Gas heater

A heater and gas technology, applied in the field of heaters, can solve problems such as potential safety hazards, threats to personal safety, large gas flow, etc., and achieve high ignition efficiency and safe ignition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

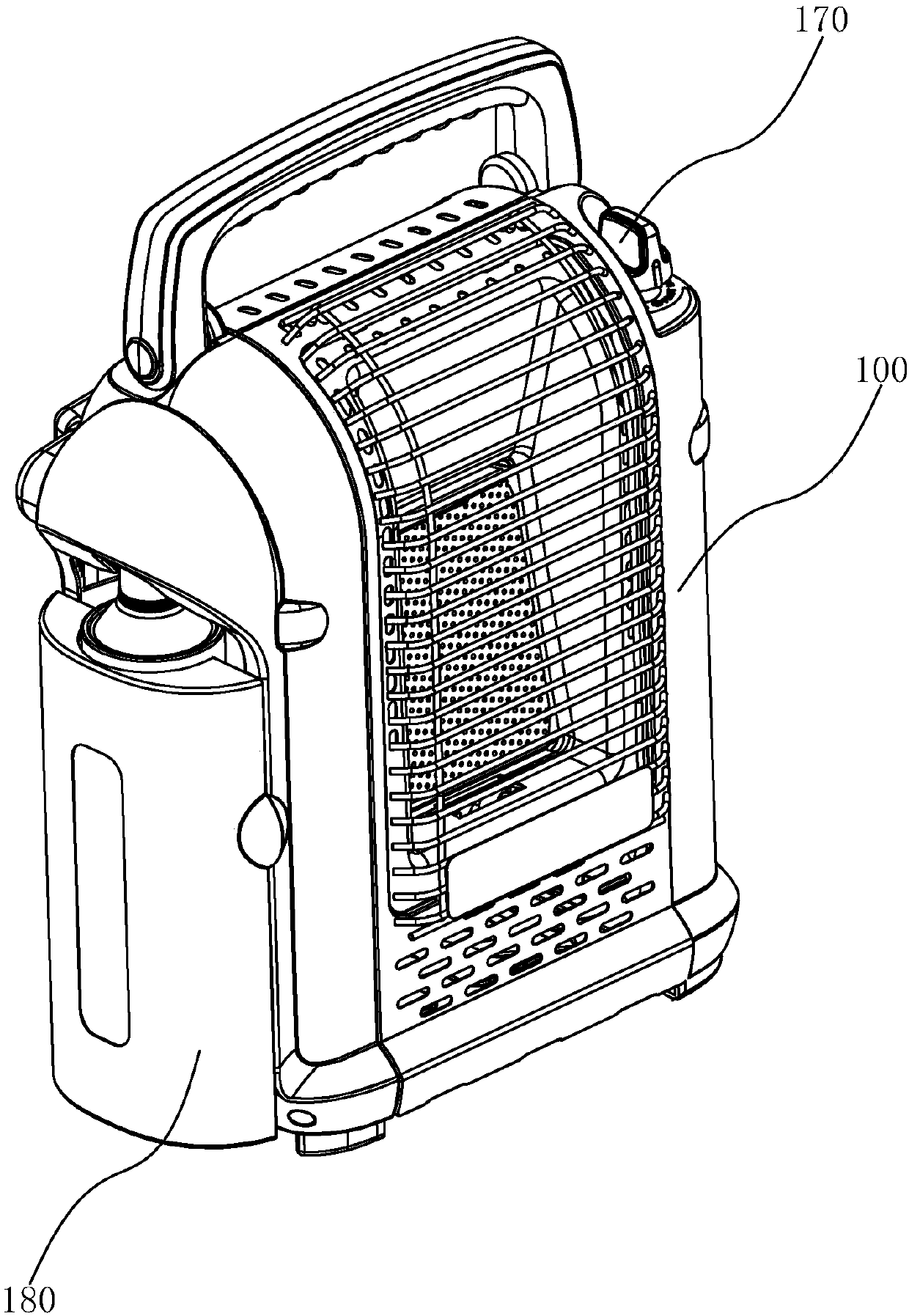

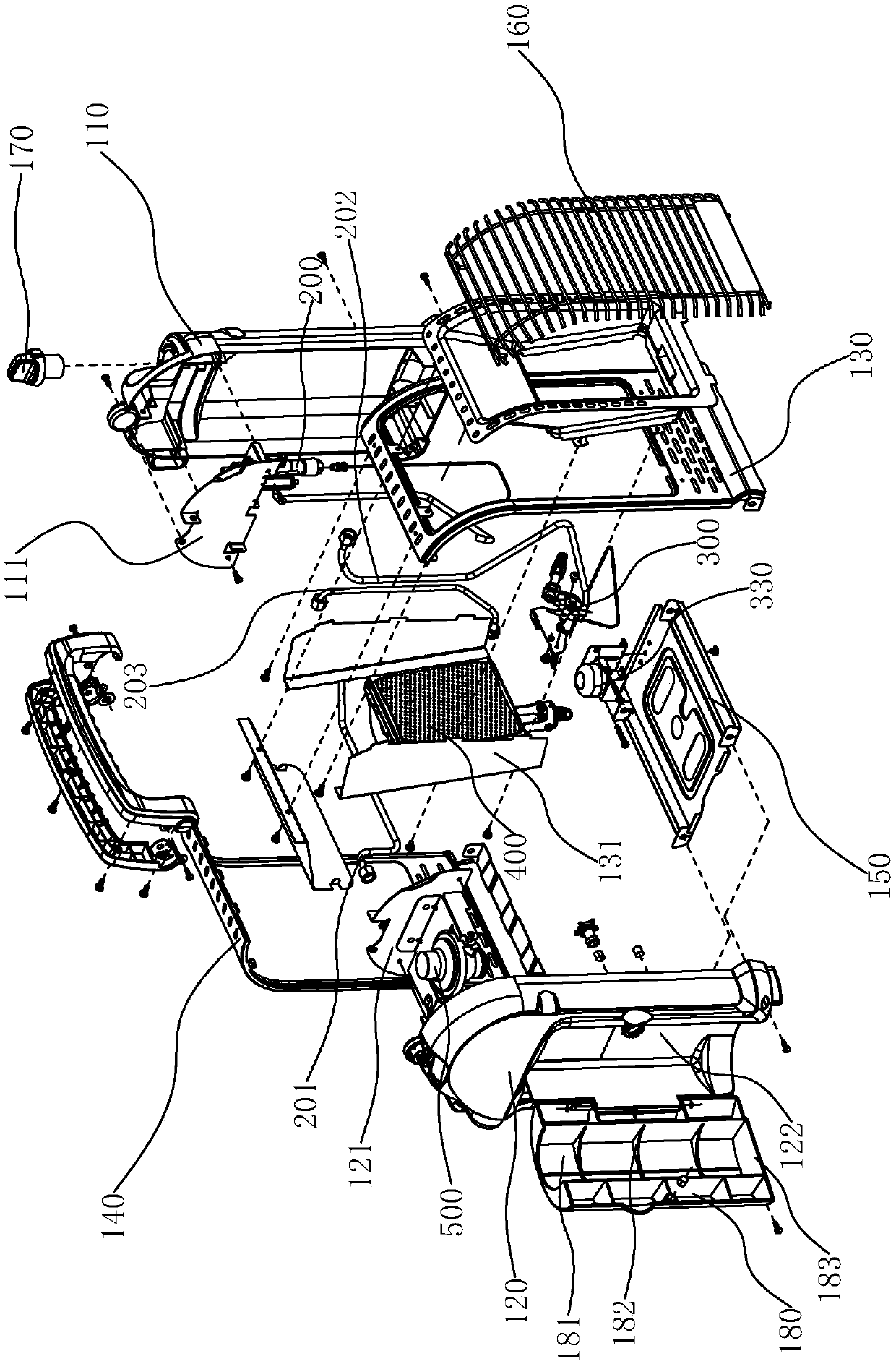

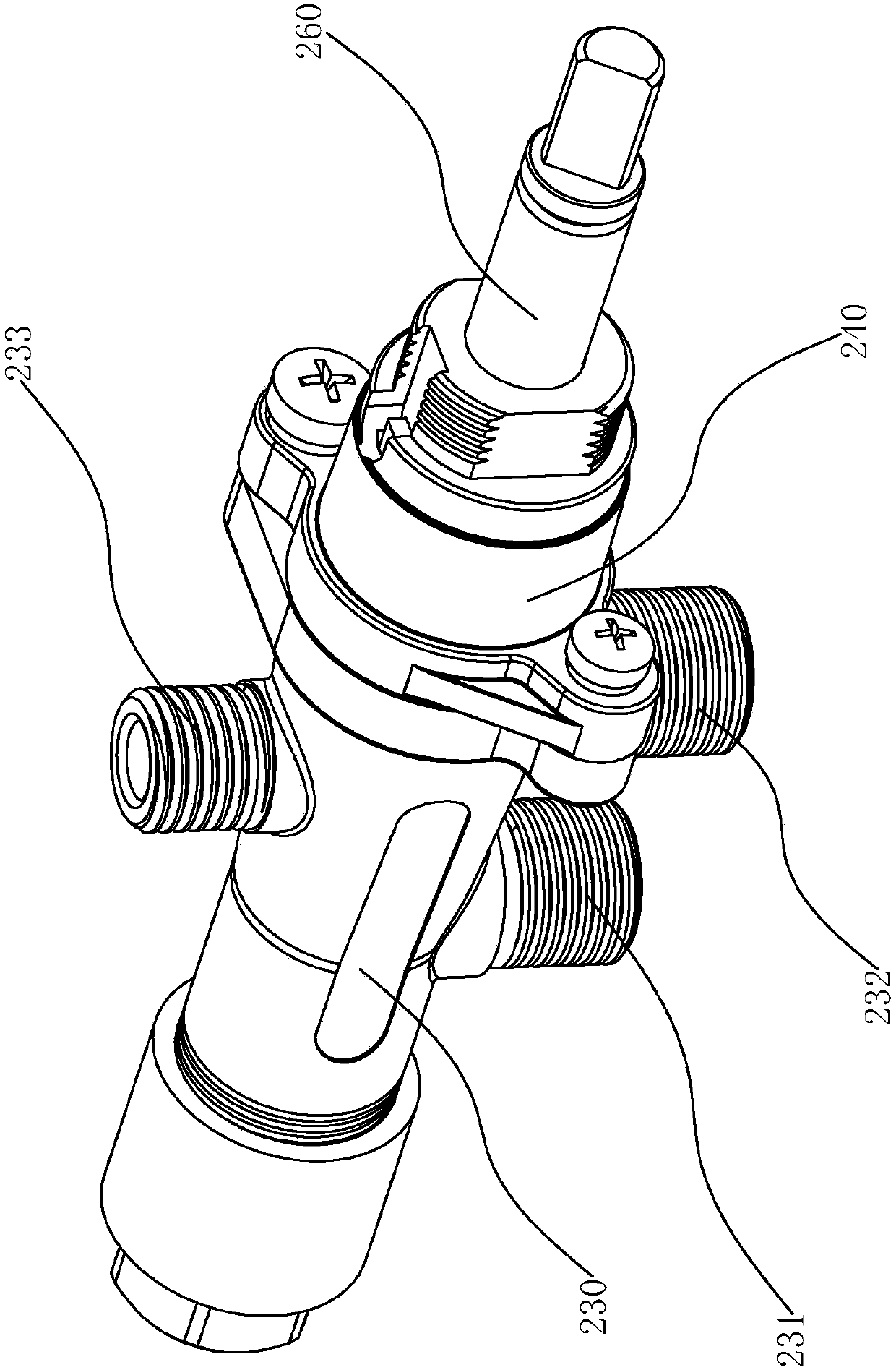

[0031] Such as figure 1 , figure 2 As shown, a gas heater of the present invention includes a casing 100, a control valve 200 arranged in the casing 100 and fixedly connected to the casing 100, an oxygen deficiency protection device 300, and a burner 400. The casing 100 includes a left casing 110 , the right housing 120, the front cover 130 and the rear cover 140 fixedly connected with the left housing 110 and the right housing 120 respectively, and the bottom plate 150 connecting the left housing 110, the right housing 120, the front cover 130 and the rear cover 140, The control valve 200 is installed on the left housing 110 through the first mounting bracket, the burner 400 is fixedly connected to the front cover 130 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com