Discrete beam method for motion planning of welding robot

A technology of robot motion and motion planning, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., and can solve problems such as optimization and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

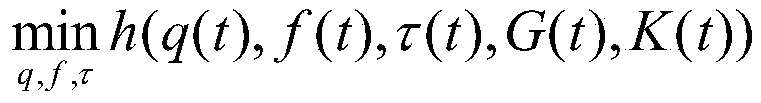

[0072] A discrete beam method for motion planning of a welding robot, the discrete beam method solves the problem of robot motion planning, and the welding robot is defined as a tree-shaped welding robot in which some rigid bodies are assembled by joints, that is, the main body is a node and the joint is an edge; The motion planning model includes a displacement control variable q(t), which is called configuration, and the parameter vector of the joint is the control variable of the motion planning model, q(t) is abbreviated as q, and the admissible function q needs to satisfy The following equation of motion EoM has physical meaning:

[0073]

[0074] Among them, the subscript r represents the welding robot, the subscript j represents the joint, and M r Indicates the inertia of the welding robot, B r Indicates the influence factor brought by the gravity and speed of the welding robot, M j Indicates the inertia of the joint, B j Indicates the influence factor brought by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com