Chain type manual sewing machine

A beading machine and chain technology, which is applied to sewing machine components, ferrule mechanisms for sewing machines, and thread-cutting mechanisms in sewing machines, etc., can solve problems such as bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the drawings.

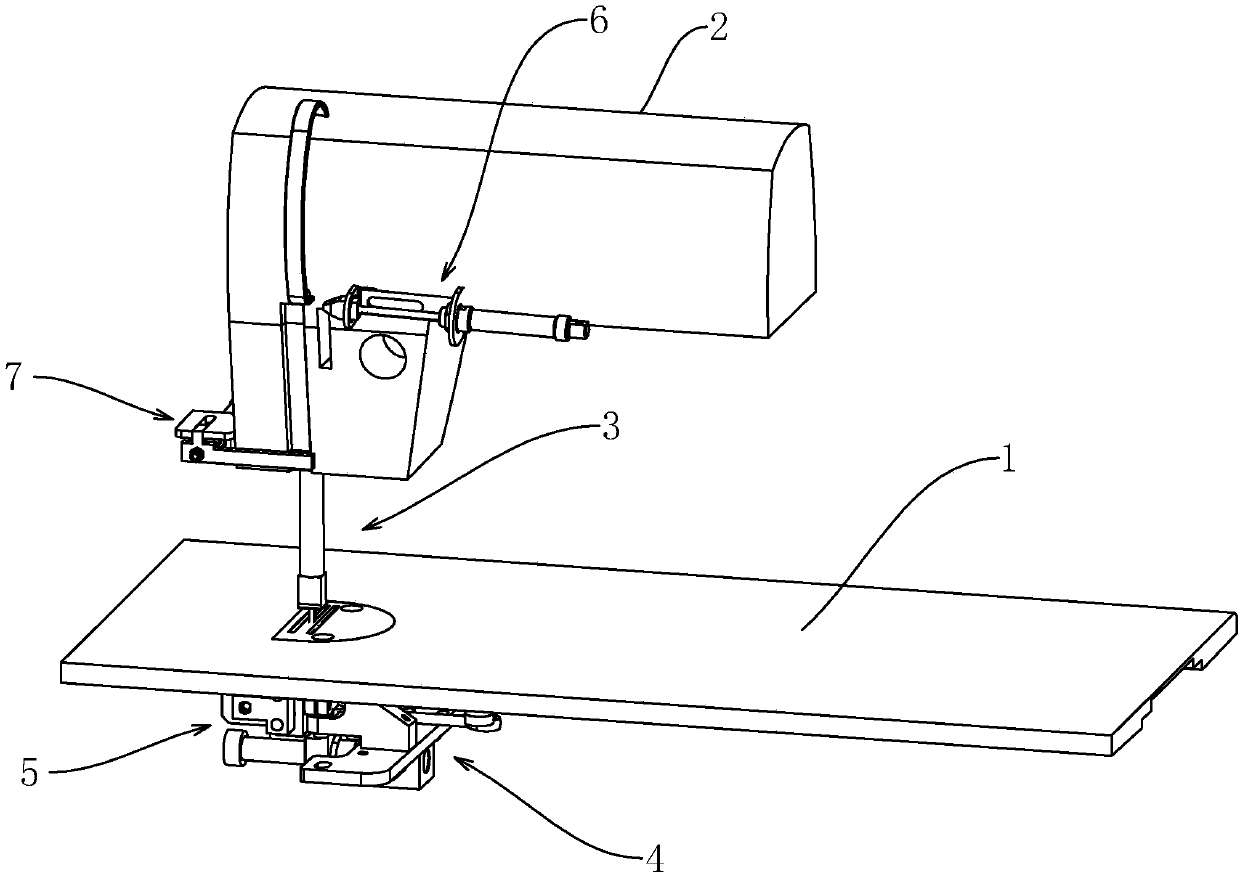

[0044] Such as figure 1 As shown, a chain-type bead edge machine includes a mounting frame 1 and a machine head 2 located on the mounting frame 1. A needle mechanism 3 is installed under the head 2 and a matching needle mechanism 3 is installed under the mounting frame 1. The hook thread hooking device 4 and the thread cutting device 5 for cutting yarns. The machine head 2 is also equipped with a thread loosening device 6 and a thread pressing device 7. When the thread loosening device 6 loosens the thread, the thread pressure device 7 compresses the wool to prevent the wool from falling out of the needle mechanism 3.

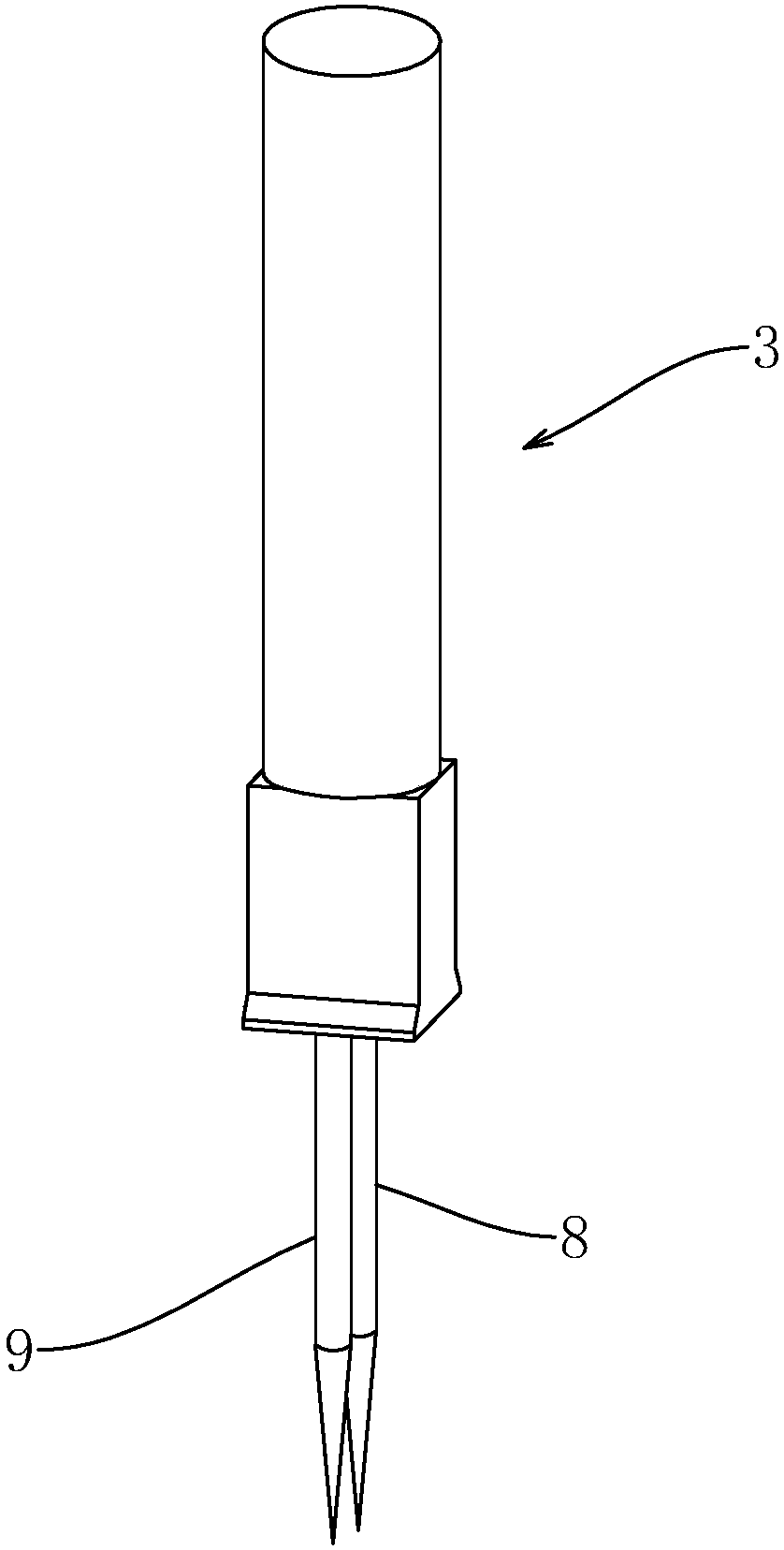

[0045] Such as figure 2 As shown, the sewing needle mechanism 3 includes a threading needle 8 and a crochet needle 9 side by side, and a space is left between the threading needle 8 and the crochet needle 9.

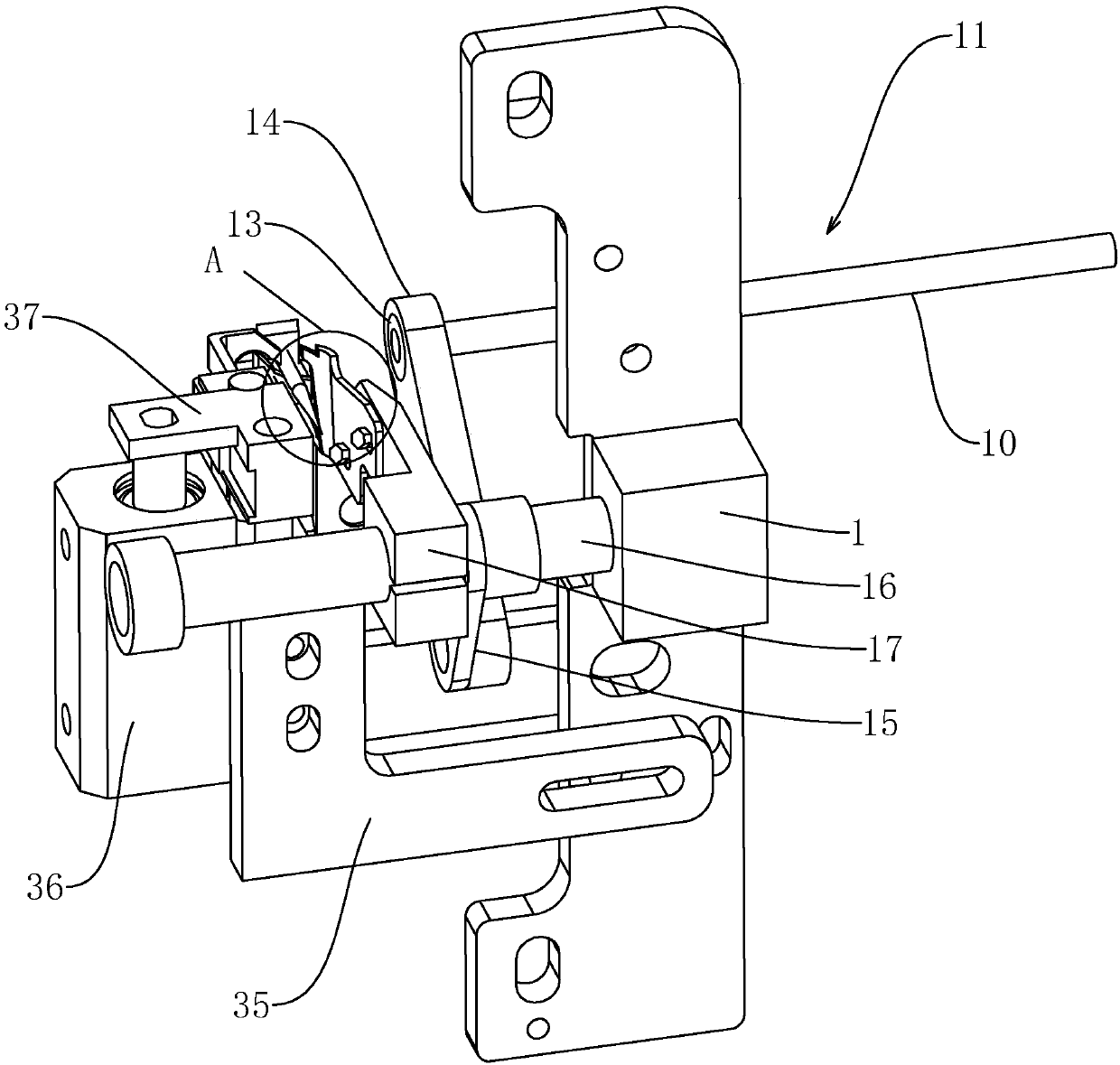

[0046] Such as image 3 with Figure 4 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com