Orientation preserving rotary transfer manipulator

A technology of manipulator and rotating shaft, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of single material transfer, inability to take into account the high-speed transfer of various layout combinations, linkage system design, and no systematic combination, etc., to improve stability. The effect of reducing the proportion of linkage space and combining richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

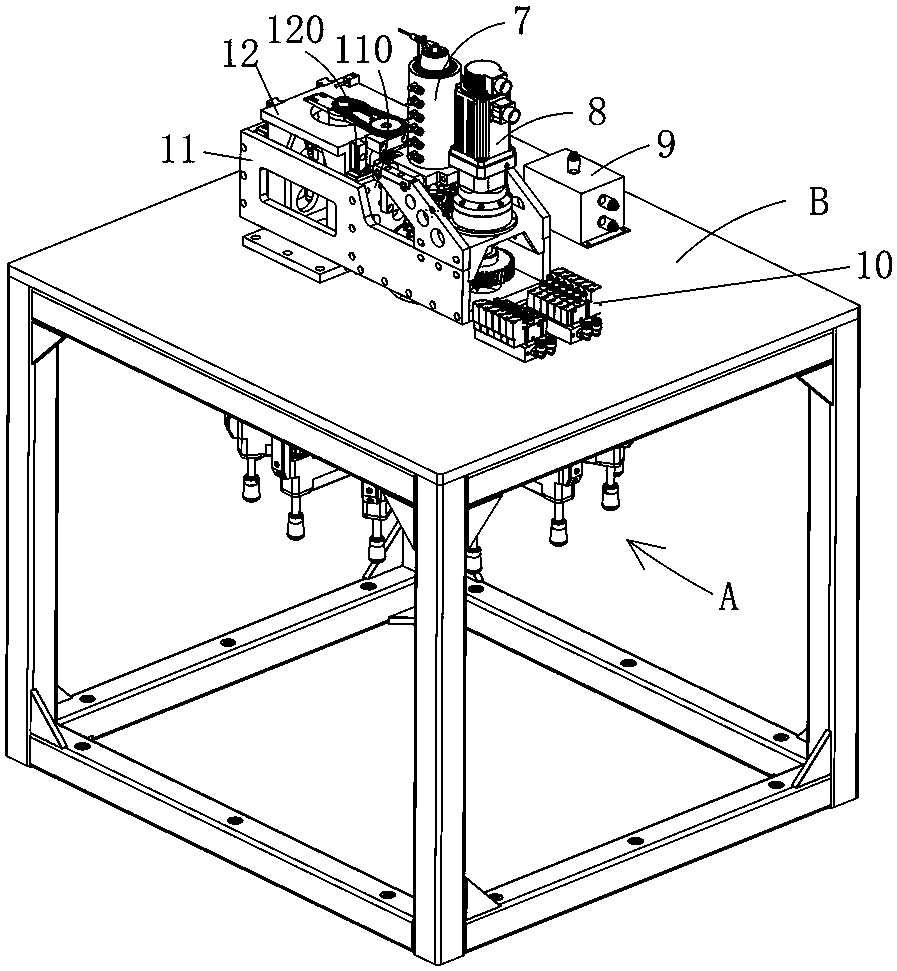

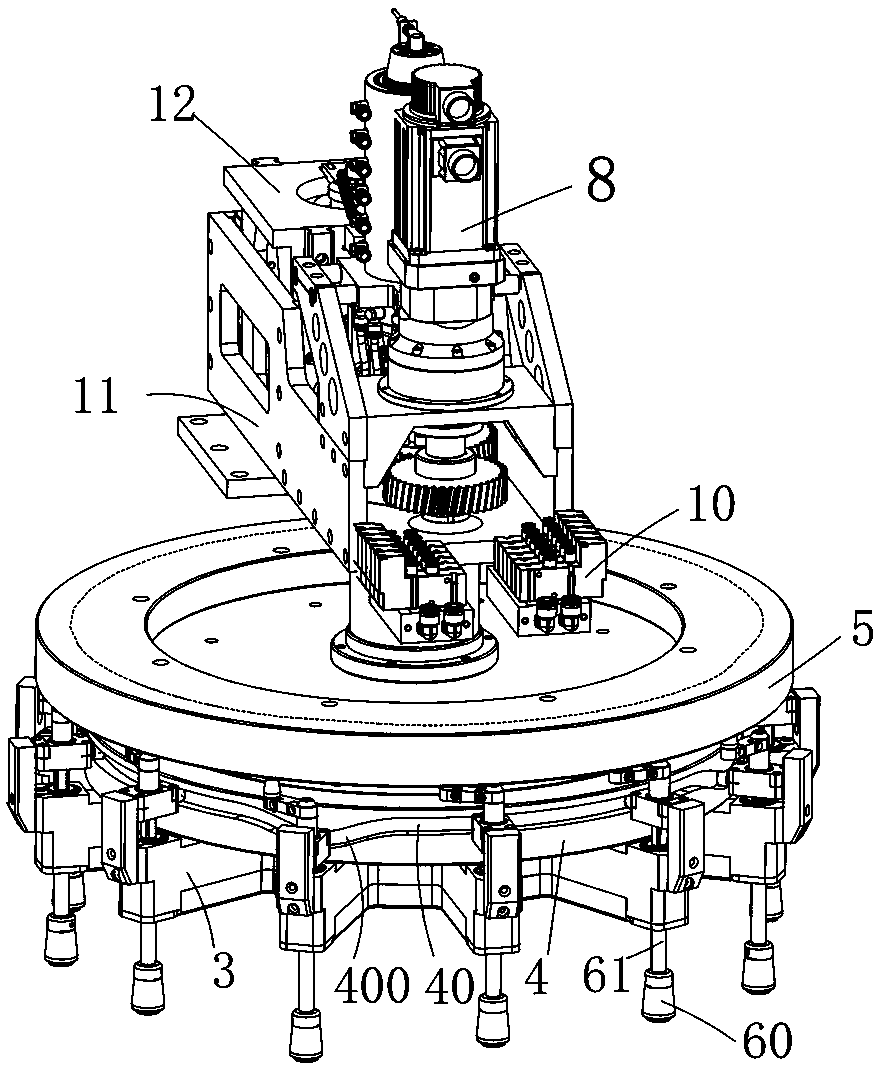

[0022] Such as figure 1 and figure 2 As shown, this orientation-maintaining rotary transfer manipulator A is installed on the frame B and is between the two devices that need to be linked, such as Figure 7 As shown, the orientation-maintaining rotary transfer manipulator links the pillow packaging machine with the cartoning machine, so that the pillow package produced by the pillow packaging machine is transferred to the cartoning machine through the orientation-maintaining rotary transfer robot A, thereby completing the pillow packaging box.

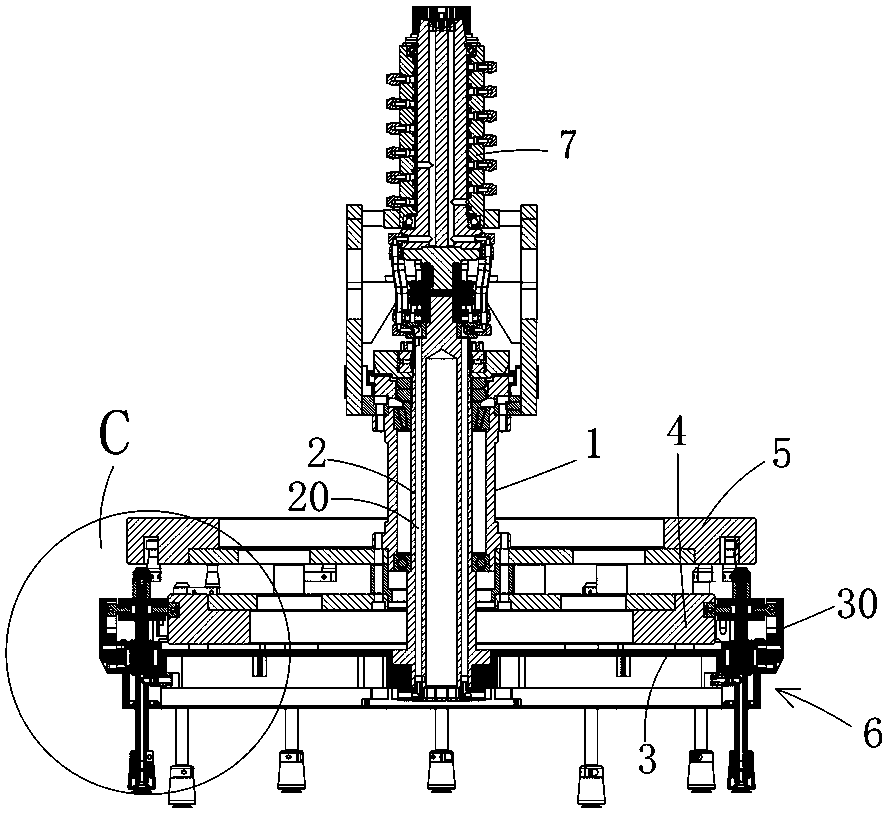

[0023] Such as figure 2 and image 3 As shown, this orientation-maintaining rotary transfer manipulator A includes a main base 1 (supporting flange), a rotating shaft 2, a rotating frame 3, a suction nozzle mechanism 6, and a rotating power source 8 (anything involving a power source includes a motor, Cylinder and other driving equipment), the rotating shaft 2 is installed in the main seat 1 and connected with the rotating power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com