Installation for optical inspection of glass containers at the outlet of a forming machine

A technology for optical inspection and glass containers, which is applied in scientific instruments, optical testing for flaws/defects, and material analysis through optical means, and can solve problems such as high cost, large footprint, and restrictions on installation at the exit of molding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

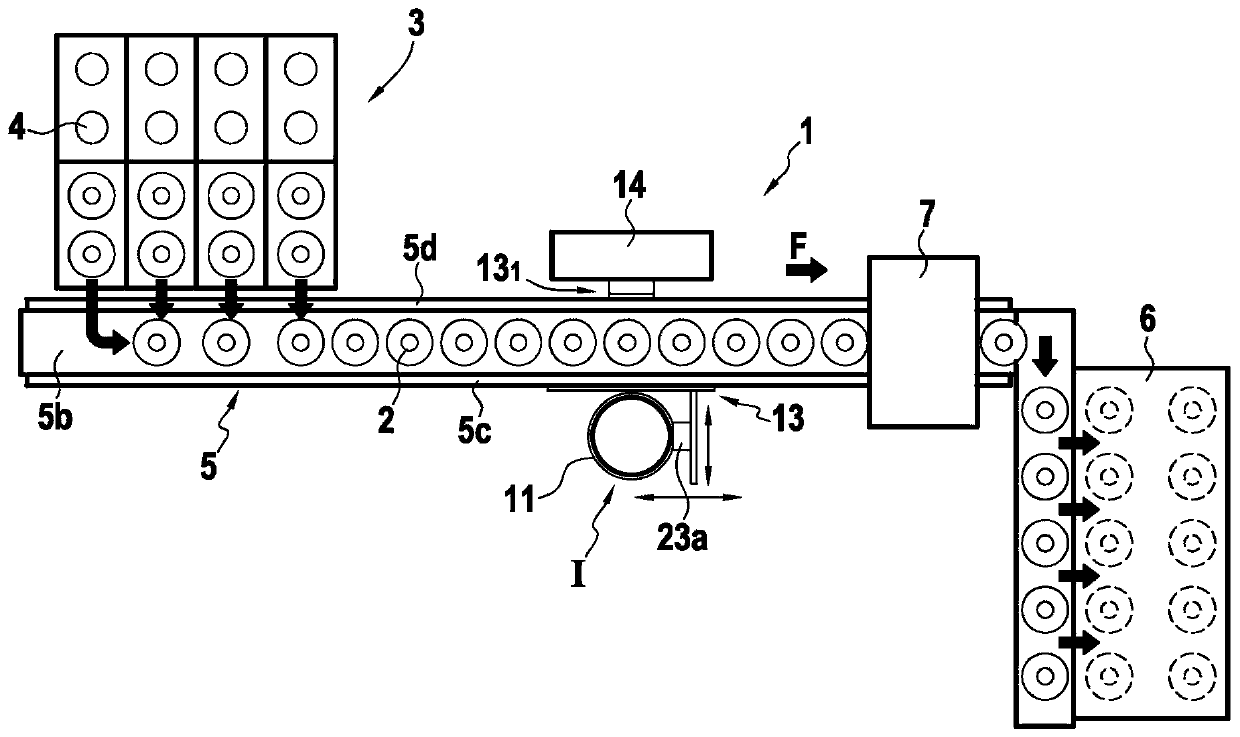

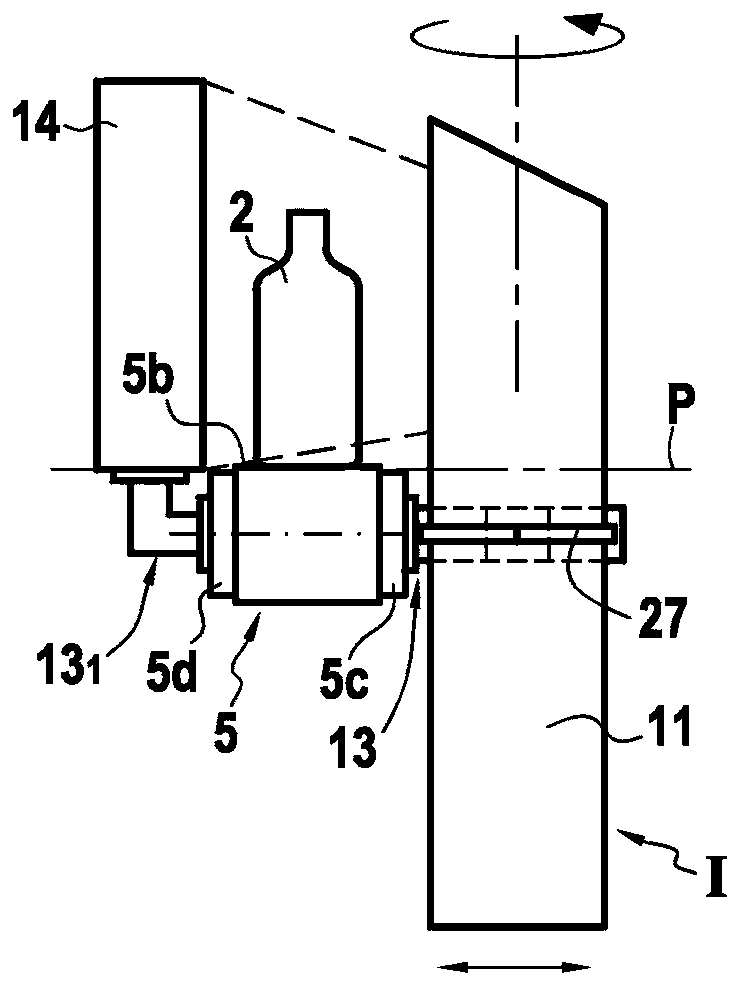

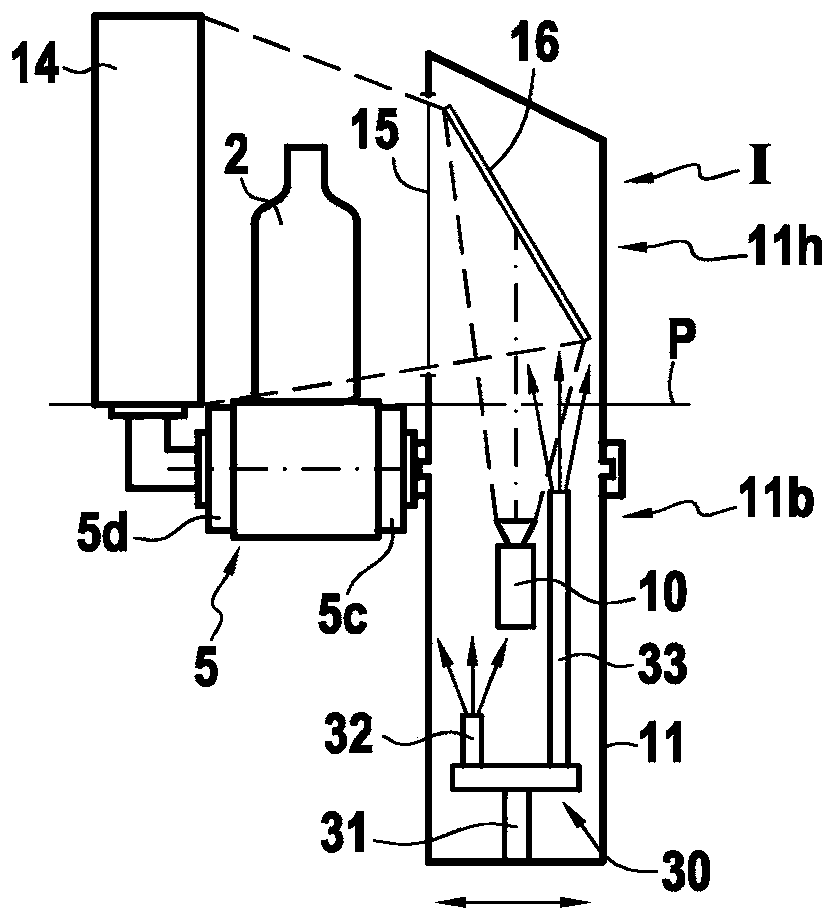

[0030] Such as figure 1 As shown more clearly in , the present invention provides an apparatus 1 which enables transparent or translucent containers 2, such as glass bottles or flasks, to be inspected while the containers are hot. The device 1 is positioned so as to be able to inspect containers 2 leaving a manufacturing or forming machine 3 of any known type. At the exit of the forming machine, the container 2 is at a high temperature, usually in the range of 300°C to 600°C.

[0031] In conventional manner, the forming machine 3 has a series of cavities 4 , each for forming a container 2 . In a known manner, the containers 2 just formed by the machine 3 are successively placed on an outlet conveyor 5 so as to form a row of containers. The containers 2 are transported in rows by a conveyor 5 in a conveying direction F, so as to pass successively through the various processing stations. As usual, the conveyor 5 has a fixed structure 5a standing on the floor S and supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com