Liquid detergent composition

A technology for liquid detergents and compositions, applied in the directions of detergent compositions, surface active detergent compositions, detergent compounding agents, etc., can solve problems such as difficulty in removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

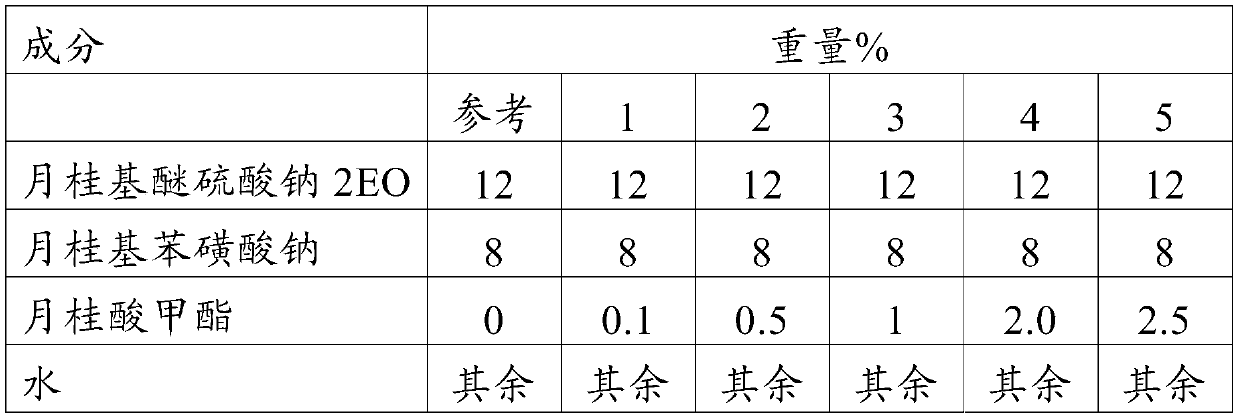

[0095] Liquid detergent compositions were prepared based on the formulations shown in Table 1.

[0096] Table 1

[0097]

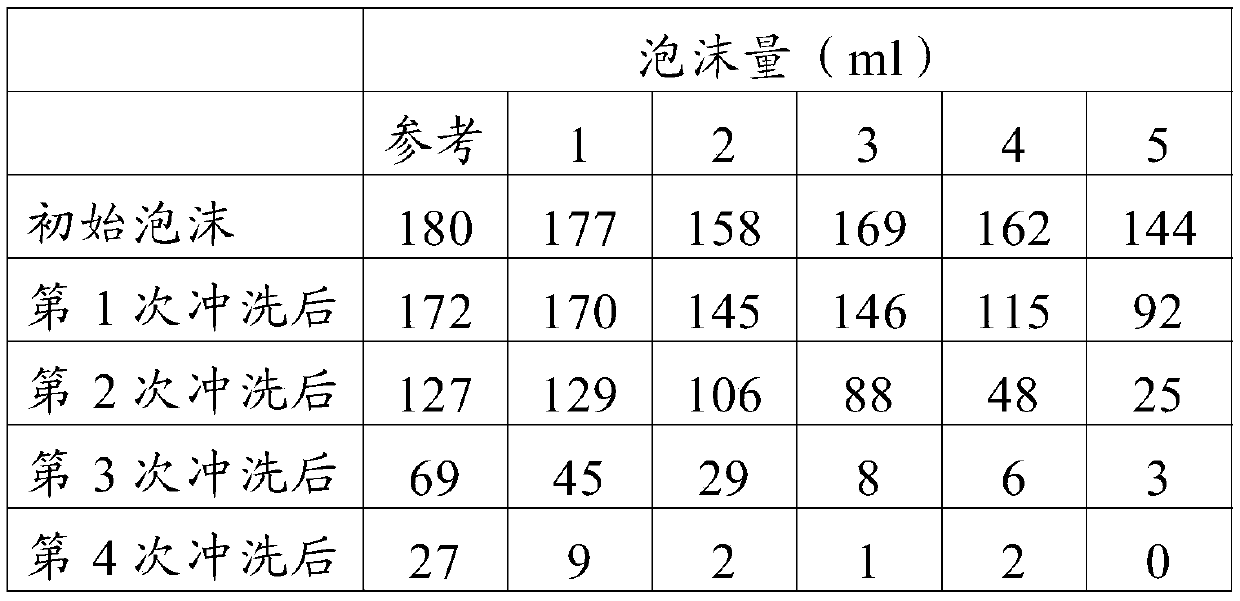

[0098] The foaming behavior of these liquid detergent compositions, including foam rinseability, was evaluated using the following procedure:

[0099] 1. Dilute 6.25 grams of liquid detergent composition with water to make 1 liter of cleaning solution.

[0100] 2. Introduce 50ml of cleaning solution into a 250ml graduated cylinder, shake the cylinder ten times.

[0101] 3. Carefully decant the liquid and measure the foam volume.

[0102] 4. Introduce 50ml of fresh water into the graduated cylinder to simulate a rinse and shake the graduated cylinder again.

[0103] 5. Repeat step 4 until the foam volume is less than or equal to 2ml.

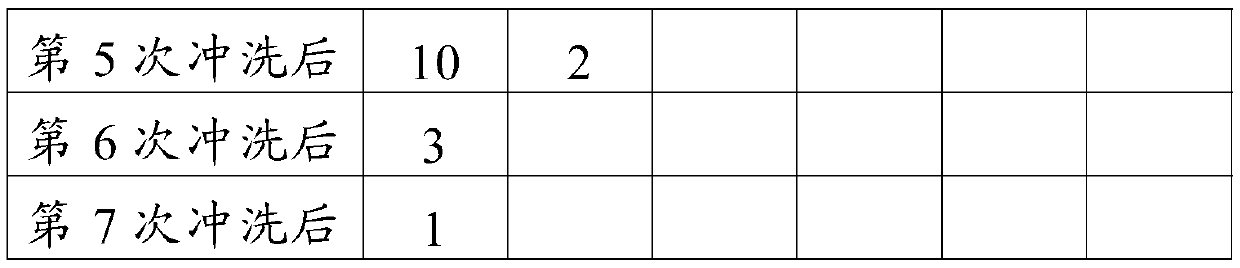

[0104] The evaluation results are summarized in Table 2.

[0105] Table 2

[0106]

[0107]

Embodiment 2

[0109] Liquid detergent compositions were prepared based on the formulations shown in Table 3.

[0110] table 3

[0111]

[0112] The foaming behavior of these liquid detergent compositions, including foam rinseability, was evaluated using the method described in Example 1.

[0113] The evaluation results are summarized in Table 4.

[0114] Table 4

[0115]

[0116]

Embodiment 3

[0118] Liquid detergent formulations were prepared based on the formulations shown in Table 5. Formulation B is based on Example 2 in Table 1 of WO2006 / 081944.

[0119] table 5

[0120]

[0121] The foaming behavior of these liquid detergent compositions, including foam rinseability, was evaluated using the method described in Example 1.

[0122] The evaluation results are summarized in Table 6.

[0123] Table 6

[0124]

[0125]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com