Synchronous motor double-layer rotor structure

A rotor structure, synchronous motor technology, applied in the magnetic circuit shape/style/structure, electric components, electrical components, etc., can solve the problems of low utilization rate of permanent magnet magnetic circuit, poor heat dissipation capacity of permanent magnet, etc., to improve the output torque , Improve the magnetic utilization rate, improve the effect of heat dissipation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

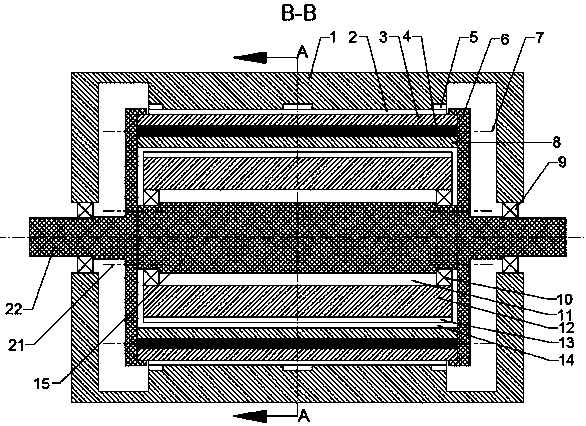

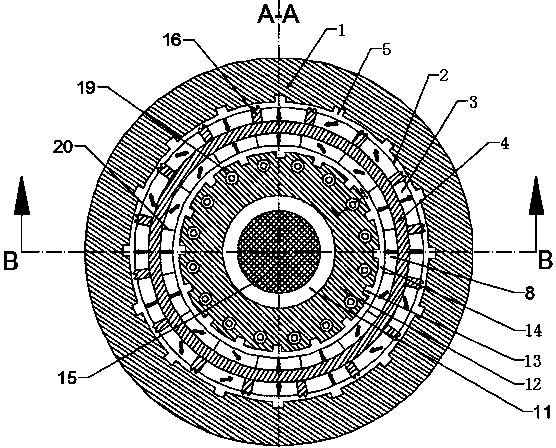

[0017] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same symbols. For the sake of clarity, various parts in the drawings have not been drawn to scale.

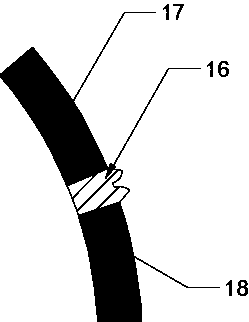

[0018] Such as figure 1 , 2 As shown, the synchronous motor double-layer rotor structure provided by the present invention includes an inner stator (12), an outer stator (1), and a double-layer rotor. The double-layer rotor includes an inner permanent magnet (8), an outer permanent magnet (3), a magnetic isolation material (4), and a wedge-shaped magnetic permeable structure (16). The double-layer rotor is installed between the inner stator (12) and the outer stator (1). The inner permanent magnets (8) and outer permanent magnets (3) of the double-layer rotor are installed with Halbach permanent magnet arrays. The inner and outer permanent magnets are Between the magnets is a magnetic se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com