Water-based negative oxygen ion internal wall paint production process system and process formula thereof

A negative oxygen ion and production process technology, applied in the field of coating technology, can solve the problems of insufficient fineness of the product, poor dispersion effect, increase of negative ion concentration, etc., and achieve the effect of simple structure and fine emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

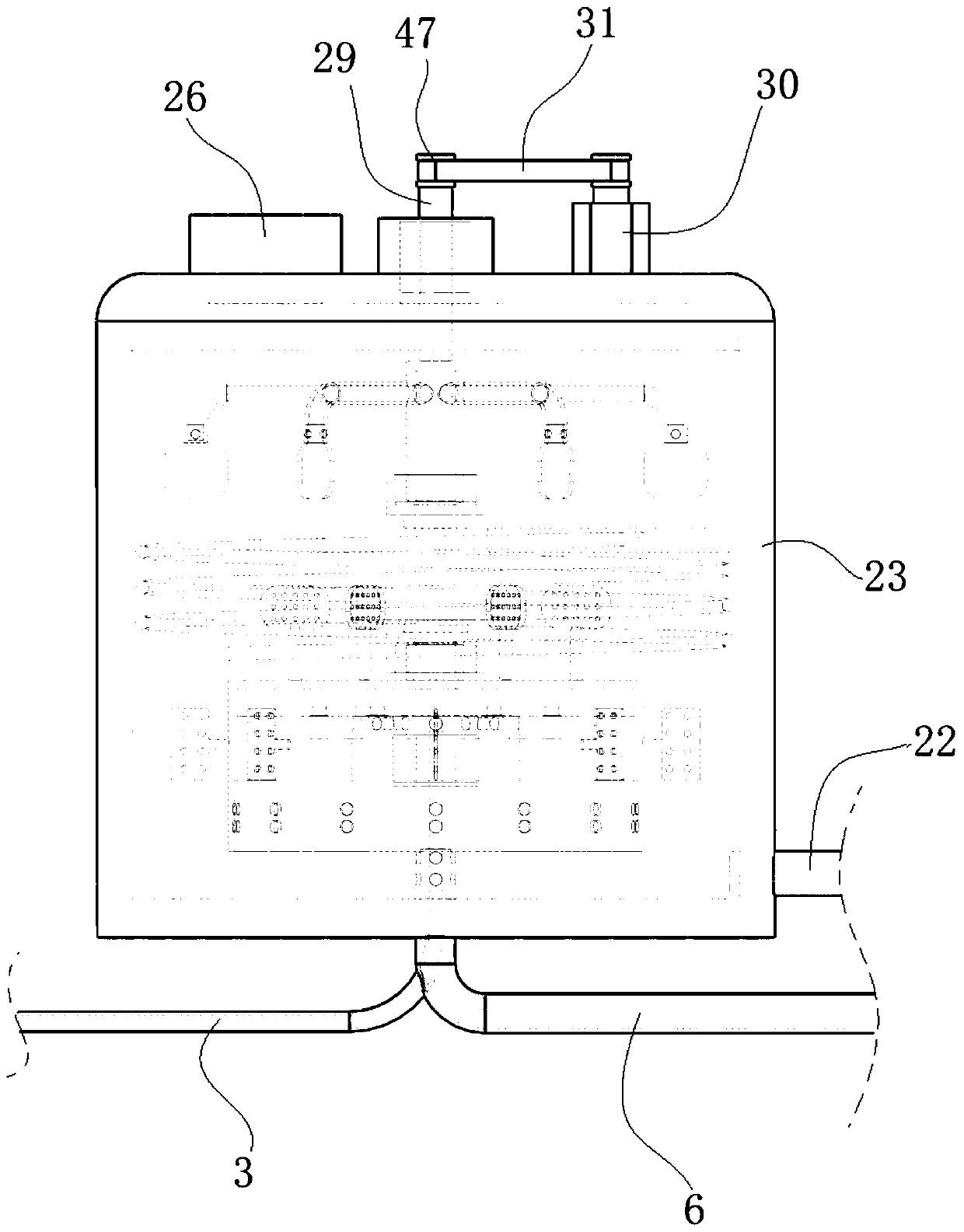

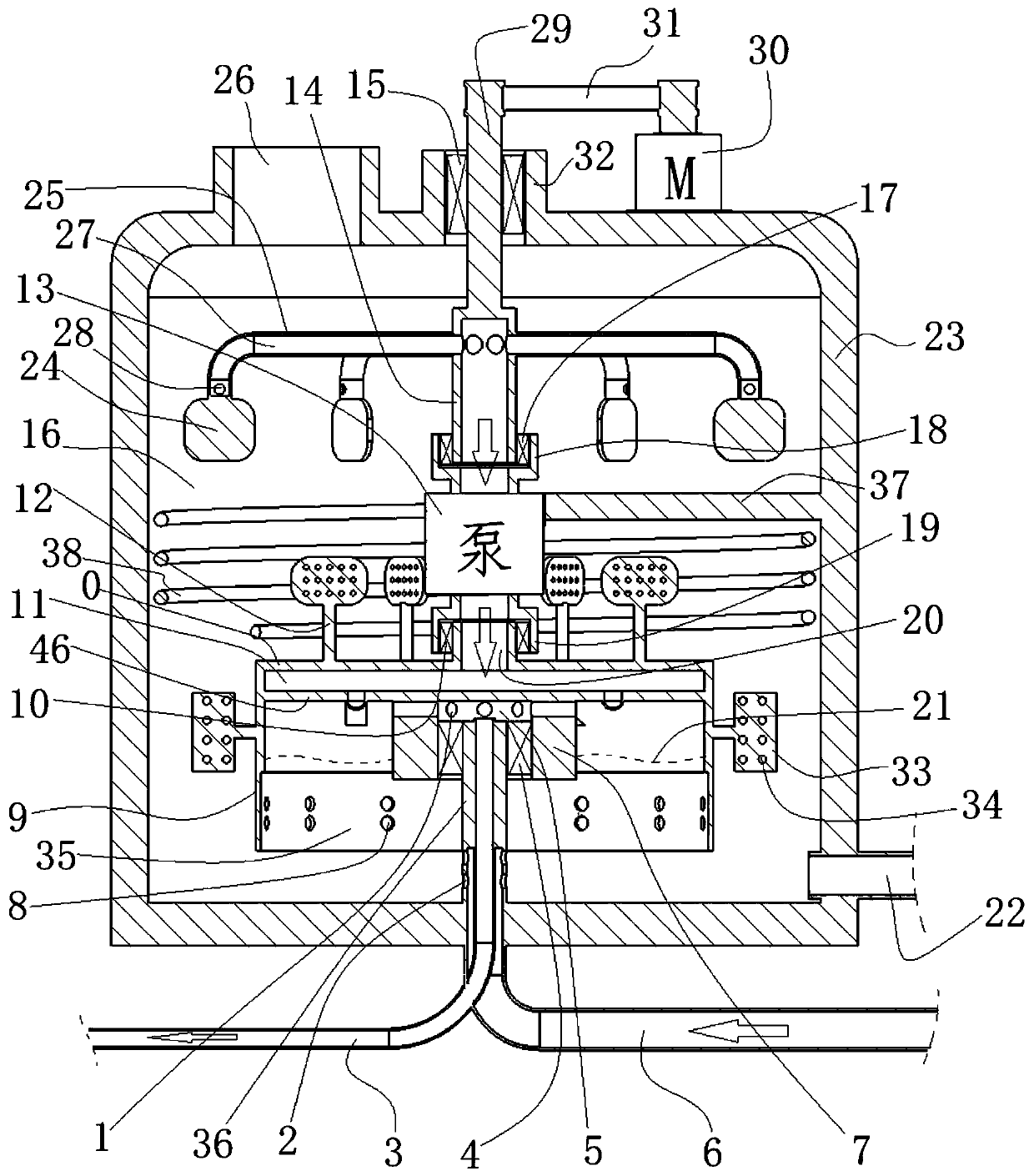

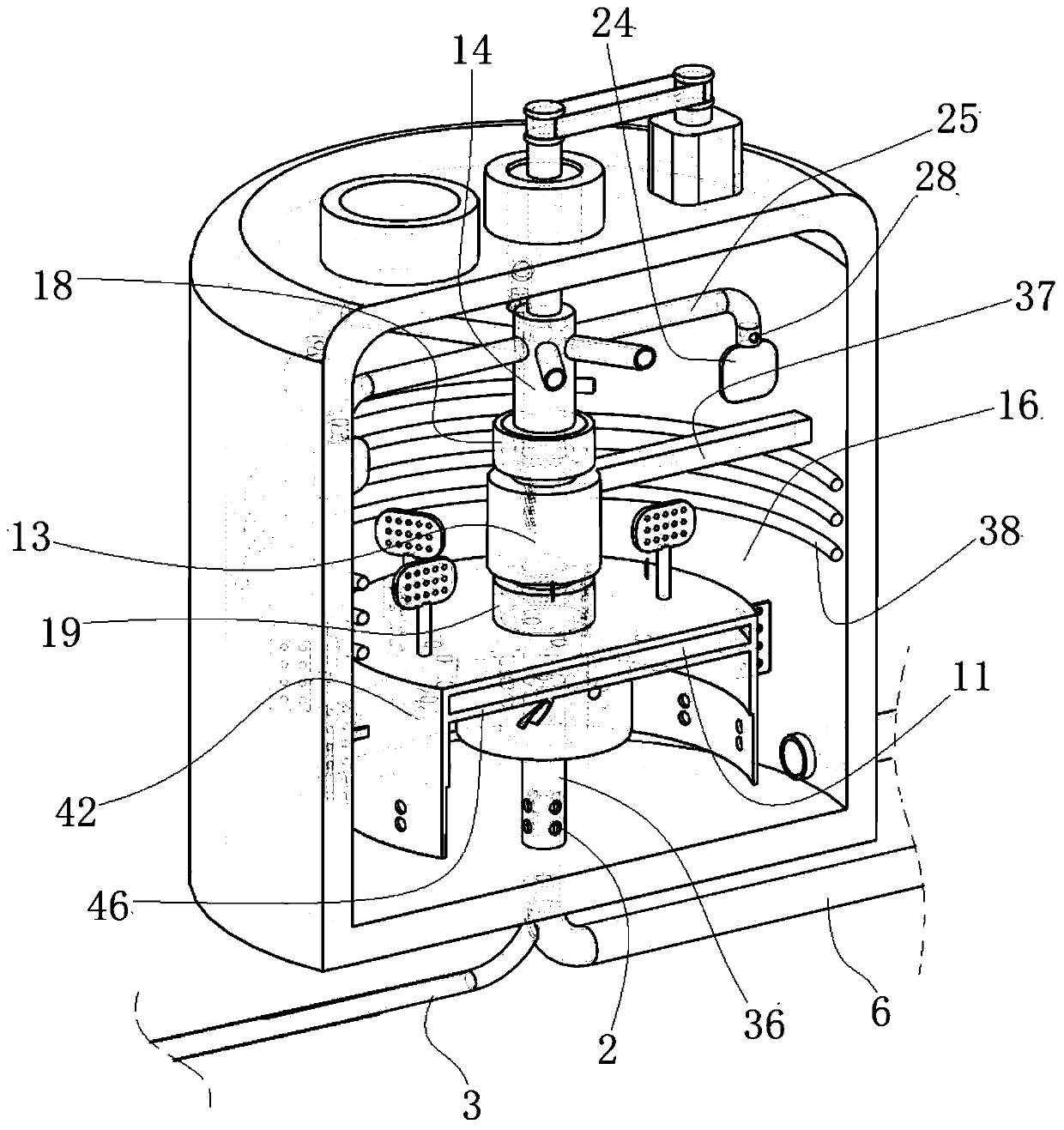

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] as attached Figures 1 to 6 Shown water-based negative oxygen ion interior wall paint production process system is characterized in that: comprise vertical columnar paint dispersion tank 23, the top side of described coating dispersion tank 23 is provided with feed inlet 26, and described coating dispersion Inside the tank of the tank 23 is a columnar paint dispersion chamber 16, which also includes a paint outlet pipe 22. The liquid inlet end of the paint outlet pipe 22 communicates with the bottom of the paint dispersion chamber 16, and a solenoid valve is installed on the paint outlet pipe 22. and a liquid suction pump; the central part of the paint dispersion chamber 16 is provided with a circulating liquid pump 13; it also includes a horizontal liquid pump support 37, and one end of the liquid pump support 37 is fixedly connected to the inner wall of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com