Slow baking and burning test system of solid rocket engine

A solid rocket and test system technology, applied in the field of solid rocket motor slow burning test system, can solve the problems of low vulnerability and insensitivity, and achieve the effect of wide adjustment range of heating rate and good uniformity of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

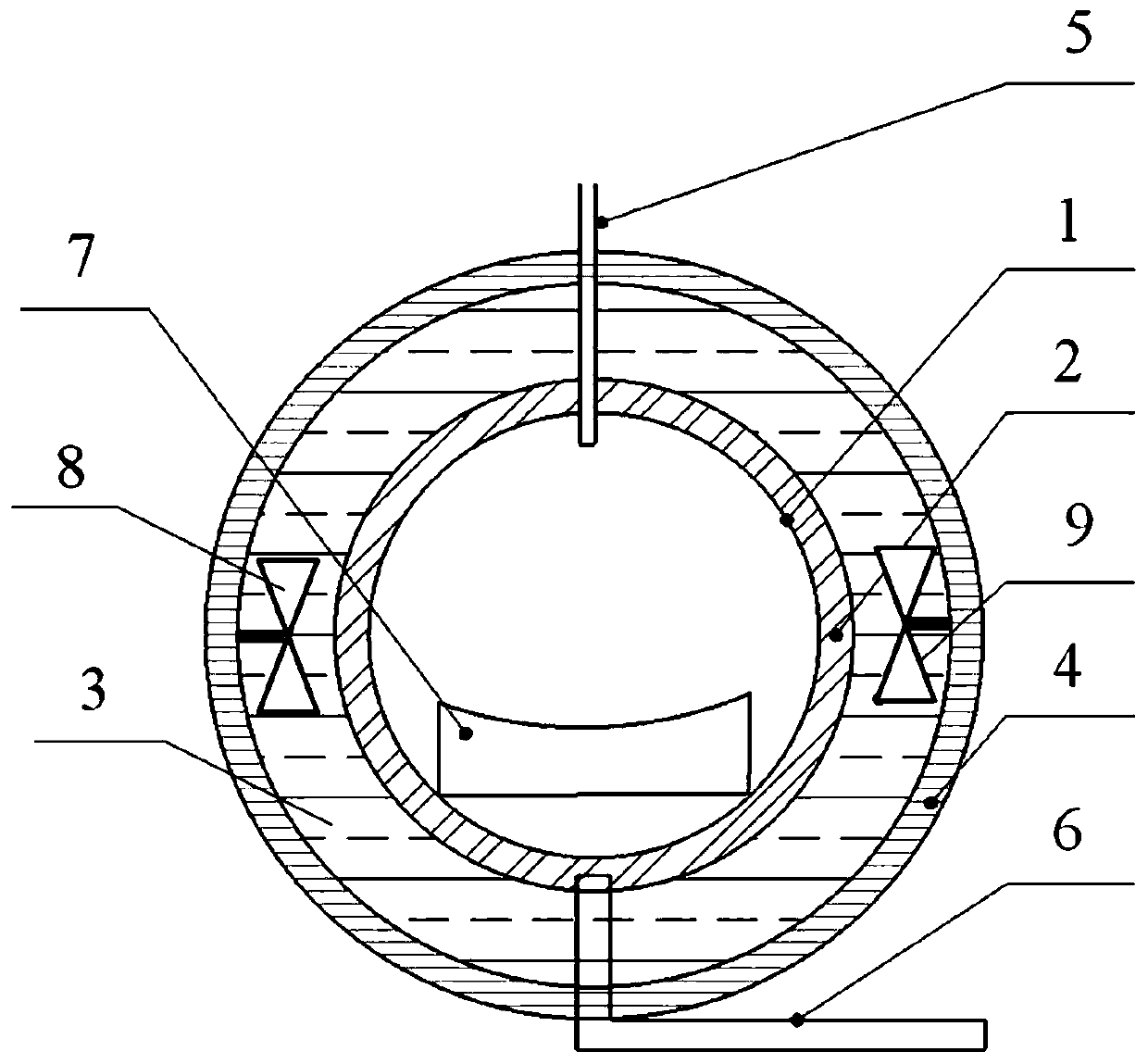

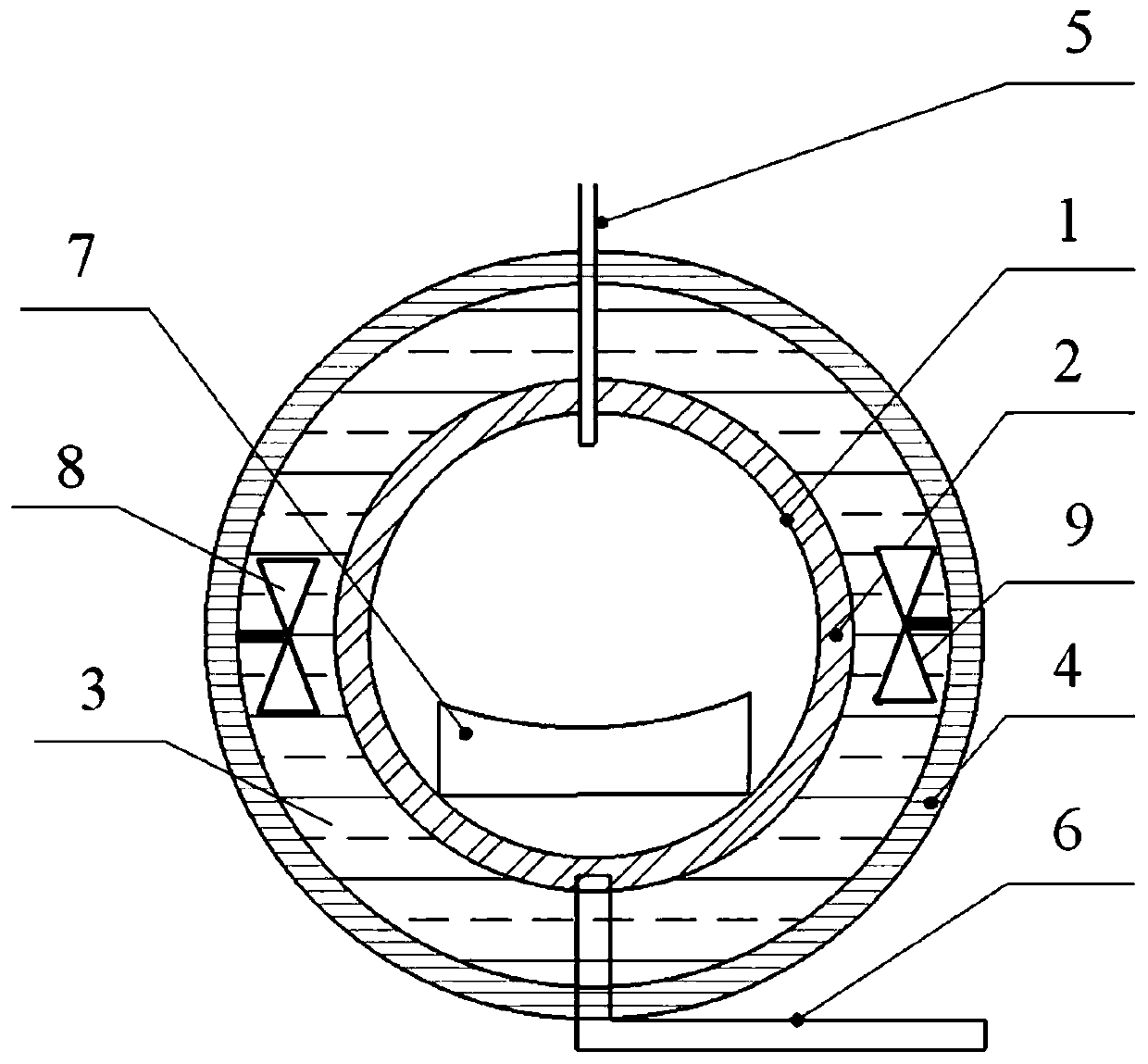

[0027] see figure 1 , a solid rocket motor slow cook-off test system of the present invention, comprising a test chamber 1, a heating system 2, a control system, a data acquisition system, a video monitoring system, a shock wave overpressure sensor and a result discrimination system;

[0028] The test box includes two semi-cylindrical bodies, the two semi-cylindrical bodies are connected into a cylindrical body by buckles, the test box is provided with a sample support 7, and the top of the test box is inserted into a thermocouple 5, The thermocouple is connected with the data acquisition system through a signal line;

[0029] The heating system is wound on the outside of the test box, the heating system is connected to the control system through a control cable 6, the outside of the heating system is wrapped with thermal insulation cotton 3, and a protective shell is arranged on the outside of the thermal insulation cotton 4;

[0030] The control system adopts PID adjustmen...

Embodiment 2

[0042] The present invention will be described in further detail below taking the tactical engine of φ 315mm * 2100mm as an example, but the present invention is not limited to this example.

[0043] First, open the test chamber and insert the thermocouple into the top of the test chamber to the designed depth. Wrap the heating system with ceramic insulating blocks around the test chamber and fix it, and wrap the pre-made insulation cotton evenly on the surface of the heating system.

[0044] Secondly, connect the signal line and the heating system control cable, and remotely check whether the signal and heating system are normal through the control system. After checking the normality, place the tactical engine on the wooden support in the test box and fix it firmly with metal straps. Close the chamber and close the snap.

[0045] Furthermore, set a heating rate of 3.3°C / h, set the end temperature to 300°C, press the start button, and the data acquisition system, heating sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap