Electric moving trolley used for steering test table

A technology of steering test and mobile trolley, which is applied in the direction of hoisting device, lifting frame, manual conveying device, etc., which can solve the problems of difficult lifting height precision control, labor-intensive, and low practicability, and achieve manpower saving, convenient operation, and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

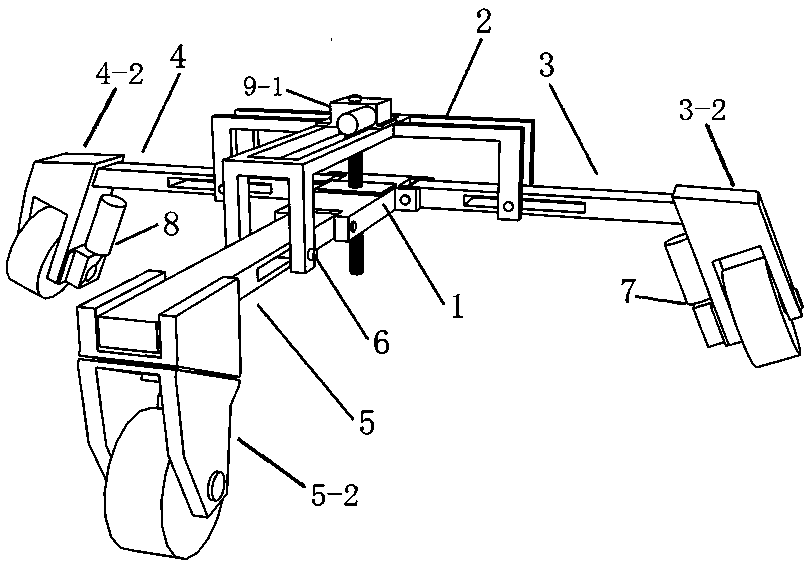

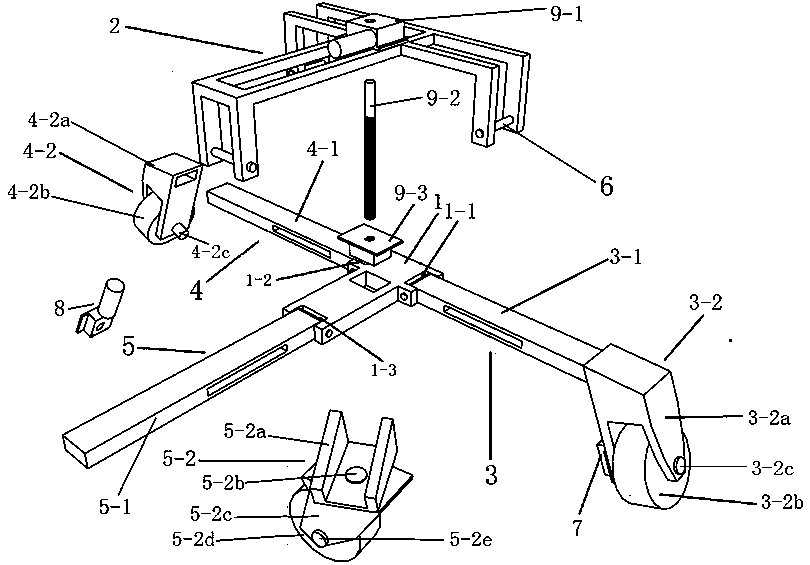

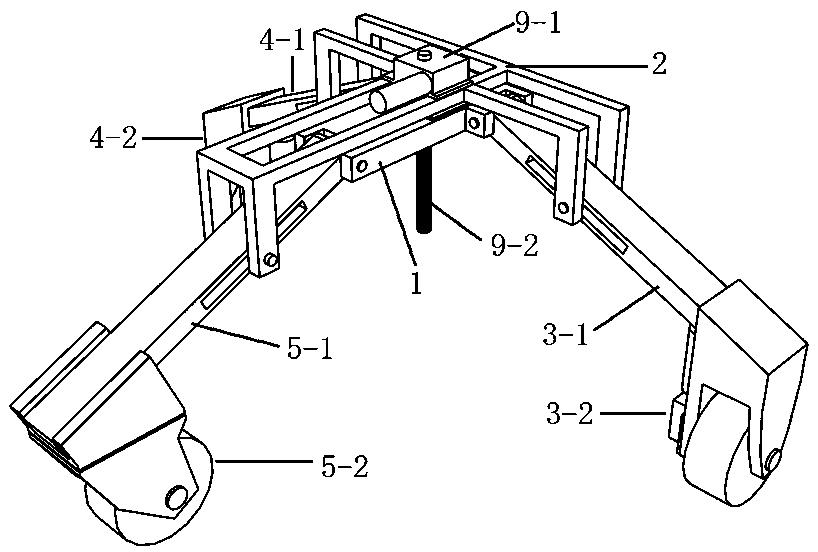

[0039] Embodiment one: if Figure 3-7 As shown, when the test table hollowed out at the bottom needs to be moved, the drive controller remotely controls the lifting hollow shaft reduction motor 9-1 to drive the lifting screw 9-2 to rotate forward, and the lifting screw 9-2 drives the lifting nut 9-3 through the screw. , so that the lifting platform 1 makes a downward movement along the lifting screw 9-2, and drives the left bracket 3-1, the right bracket 4-1 and the front bracket 5-1 to move around the pin 6 on the three claws of the lifting adjustment bracket 2 to seesaw respectively , and then drive the left drive wheel 3-2, the right drive wheel 4-2 and the front universal wheel 5-2 to rise synchronously, and when the three wheels rise to the bottom of the test table, the drive controller controls the lifting screw 9 -2 Stop the rotation, and control the left hollow shaft deceleration motor 7 and the right hollow shaft deceleration motor 8 to respectively drive the left dri...

Embodiment 2

[0040] Embodiment two: if Figure 5-7 As shown, the electric mobile trolley for the above-mentioned steerable test table is fixed on the bottom surface of the existing test table through the lifting adjustment bracket 2, and can be used as a table leg. When the test table needs to be moved, the upgraded version of the test table can be controlled by driving The driver drives the mobile trolley to move in all directions and shift. When it does not need to move, the drive controller can drive the left drive wheel 3-2, the right drive wheel 4-2 and the front universal wheel 5-2 to rise synchronously and store them at the bottom of the table. Easy to operate and save manpower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com