A Method for Quickly Testing the Wrinkle Recovery Performance of Fabrics

A fabric and fast technology, applied in the direction of applying stable bending force to test the strength of materials, measuring devices, strength characteristics, etc., can solve the problems of large error in test results, short test time, long test time, etc., to reduce the test Effects of error, reduced compaction and recovery time, accurate crease recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] To measure the average angle of return of the fabric sample to be tested, the steps are as follows:

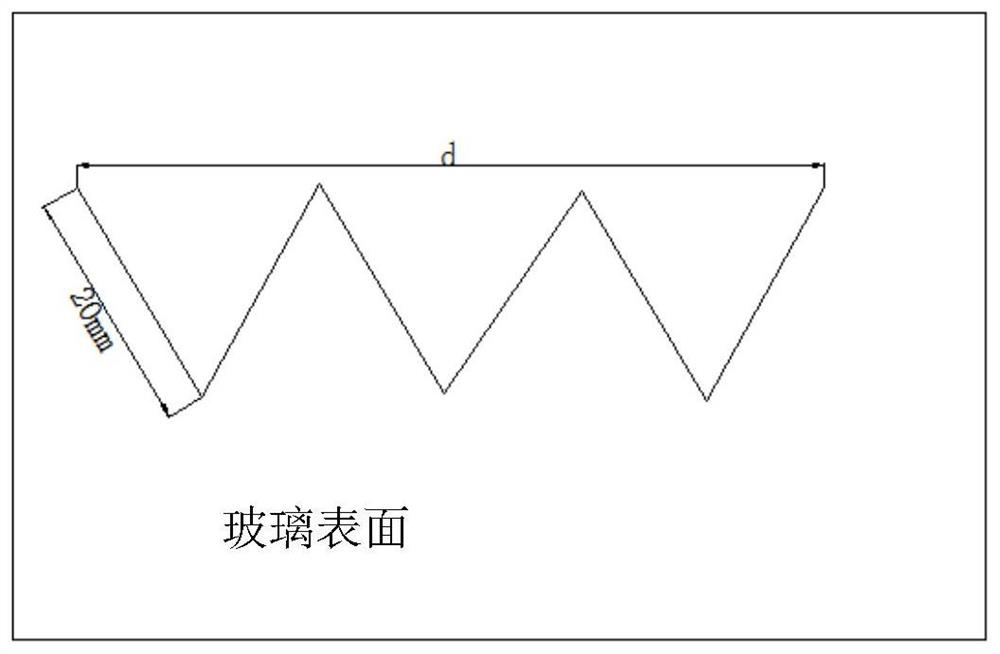

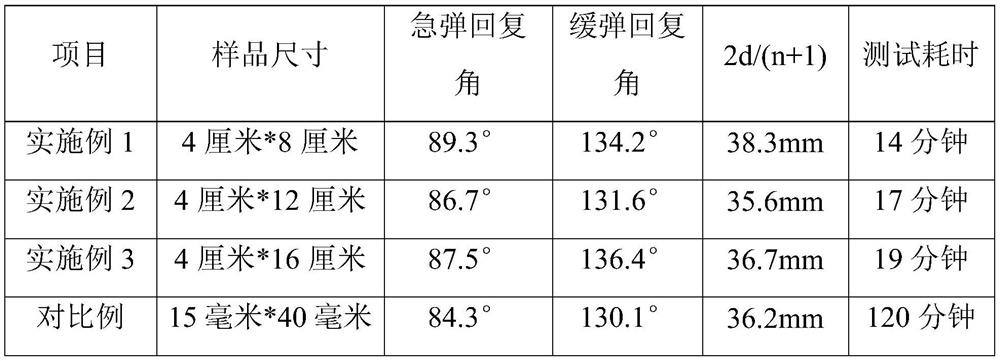

[0045] (1) Folding in half: the size of the fabric sample is 4 cm * 8 cm, and the front and back of the fabric sample are respectively laid with release paper (plastic film, thickness 0.08 mm), and then folded in half every 2 cm along the length direction. Fold in half alternately, and fold 3 times in total, that is, n=3;

[0046] (2) Compaction: put the weight on the folded fabric sample, and the compaction time is 5 minutes;

[0047] (3) Reply: remove the weight, take out the release paper, and place the side of the fabric sample flat on the glass surface;

[0048] (4) Measurement: Measure the included angle formed by the two sides of the folded fabric 3 times by photographic method. Specifically, measure the rapid spring recovery angle after 5 seconds of recovery and calculate the average value of 89.3°, and measure the slow spring recovery angle after 5 minutes of ...

Embodiment 2

[0050] To measure the average angle of return of the fabric sample to be tested, the steps are as follows:

[0051] (1) Folding in half: the size of the fabric sample is 4 cm * 12 cm, and the front and back of the fabric sample are respectively laid with release paper (plastic film, thickness 0.09mm), and then folded in half every 2 cm along the length direction. Fold in half alternately, and fold 5 times in total (such as figure 1 Shown), that is, n=5;

[0052] (2) Compaction: put the weight on the folded fabric sample, and the compaction time is 5 minutes;

[0053] (3) Reply: remove the weight, take out the release paper, and place the side of the fabric sample flat on the glass surface;

[0054] (4) Measurement: Measure the included angle formed by folding the two sides of the fabric 5 times by photographic method. Specifically, measure the rapid spring recovery angle after 5 seconds of recovery and calculate the average value of 86.7°, and measure the slow spring recover...

Embodiment 3

[0056] To measure the average angle of return of the fabric sample to be tested, the steps are as follows:

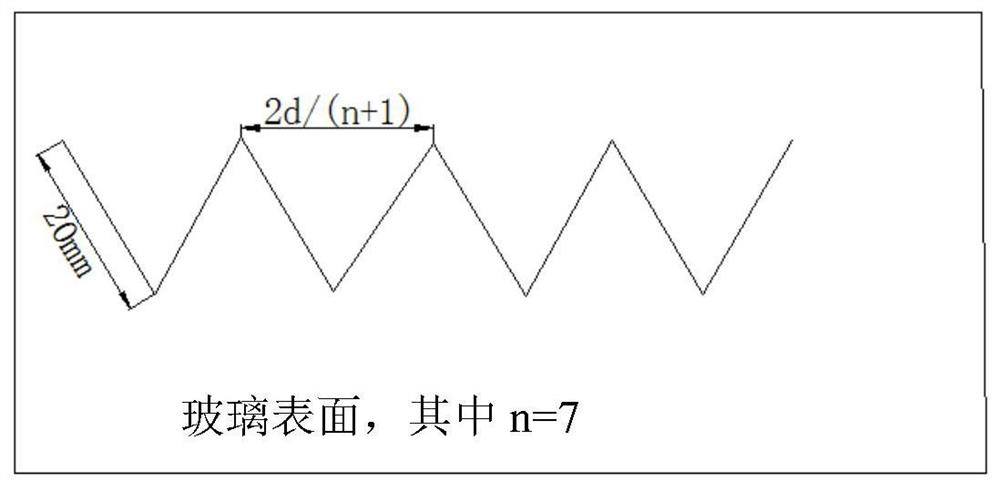

[0057] (1) Folding in half: the size of the fabric sample is 4 cm * 16 cm. The front and back of the fabric sample are respectively laid with release paper (plastic film, thickness 0.1 mm), and then folded in half every 2 cm along the length direction. Fold in half alternately, and fold 7 times in total (such as figure 2 Shown), namely n=7;

[0058] (2) Compaction: put the weight on the folded fabric sample, and the compaction time is 5 minutes;

[0059] (3) Reply: remove the weight, take out the release paper, and place the side of the fabric sample flat on the glass surface;

[0060] (4) Measurement: Measure the included angle formed by the two sides of the folded fabric 7 times by photographic method. Specifically, measure the rapid spring recovery angle after 5 seconds of recovery and calculate the average value of 87.5°, and measure the slow spring recovery angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com