Oil and gas cylinder for multipurpose vehicle and user method of oil and gas cylinder

A technology of multi-functional vehicles and oil-air cylinders, which is applied to vehicle parts, elastic suspensions, suspensions, etc., can solve the problems of inability to lift or lift the axle, achieve ingenious design, strong practicability, and improve the road surface through performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1 - passing a vertical obstacle

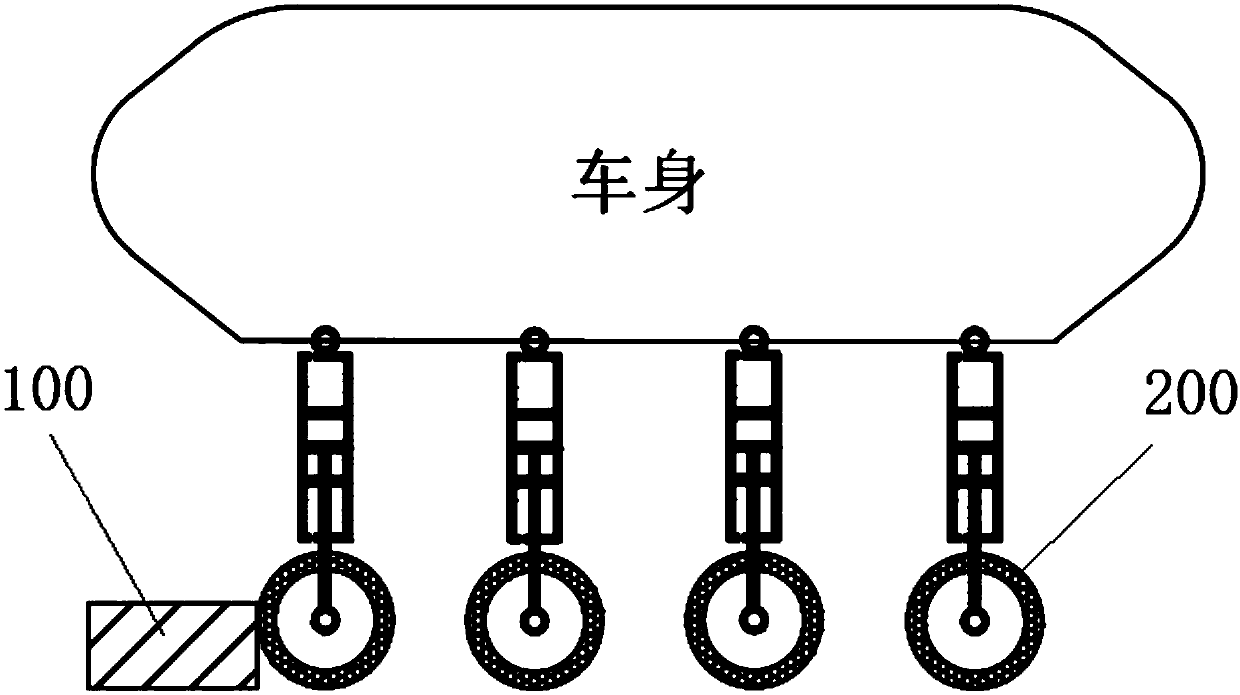

[0033] Such as image 3 and Figure 4 As shown, when the car moves at a speed V and encounters an obstacle 100 whose height exceeds the radius of the wheel, since the driving force of the whole vehicle cannot generate an upward component on the front wheel (except for the upward component generated by the rotation of the front wheel), In this way, the car cannot pass through obstacles normally.

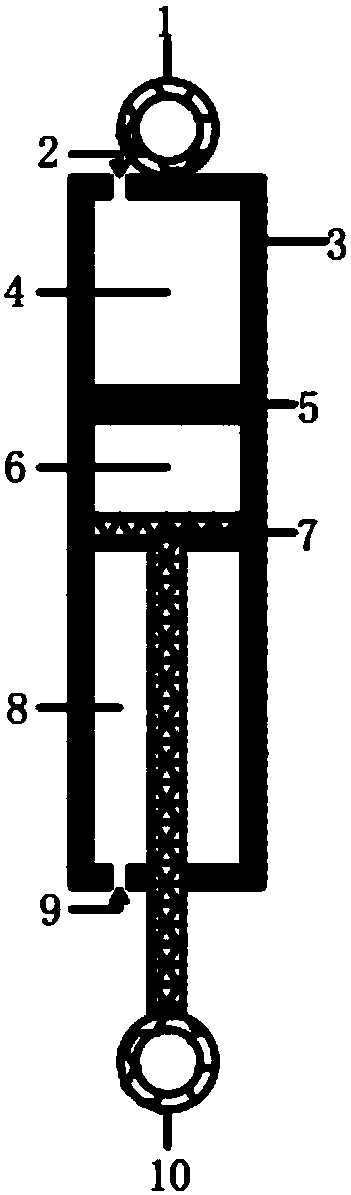

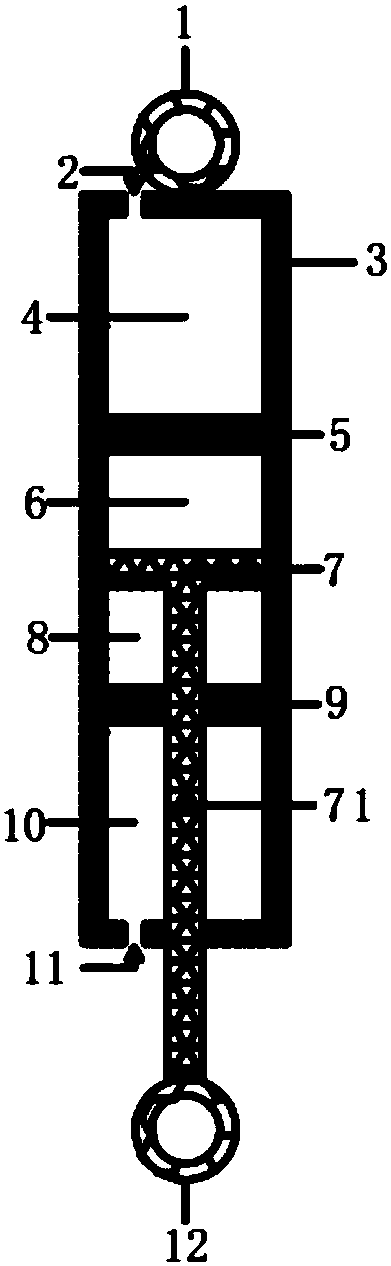

[0034] At this time, by manipulating the trigger device in the cab, the first hydraulic oil chamber 4 in the multi-function vehicle oil cylinder connected to the front axle will release hydraulic oil, the second hydraulic oil chamber 10 will be filled with hydraulic oil, and the second hydraulic oil chamber 10 will be filled with hydraulic oil. The pressure in the oil chamber 10 rises to make the piston 7 go up, thereby lifting the front axle, making the front axle wheel 200 off the ground, and the height of the axle from the ground e...

example 2

[0035] Example 2 - Through the trench

[0036] Such as Figure 5 As shown, when the car moves at a speed V and encounters a ditch 300 with a width greater than the diameter of the wheel, the wheel 200 will stretch the suspension system under the action of its own gravity and descend. Unable to get upward component force (except for the upward component force produced by the rotation of the front wheels), the car cannot pass through the ditch normally.

[0037] At this time, by manipulating the trigger device in the cab, the first hydraulic oil chamber 4 in the multi-function vehicle oil cylinder connected to the front axle will release hydraulic oil, the second hydraulic oil chamber 10 will be filled with hydraulic oil, and the second hydraulic oil chamber 10 will be filled with hydraulic oil. The pressure in the oil chamber 10 rises to make the piston 7 go up, thereby lifting the front axle and making the front axle wheel 200 rise. The height of the axle from the ground is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com