Optical Fiber Panel and Its Debugging Method

A technology of optical fiber panel and debugging method, which is applied in the direction of bundled optical fibers, etc., can solve the problems that optical fibers cannot transmit optical fibers, low light transmittance, and poor image resolution, so as to avoid low image resolution and high image contrast. The effect of stable performance and interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background art that the optical fiber panel in the prior art has the problems of low light transmittance and low image resolution.

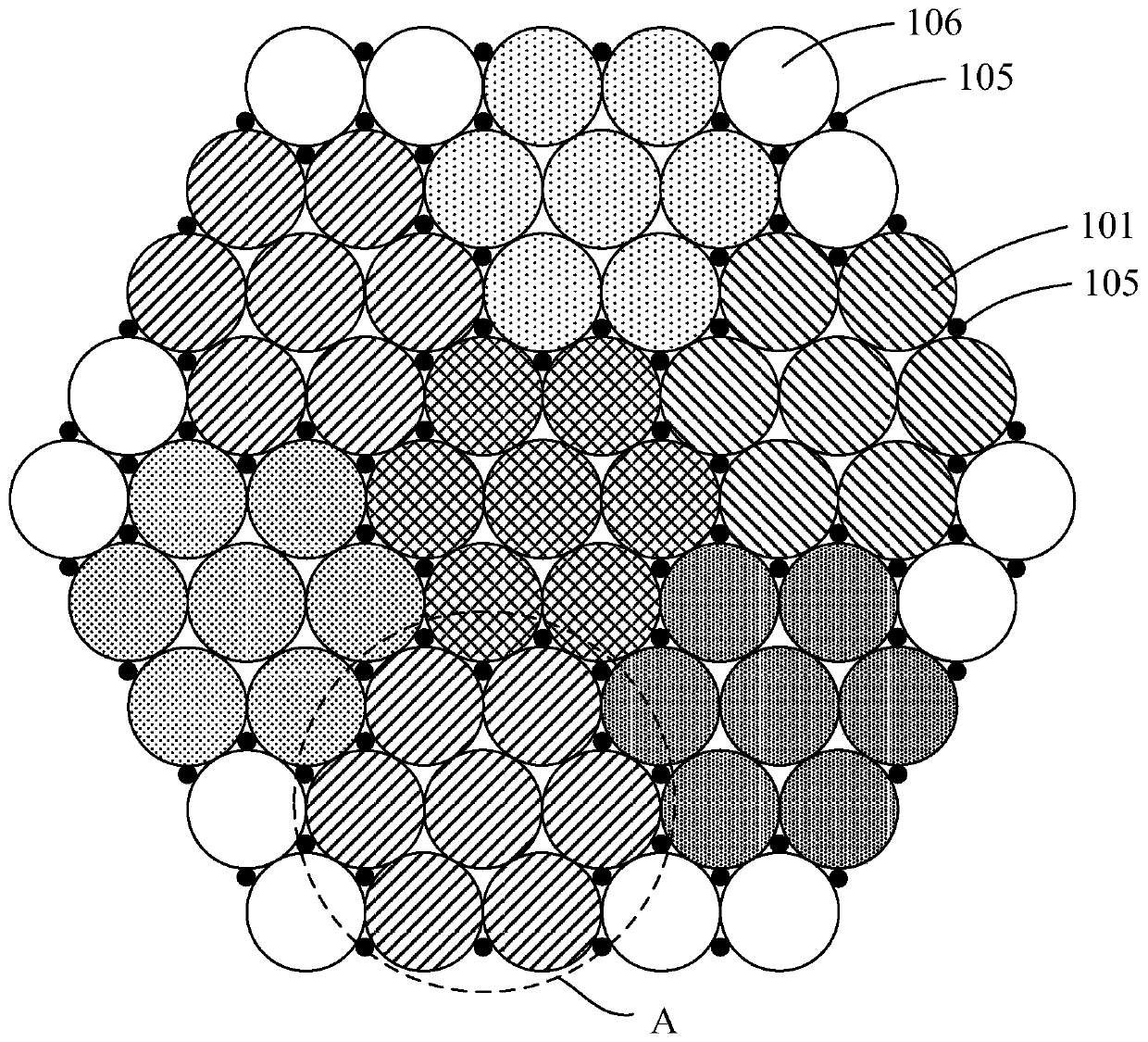

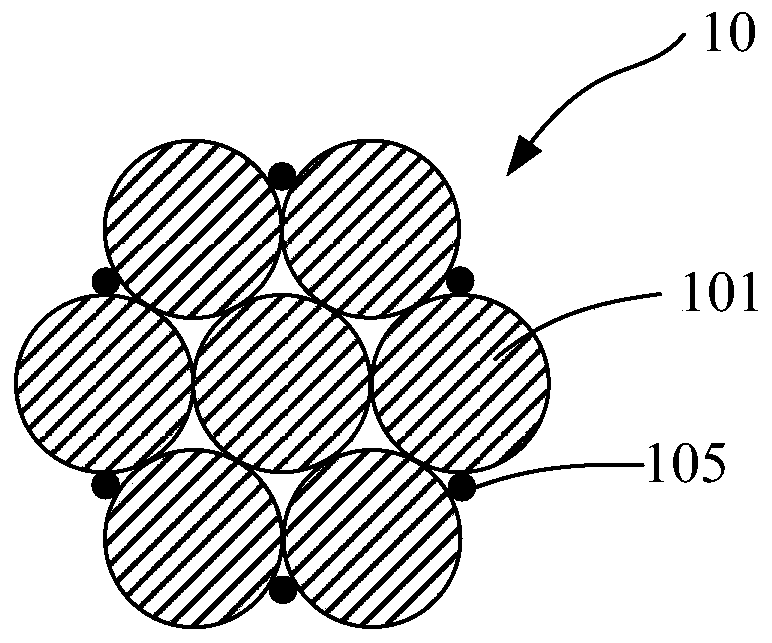

[0030] The method of inserting wires can solve the above problems to a certain extent, but the conventional solution of inserting wires leads to a decrease in the light transmittance of the fiber optic panel. Specifically, a gap is formed between the three optical fibers, and the gap is filled with a filament with a diameter about 0.14 times the diameter of the optical fiber, and the filled filament has the function of absorbing light, and the filament is called an absorbing filament; The technical solution for inserting the filaments is as follows: place absorbing filaments on all six interfaces of the optical fiber; or selectively remove some optical fiber filaments and replace them with absorbing filaments.

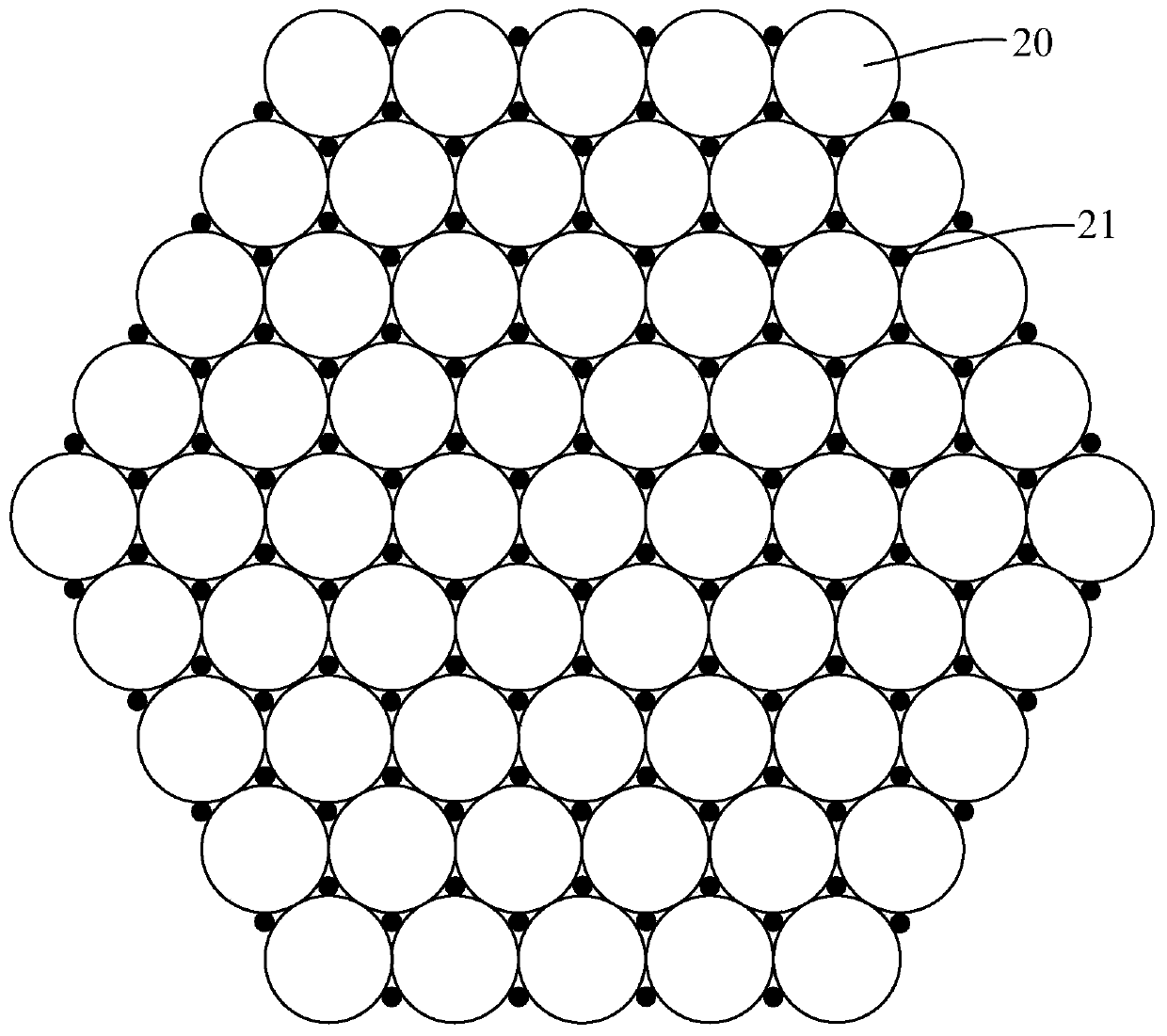

[0031] Such as figure 1 as shown, figure 1 It is a schematic cross-sectional structure diagram of an op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com