Safe and stable scissor jack and using method thereof

A jack and stable technology, applied in the direction of lifting device, etc., can solve the problems of difficult to guarantee safety, casualty parts, jack rollover, etc., to avoid safety accidents, the overall structure is simple, and the integrity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

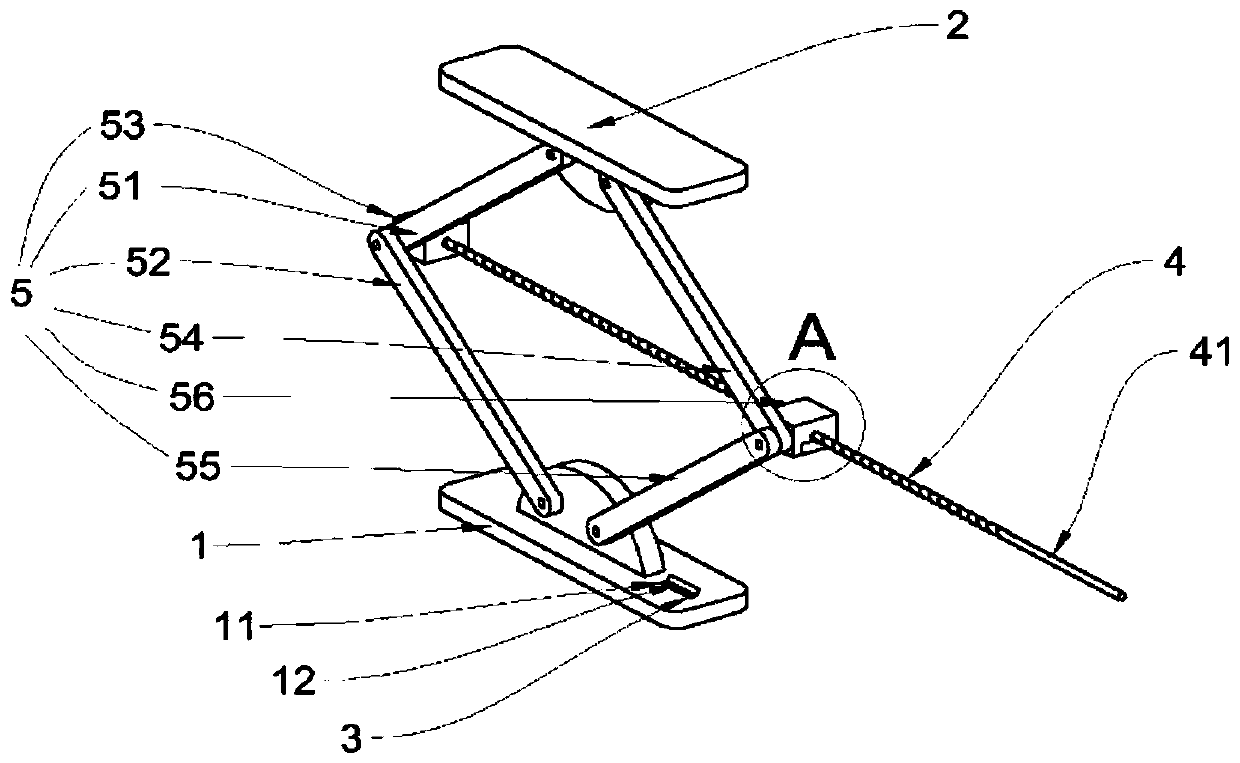

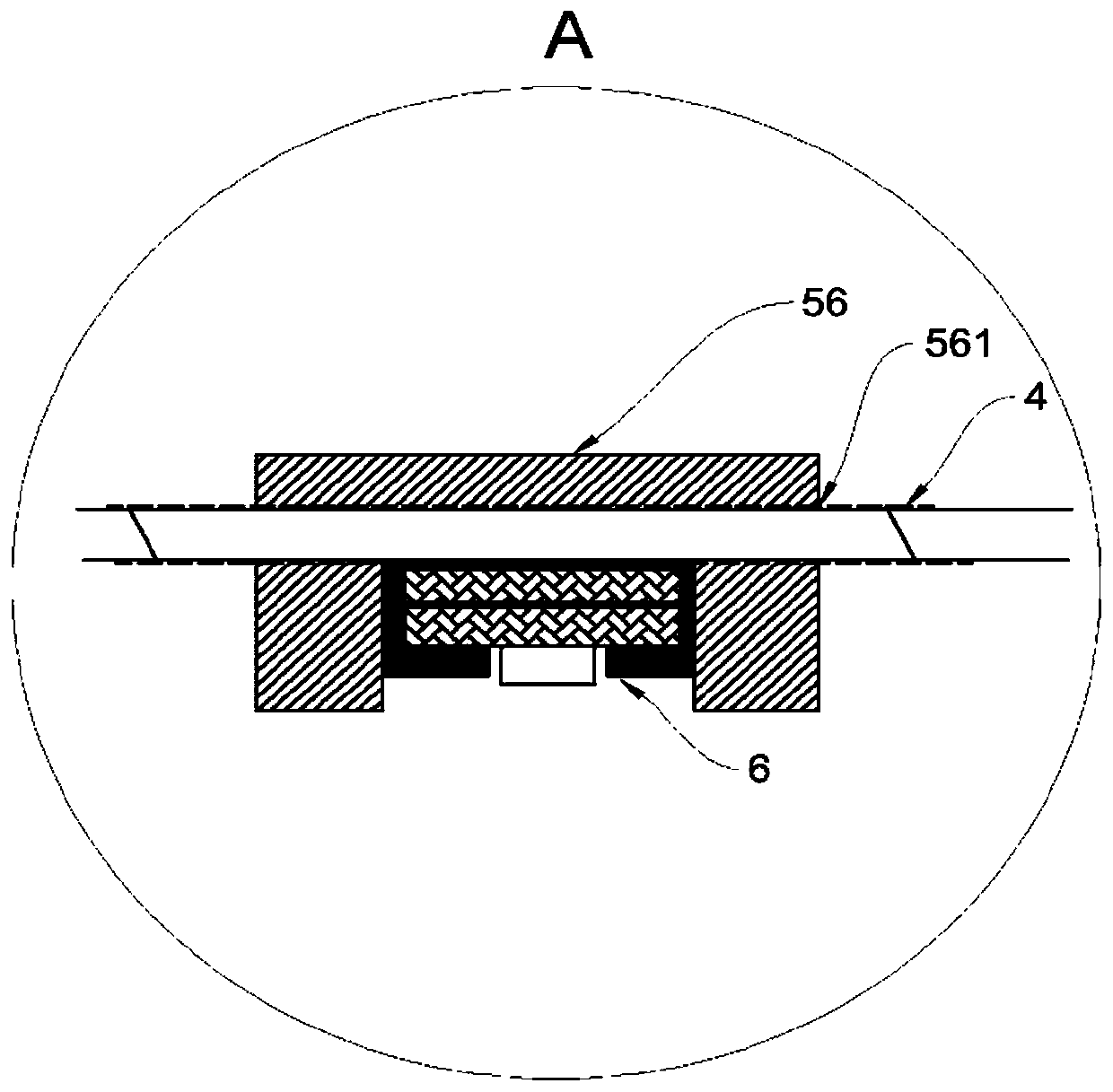

[0033] Such as figure 1 , figure 2 As shown, a safe and stable scissor jack includes a base 1, a top plate 2, a support assembly 5, a handle 3 and a threaded screw 4; the support assembly 5 includes a left upper support rod 51, a left lower support rod 52, an upper right Support rod 54, right lower support rod 55, left connecting block 53, right connecting block 56; the first end of each upper supporting rod is rotatably connected with the top plate 2, the second end is rotatably connected with the connecting block of the corresponding orientation, and each lower support The first end of the rod is rotatably connected to the base 1, and the second end is rotatably connected to the connecting block of the corresponding orientation; the right connecting block 56 is provided with a through threaded hole 561, and the first end of the threaded screw rod 4 is connected to the left connecting block 53 is fixedly connected, and the second end passes through the threaded hole 561 and...

Embodiment 2

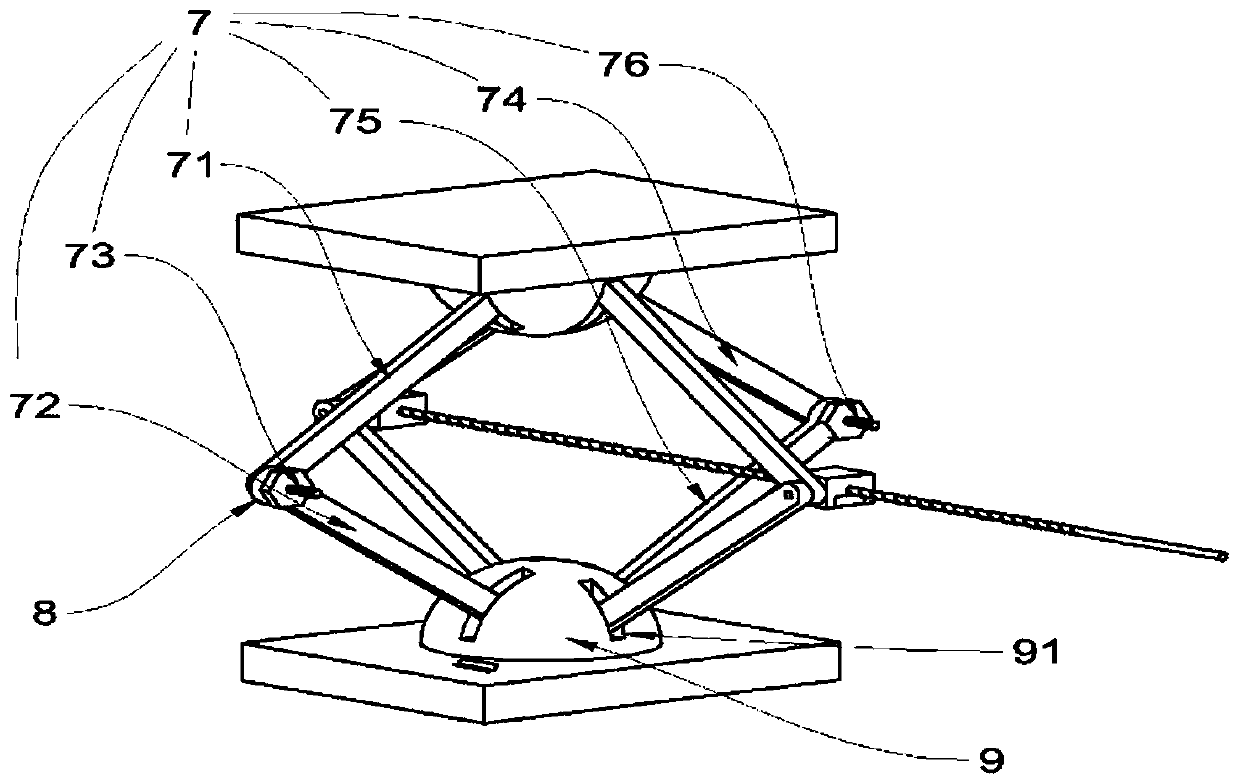

[0036] Such as image 3 As shown: this embodiment has been further deepened on the basis of embodiment 1, and its main improvement is that the above-mentioned scissor jack also includes a stabilizing assembly 7, and the stabilizing assembly 7 includes a front upper support rod 71 and a front lower support rod 72 , rear upper support rod 74, rear lower support rod 75, front connecting bolt 73, rear connecting bolt 76; the bottom of the screw rod of the front and rear connecting bolts 73,76 is a smooth part; the front upper supporting rod 71, rear upper supporting rod 74 The first end is rotatably connected to the top plate 2, and the second end is rotatably connected to the smooth part of the corresponding connecting bolt; the first end of the front lower support rod 72 and the rear lower support rod 75 are rotatably connected to the base 1, and the second end is rotatably connected. Connect to the smooth part of the corresponding connecting bolt. In the jack of this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com