Wave-absorbing camouflage cloth and preparation method thereof

A technology of wave absorbing agent and non-woven fabric, applied in the field of wave absorbing materials, can solve the problems of surface structure damage and wave absorbing performance of camouflage cloth, so as to enhance the wave absorbing performance and safety performance, strengthen the wave absorbing performance, and strengthen the combination effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention provides an absorbent camouflage cloth, which includes: 13.6% nonwoven fabric, 6.8% absorbent, 6.6% adhesive, and anhydrous ethanol; Calculation includes: 14.7% hollow silicon carbide spherical nanoparticles, 7.6% oxide oxide, 1.8% multi-walled carbon nanotubes, 6.7% polyacrylonitrile, 5.7% silver nitrate, and the rest is polylactic acid; adhesive according to weight Percentage calculations include: 0.9% nanoculin, 1.7% high / 5.6% reactive polyamide resin, 29.5% hollow microbeads, and the rest are epoxy resins;

[0027] A method of preparing an absorbing camouflage cloth, and the specific preparation steps are as follows:

[0028]Step 1: In accordance with the weight of the weight, the nonwoven fabric, the hollow silicon carbide spherical nanoparticles, oxide oxide, multi-wall carbon nanotubes, polyacrylonitrile, silver nitric acid, polylactic acid, and adhesive Cellulose, potassium uretalate, reactive polyamide resin, hollow microbead, epoxy resin an...

Embodiment 2

[0036] Unlike Example 1, according to the weight percentage of nonwoven fabric, 7.8% absorbent, 7.6% adhesive, and the rest is anhydrous ethanol; the absorbent is calculated according to weight percentage: 15.5% of hollow silicon carbide spherical nanoparticles, 8.6% oxide oxide, 2.4% multi-walled carbon nanotubes, 7.5% polyacrylonitrile, 6.5% silver nitrate, the rest is polylactic acid; the adhesive is calculated according to the weight percentage : 1.5% of nanochemical, 2.5% potassium highly iodine, 6.6% reactive polyamide resin, 31.5% hollow microbeads, and the rest are epoxy resins.

Embodiment 3

[0038] Unlike Example 1-2, it is calculated according to the weight percentage of nonwoven fabric, 7.3% absorbent, 7.1% adhesive, and the rest is anhydrous ethanol; the absorbing agent is percentage Calculation includes: 15.1% of hollow silicon carbide spherical nanoparticles, 8.1% gossipide, 2.1% multi-walled carbon nanotubes, 7.1% polyacrylonitrile, 6.1% silver nitrate, and the rest is polylactic acid; adhesive according to weight The percentage calculation includes: 1.2% nanoculin, 2.1% potassium highly iodine, 6.1% reactive polyamide resin, 30.5% hollow beads, and the rest is an epoxy resin.

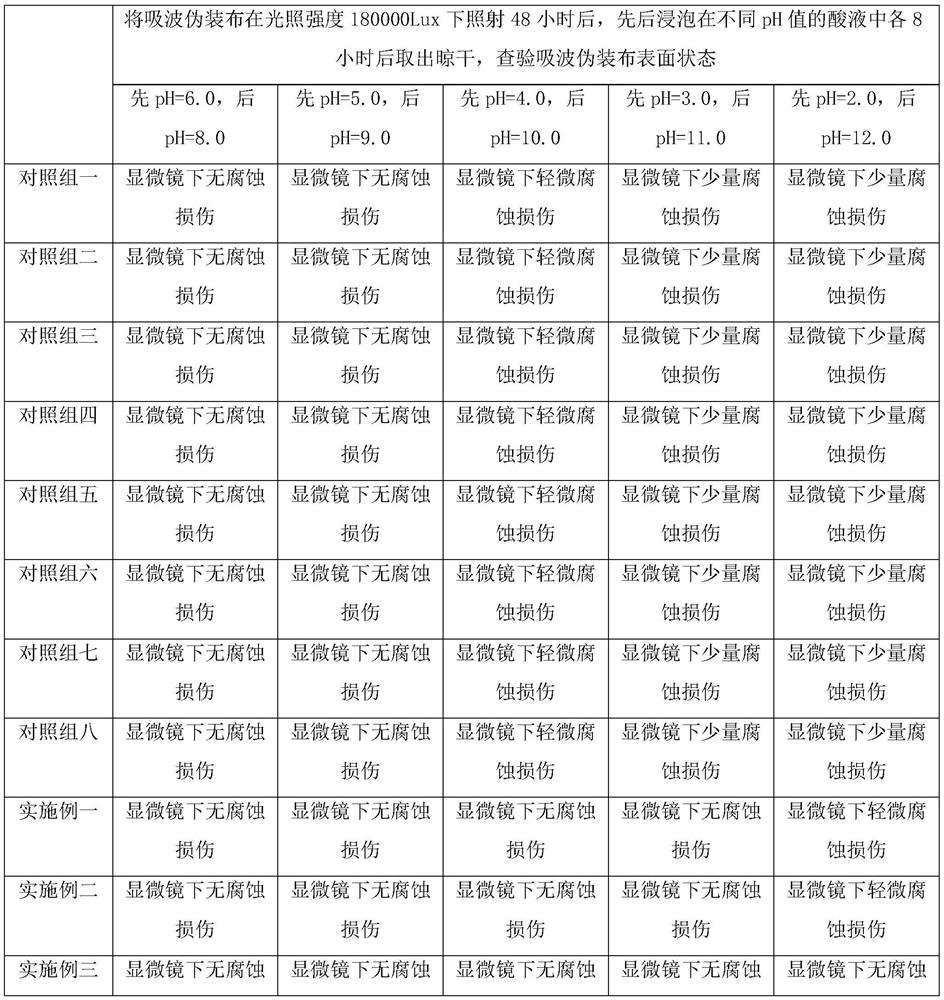

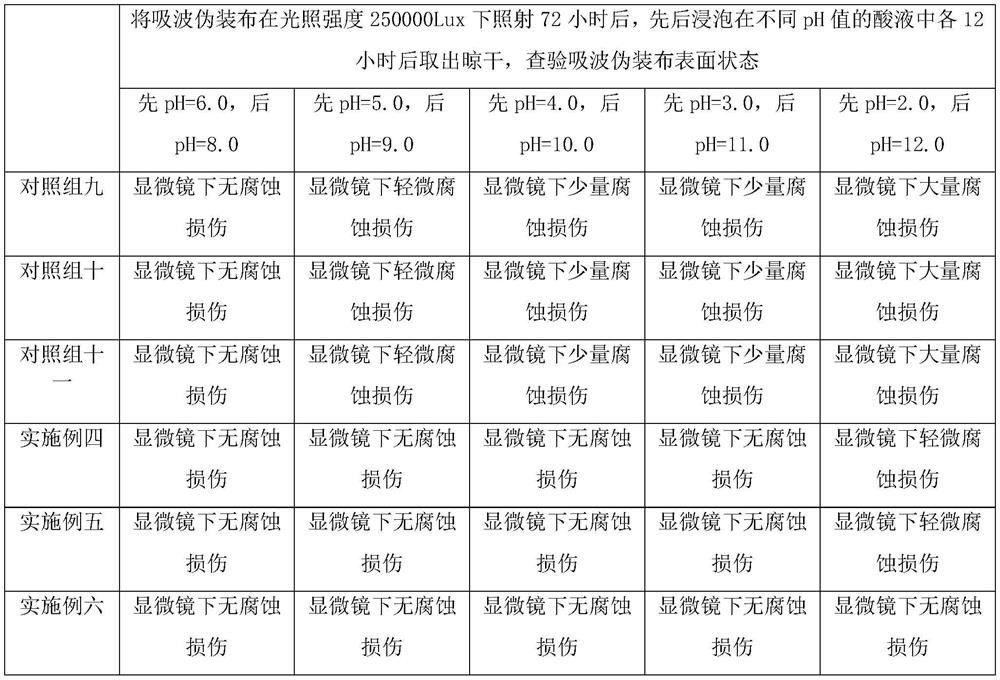

[0039] The absorbing camouflage cloth from the above-described Examples 1-3 and the control group 1, the absorbing camouflage cloth of the control group, the absorbent camouflage cloth, the control group three, respectively, the absorbing wave of the control group The absorbing camouflage cloth of the induced group 5, the absorbing camouflage cloth of the control group 6, and the absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com