Three-phase separation stator yoke-free modularized axial magnetic flux permanent magnet disc type wheel hub direct-driven motor

A wheel-hub direct-drive motor, three-phase separation technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit, etc., to reduce space occupation, improve efficiency, reduce The effect of surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

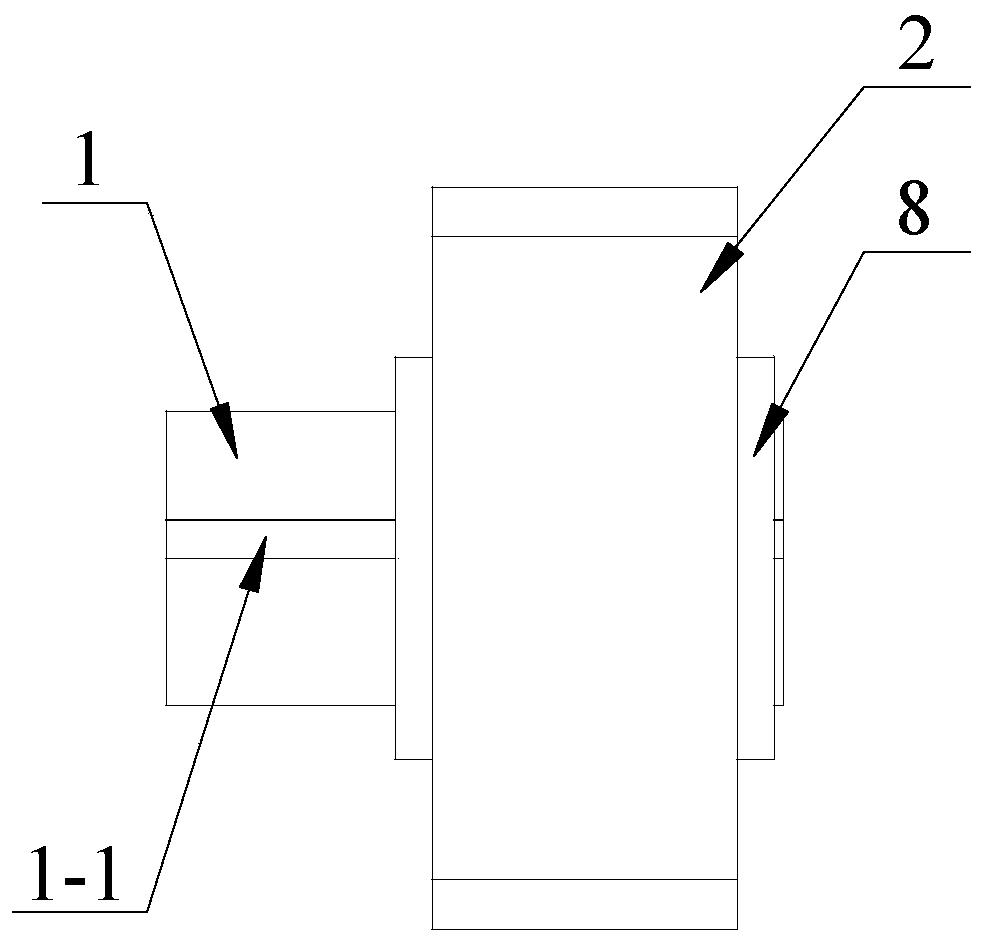

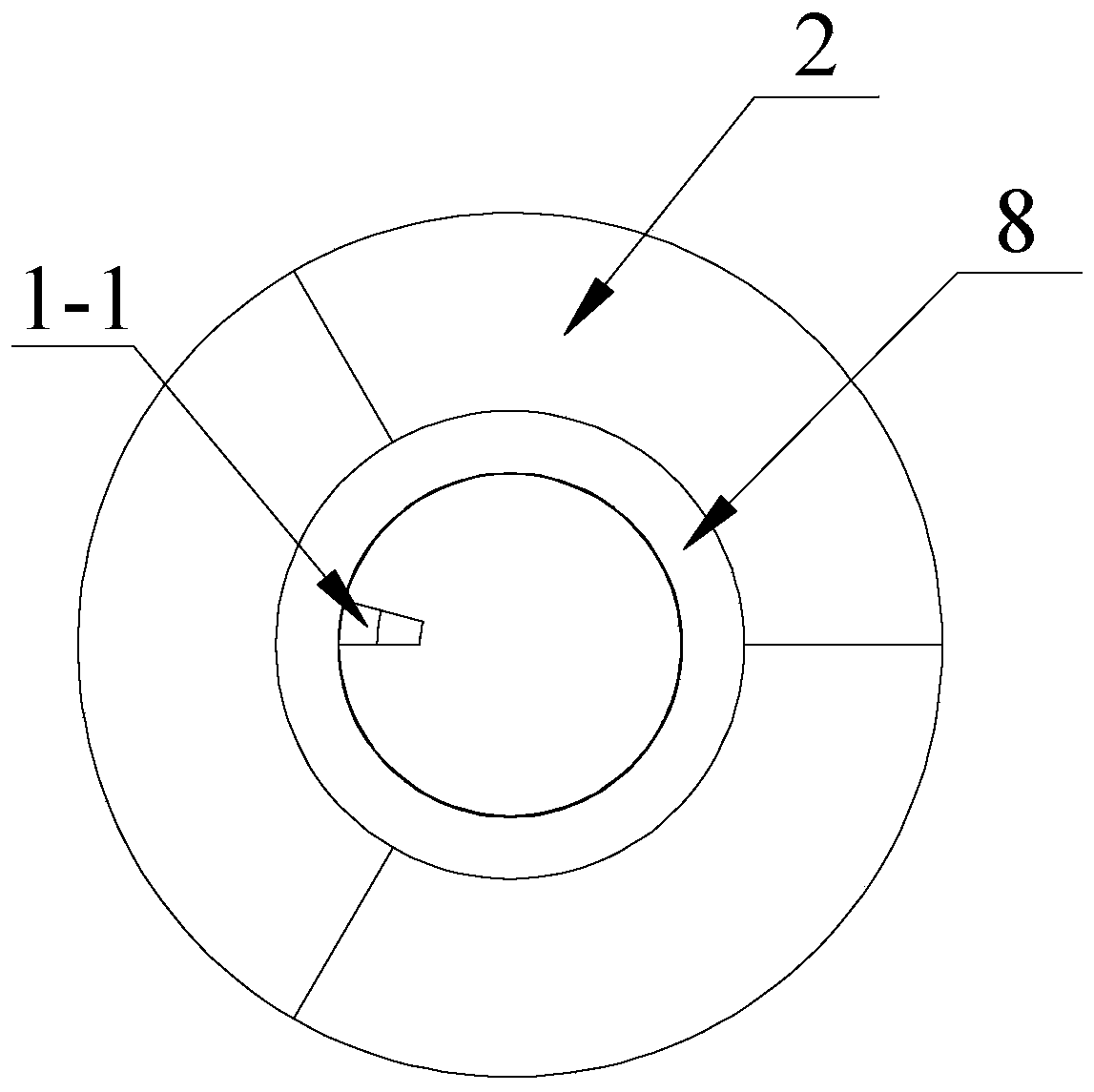

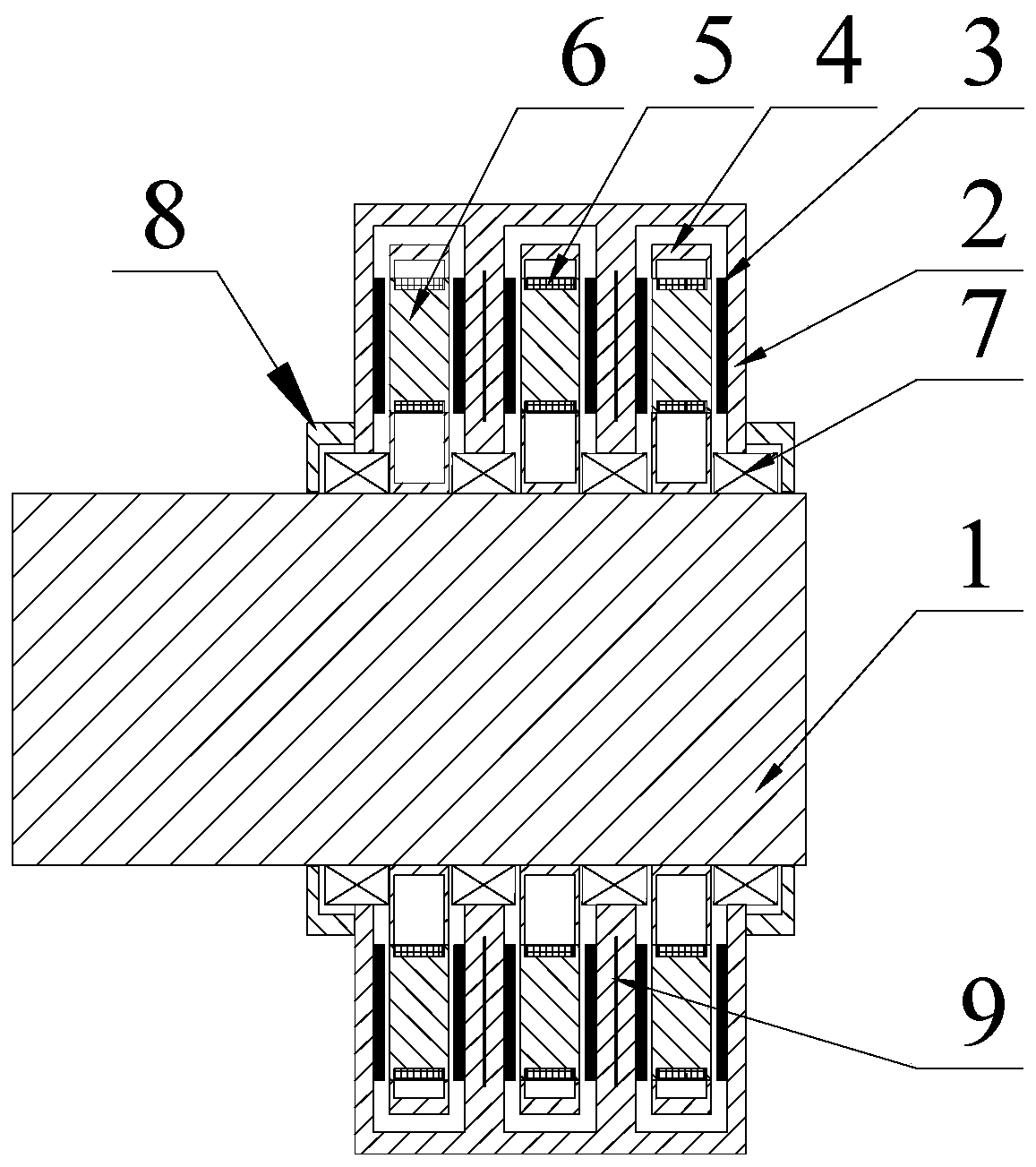

[0029] see Figure 1 to Figure 11 , the three-phase separated stator yokeless modular axial flux permanent disk hub direct drive motor in this embodiment includes an outer rotor, an inner stator and a fixed shaft 1, the inner stator is fixedly arranged on the fixed shaft 1, and the inner stator is arranged on the outer The inside of the rotor, and there is an air gap between the two, and the rotation connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com