A Subgradient Method for Welding Robot Motion Model

A welding robot and robot movement technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problem of fewer algorithms and achieve the effects of small time-consuming, simple algorithm structure, and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

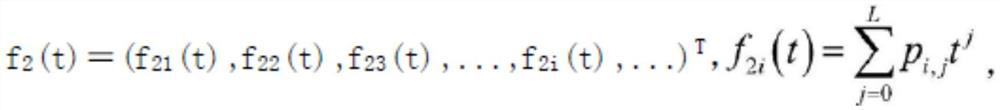

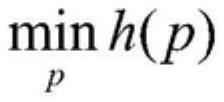

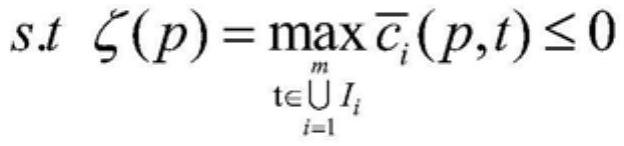

[0063] The present invention is a sub-gradient method of a motion model of a welding robot. The sub-gradient method is a non-smooth optimization method proposed based on the problem of a non-smooth motion planning model of a welding robot. The problem of a non-smooth motion planning model of a welding robot is a motion planning problem. After mutating the motion planning problem, the non-smooth motion planning model of the welding robot is obtained.

[0064] First review the welding robot motion planning problem:

[0065] The welding robot is defined as a tree-shaped welding robot with some rigid bodies assembled by joints, that is, the main body is a node, and the joint is used as an edge; the motion planning model includes a displacement control variable q(t), which is called a configuration, and the The parameter vector of the joint is the control variable of the motion planning model, and q(t) is abbreviated as q. The allowable function q needs to satisfy the following equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com