Horizontal well cluster perforation staged fracturing method

A staged fracturing and horizontal well technology, applied in the field of horizontal well fracturing, can solve the problems of less number of fractures, low complexity of fractures, small fracture length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

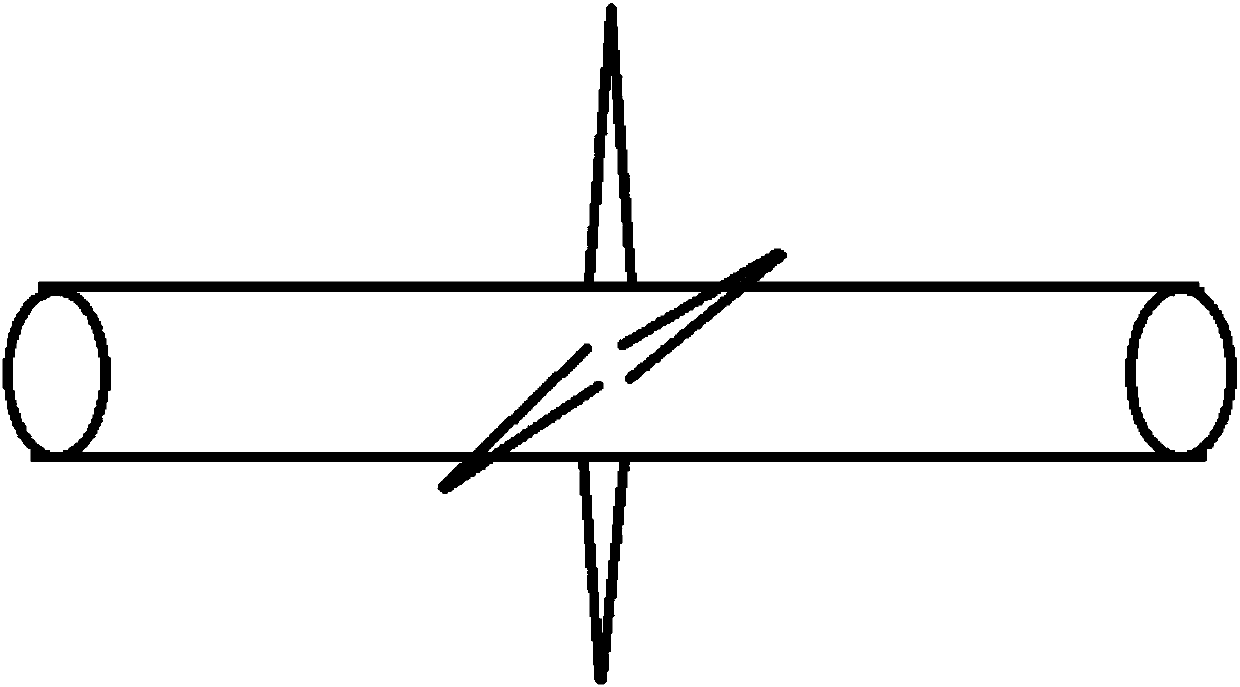

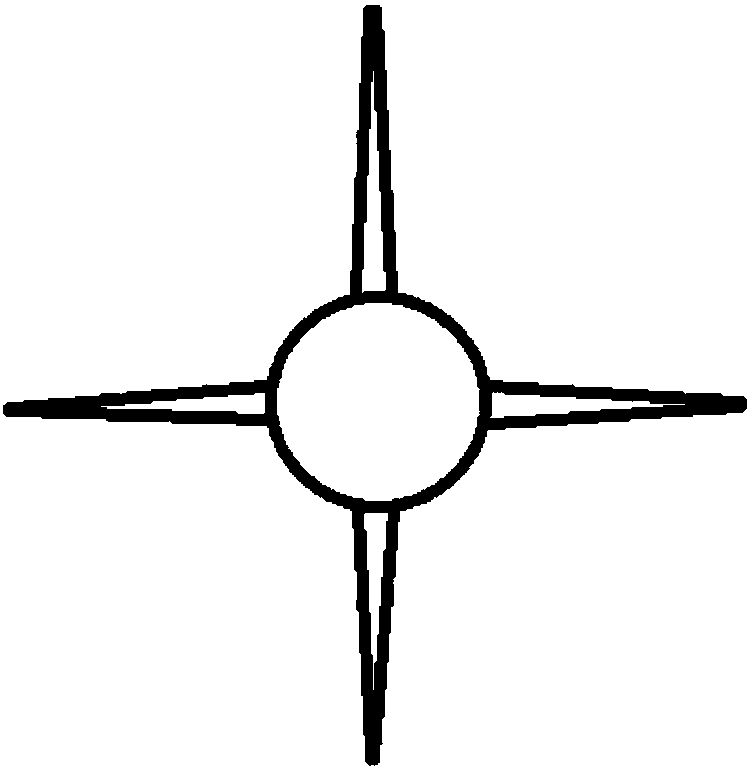

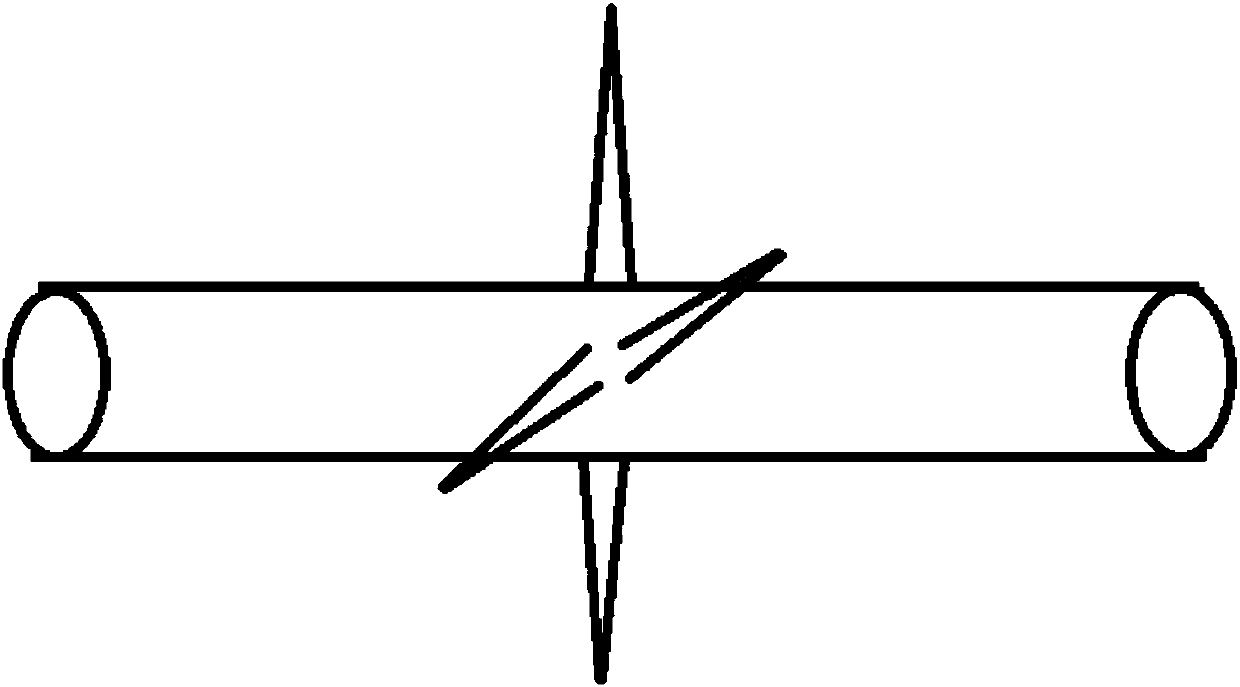

Image

Examples

Embodiment

[0078] In Well A, the lithology of the target interval is gray fluorescent fine sandstone with pebbles, and natural fractures are well developed. The fracturing section of the target layer is 3128.2-3589.7m, the average Young's modulus of the reservoir is 23.2GPa, and the average Poisson's ratio is 0.22; the stress difference between the target layer and the upper barrier is about 8MPa, and the stress difference between the target layer and the lower barrier is about 4MPa ; The target layer temperature is 112°C. In order to understand the gas-bearing property and production capacity of the target layer, and to carry out the next step of exploration and evaluation work in this block, the fracturing scheme design and on-site pilot of the well were carried out by referring to the process method proposed in this patent and combining with the actual situation of the well. The specific implementation method and effect of the test are as follows:

[0079] (1) Reservoir parameter eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com