Comprehensive checking tool capable of detecting true position of elliptical hole

A technology of comprehensive inspection tools and elliptical holes, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of inability to meet the requirements of mass production and full inspection, slow detection speed, production waste, etc., and improve processing Effects of quality and measurement accuracy, improvement of life, and improvement of economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

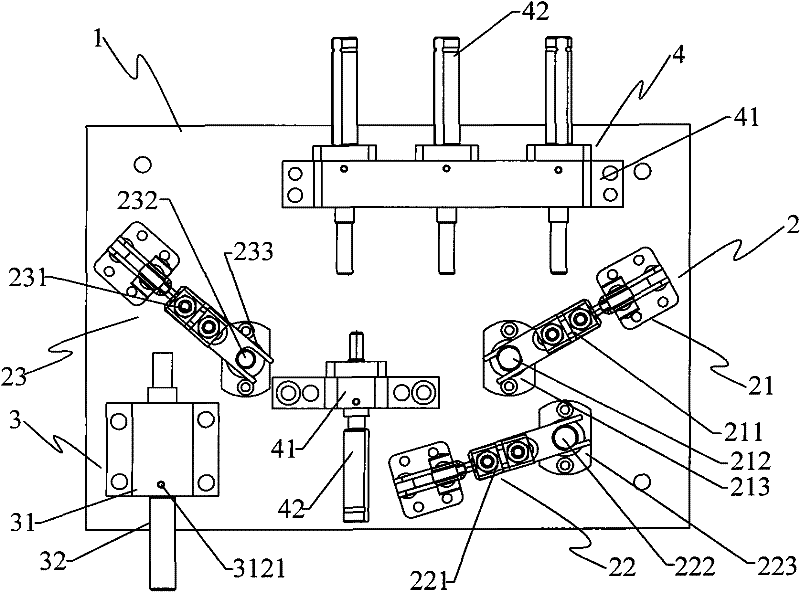

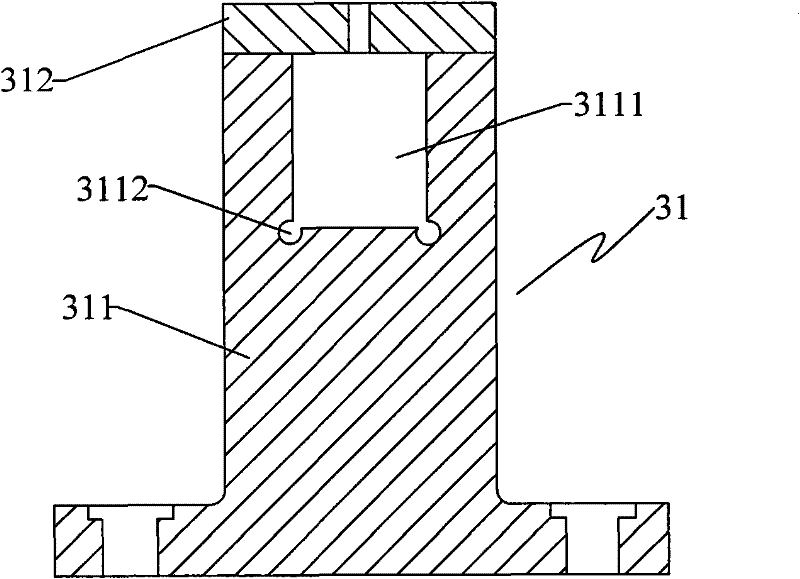

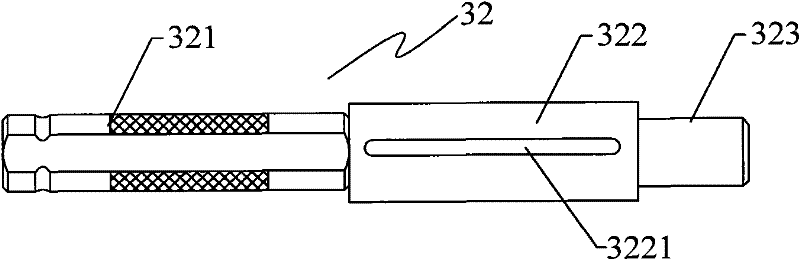

[0022] Such as Figure 1~4 As shown, the comprehensive inspection tool for detecting the position of an elliptical hole according to the present invention includes a supporting base 1, and the supporting base 1 is provided with a positioning and clamping device 2, an elliptical hole measuring device 3 and a round hole measuring device 4 .

[0023] The above-mentioned positioning and clamping device 2 includes a first positioning and clamping device 21, a second positioning and clamping device 22 and a third positioning and clamping device 23, the three are respectively arranged on the angular direction positions of the workpiece, and the first positioning and clamping The device 21 and the second positioning and clamping device 22 are respectively provided with quick-change clamps 211, 221, positioning cylinders 212, 222 and positioning sleeves 213, 223 for use in cooperation, and the third positioning and clamping device 23 is provided with quick-change clamps for use in coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com