A fuse assembly and its sheath and connector

A technology of fuses and connectors, which is applied in the direction of connections, components of connection devices, electrical components, etc., can solve problems such as low efficiency, and achieve the effects of easy and fast operation, simple structure, and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

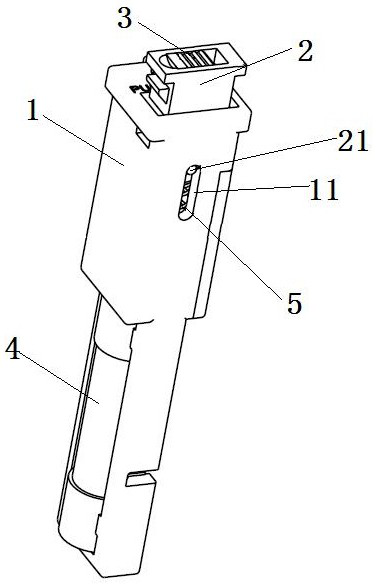

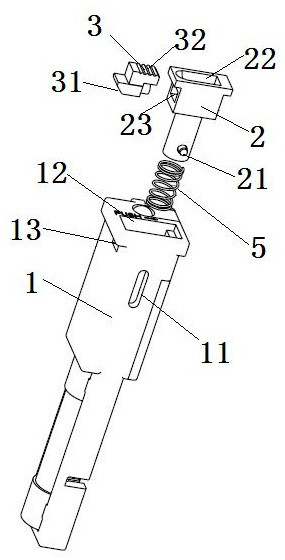

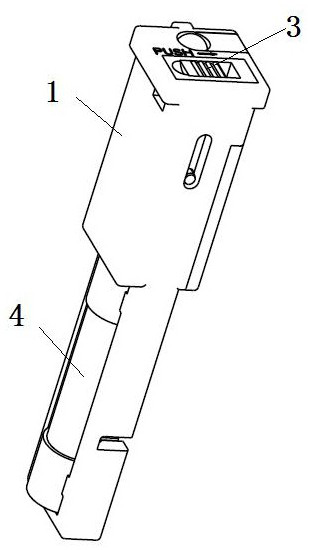

[0032] Example of the fuse assembly of the present invention, such as Figure 1 to 3 As shown in the connector, the fuse assembly is mounted in the connector, mainly including the insulator 4 and the sheath for accommodating the fuses 4, in the present embodiment, the insurance pipe is inserted into the connector housing in the axial direction thereof, corresponding The sheath is a long strip structure.

[0033] For jackets, it includes an insulator 1, and the insulator 1 is a long strip structure, such as figure 2 As shown, in the front end of the sheath insertion connector housing, in the present embodiment, the front end of the insulator 1 is provided with a receiving groove extending in the front-rear direction, and the fuse 4 is fixed in the accommodating groove. in. At the same time, the rear end of the insulator 1 is also provided with a receiving hole 12 extending in the front and rear directions, and the receiving hole 12 is a rear end opening, a front end closed blind hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com