Gene sequencer

A gene sequencer and base technology, applied in the field of biochemistry, can solve the problems of high cost, high failure rate and complex structure of vibration suppression devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

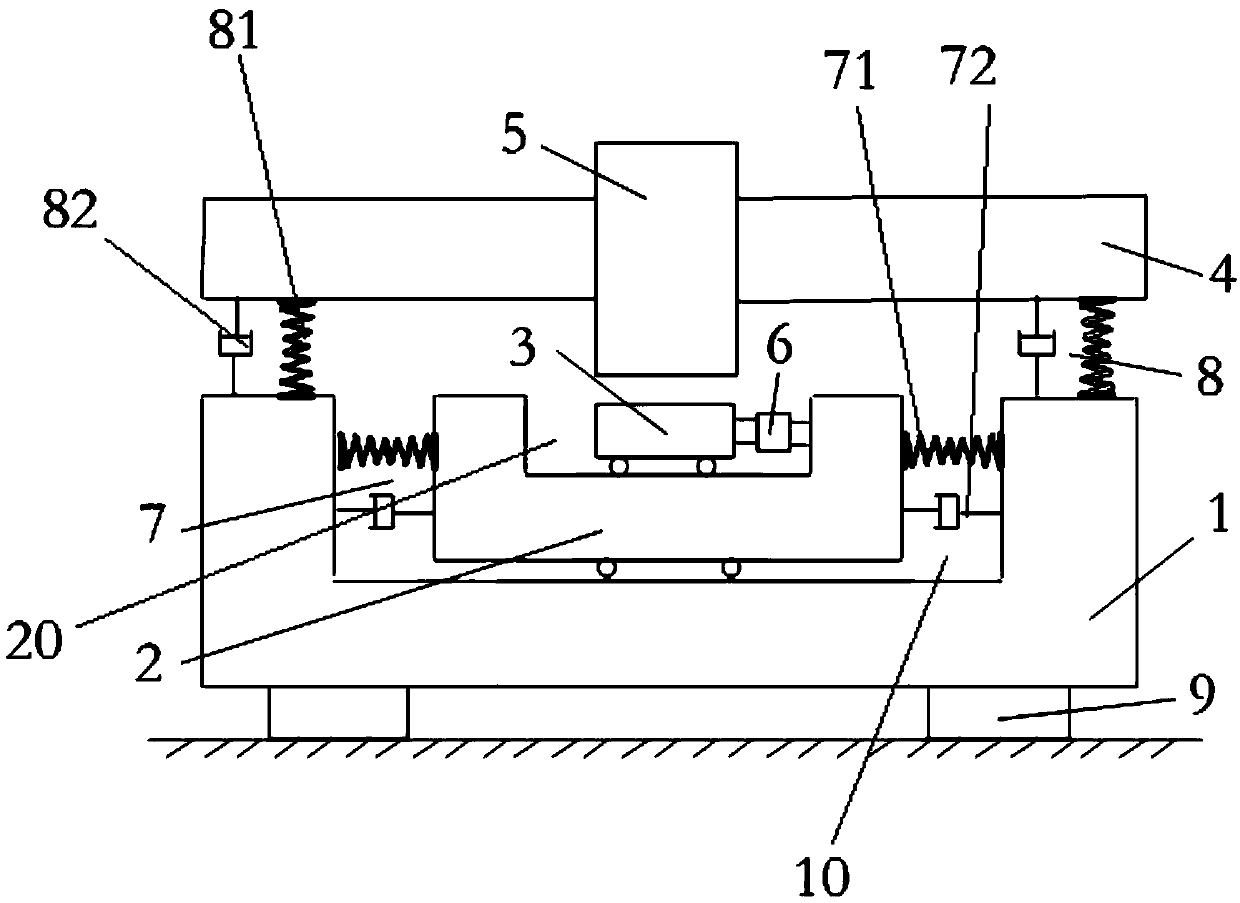

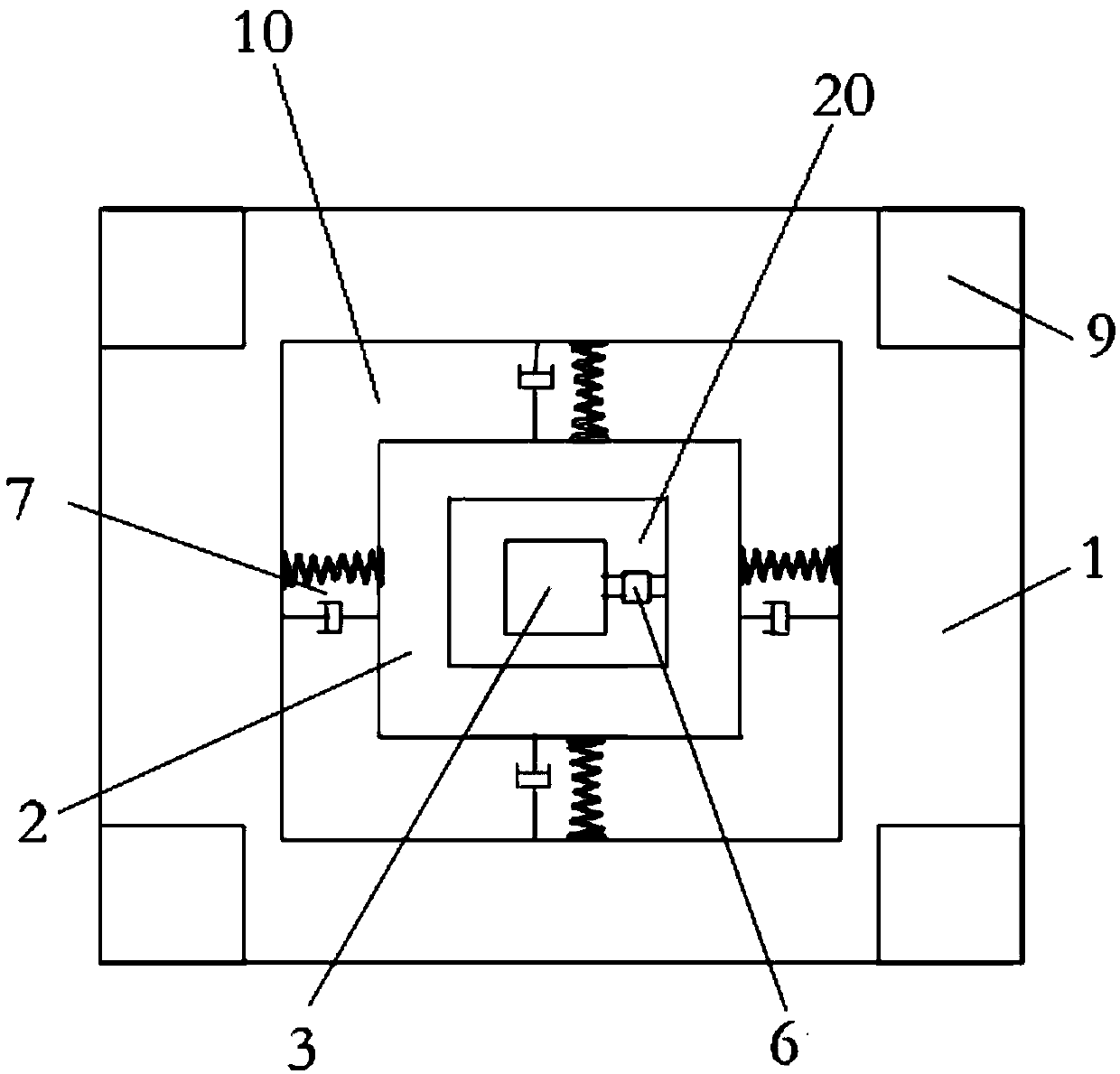

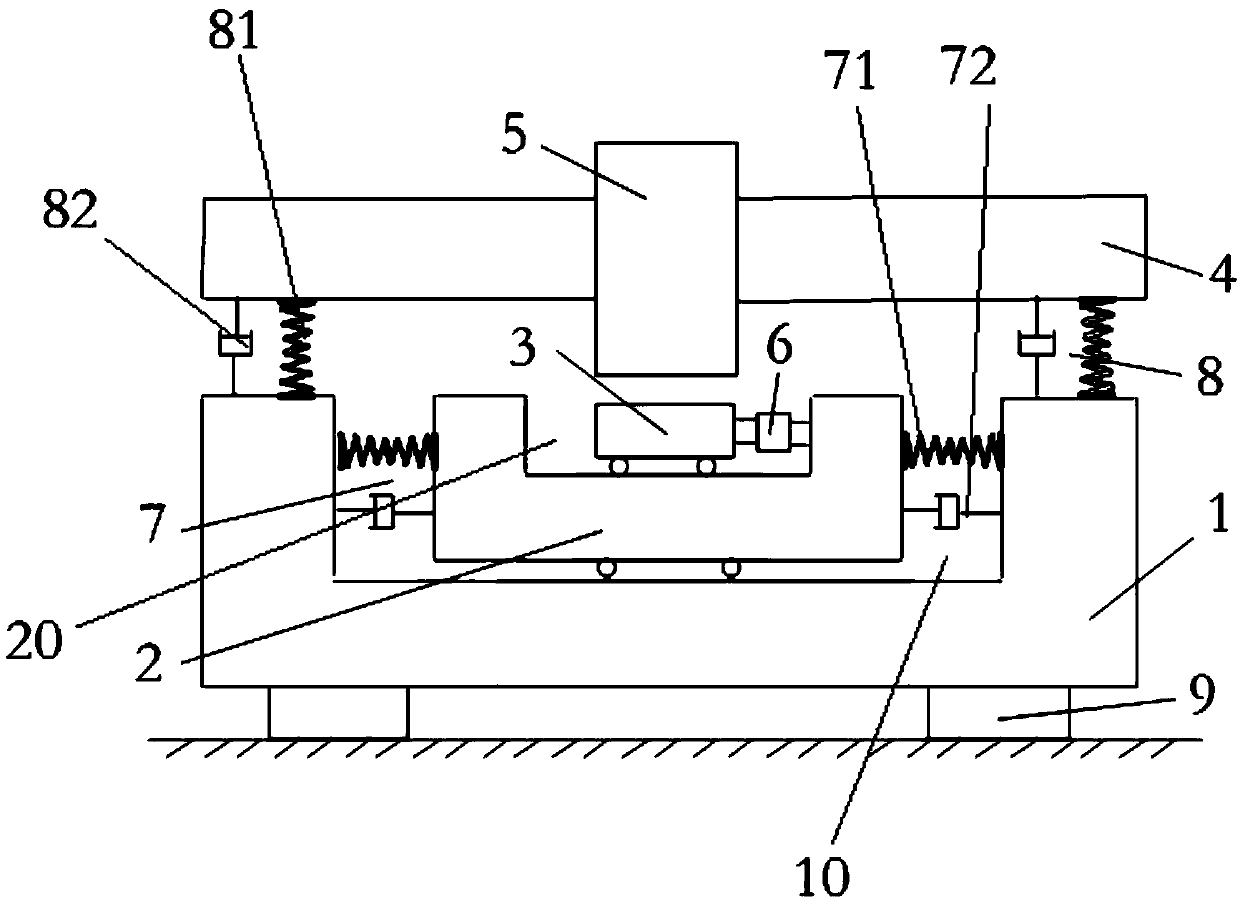

[0022] A gene sequencer provided in this embodiment, such as figure 1 and figure 2 As shown, including a base 1 with a flat bottom, a cavity 10 opening upwards is formed on the upper surface of the base 1, a vibration-absorbing block 2 is arranged at the center of the cavity 10, and a workpiece table 3 is fixed above the vibration-absorbing block 2. 1 is also fixed with a fixed frame 4, and the center of the fixed frame 4 is fixed with an optical imaging device 5, and the optical imaging device 5 is used to collect and identify the fluorescent signal emitted by the workpiece table 3. The surface of the vibration-absorbing block 2 is formed with an active area 20 for the movement of the workpiece table 3 . The active area 20 is in a semi-enclosed structure with an open top facing the optical imaging device 5 . The movable area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com