Thermal loading device and thermal loading method for variable acceleration environmental test

An environmental test, variable acceleration technology, applied in the direction of temperature control, non-electric variable control, instruments, etc., can solve the problems of maximum temperature, temperature rise rate limit, poor anti-oxidation performance, short circuit of heating wire, etc., to achieve uniform temperature control The effect of good performance, good insulation and high heating index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

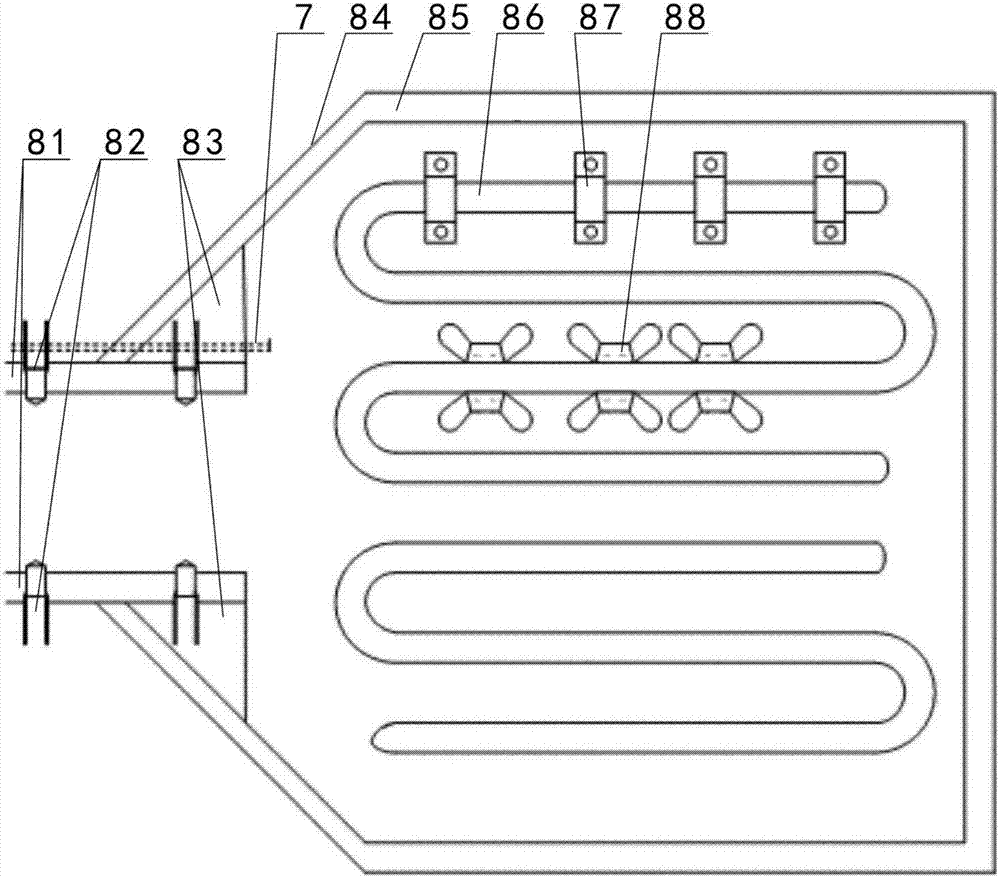

[0018] The present invention will be further explained below in conjunction with the drawings:

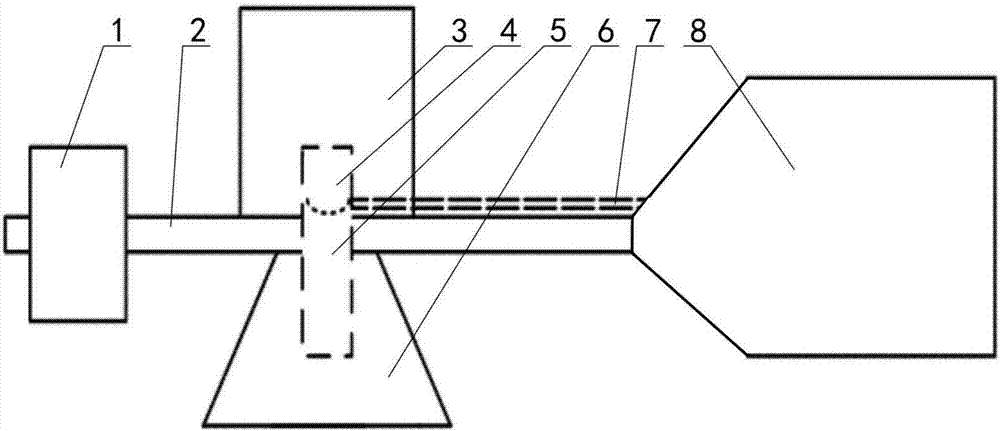

[0019] Such as figure 2 As shown, the thermal loading device for variable acceleration environmental test of the present invention includes a temperature control box (not shown in the figure), a temperature sensor 7, a thermal loading box 84, a heating tube 86, a rotating arm connecting support plate 81, and a corundum heat insulation card Hoop 87 and petal-shaped radiating fin 88, the wall of the heat loading box 84 is a sandwich stainless steel plate, the sandwich of the sandwich stainless steel plate is filled with insulation wool 85, the heating tube 86 is two independent sections, each section of heating tube 86 is horizontally installed in the heat loading box 84, the sensing end of the temperature sensor 7 is placed in the heat loading box 84, the signal output end of the temperature sensor 7 and the input ends of the two sections of heating pipe 86 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com