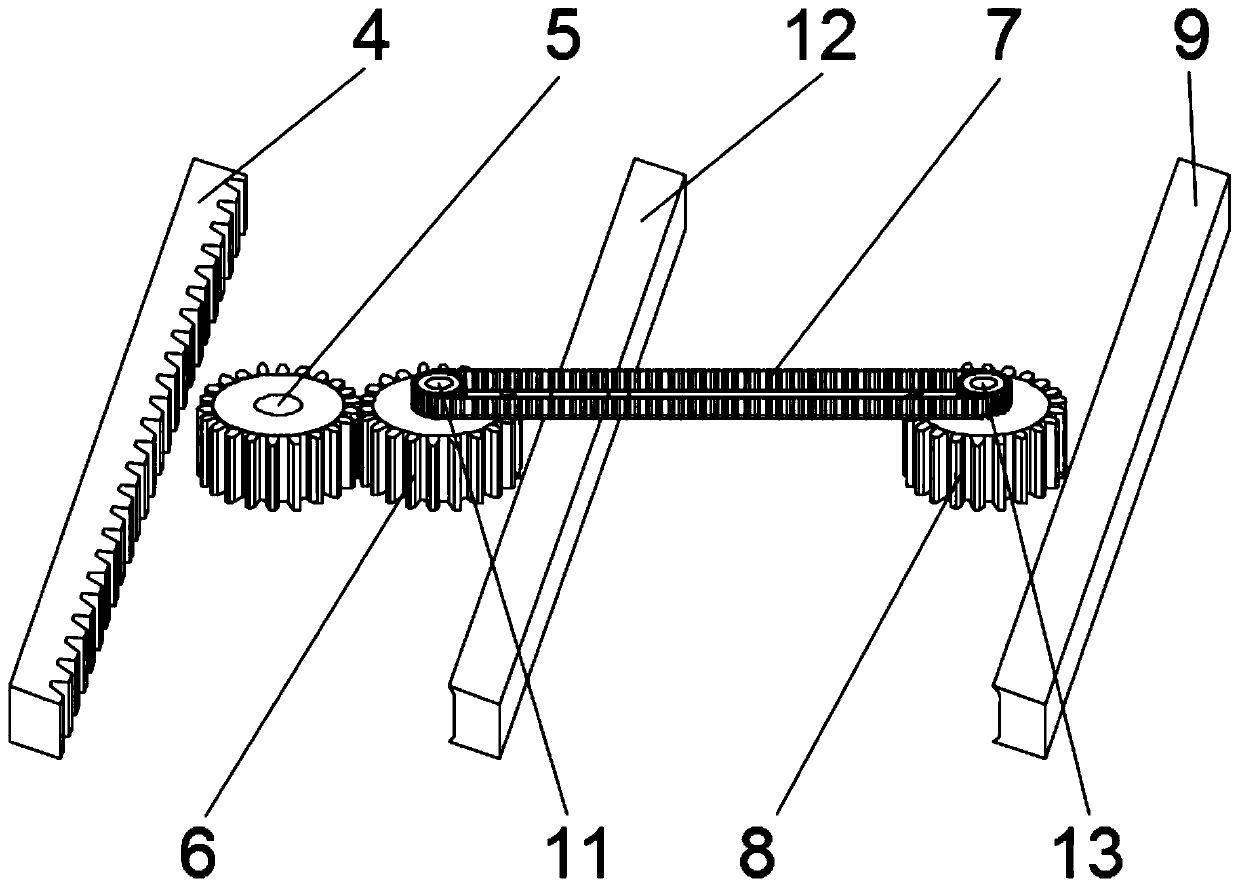

[0024] Such as figure 1 , 2 The full-automatic strapping machine shown includes a strapping mechanism and a transmission mechanism 1. The conveyor mechanism 1 includes a conveyor frame and a conveyor belt 2. The products to be bundled are placed on the conveyor belt 2 and sent to the strapping mechanism through the conveyor belt 2 for strapping. After the strapping is completed, the The bundling of the next product is sent out by the conveyor belt 2, and the existing structure is adopted, and its structure and connection mode are well known to those skilled in the art, and will not be described in detail; A one-by-one correction mechanism is installed, and the products are corrected one by one by installing the one-by-one correction mechanism on the fixed frame 3, which solves the problem of product accumulation and blockage and prevents irregularities when the current strapping machine is used, so that the products to be bundled can be corrected one by one and carried out. B...

Embodiment 2

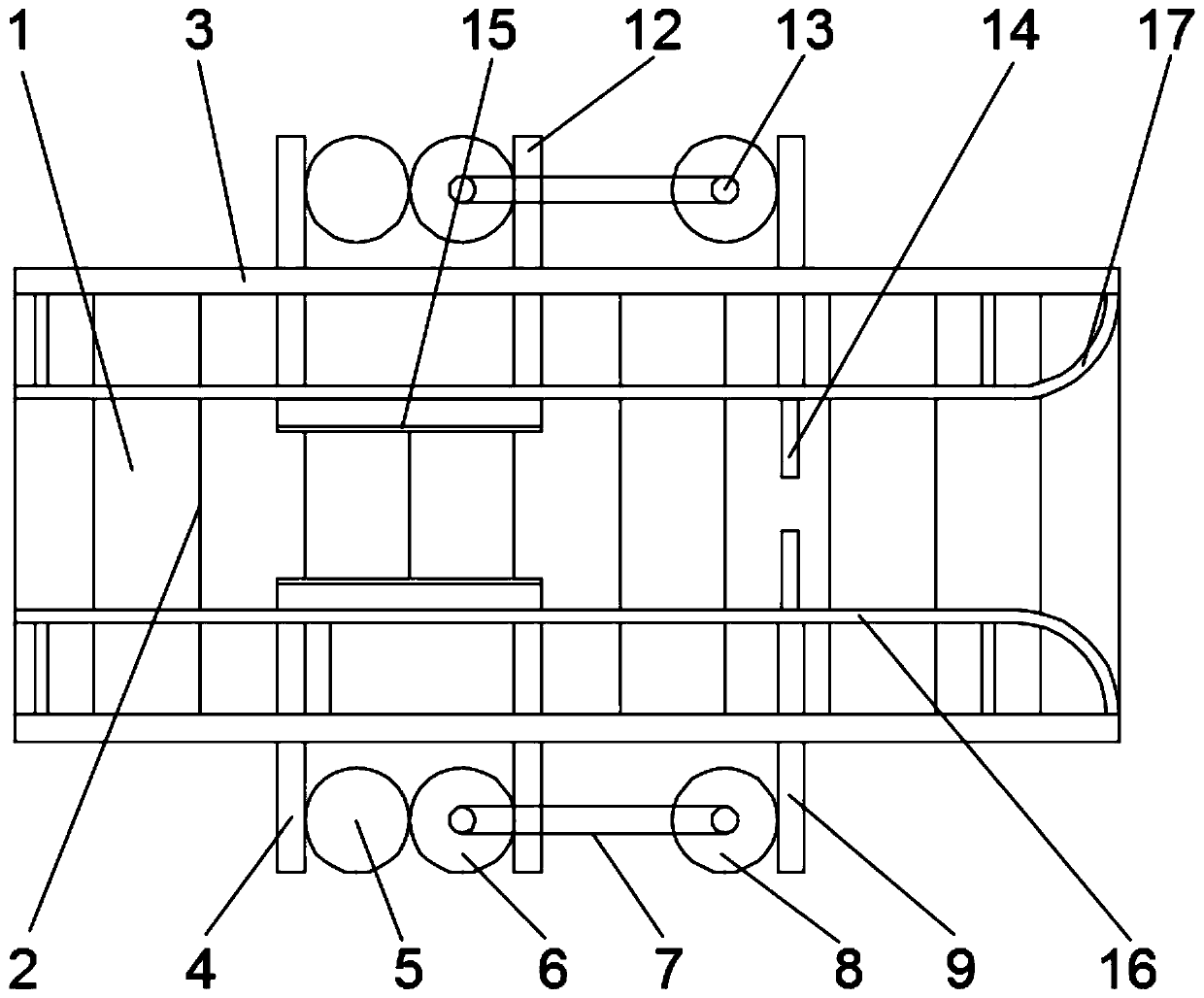

[0027] This embodiment is further optimized on the basis of the embodiment, such as image 3 As shown, the surface of the push plate 10 is fixedly equipped with an anti-skid pad 15, which is soft rubber or soft plastic, and is fixed on the surface of the push plate 10 by gluing or thermoplastic to protect the product to be bundled and prevent the product from being damaged during correction. .

[0028] The inside of the fixed frame 3 is also equipped with a fence 16. The fence 16 is fixedly connected with the fixed frame 3 through a support rod. By setting the fence 16 to constrain the product, it is convenient to form a correction mechanism for correction.

[0029] The fence 16 is fixedly installed with an arc-shaped plate 17 connected thereto, and the arc-shaped plate 17 is arranged on the rear side of the forward direction of the conveyor belt 2, which is convenient for drainage, so that products placed at will can smoothly enter the fence 16, reducing the accuracy of preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com