Container with temperature control function and freeze drying box of freeze dryer

A temperature control and functional technology, applied in the field of freeze-drying boxes, can solve the problems of increased labor intensity and complexity, inability to achieve temperature control uniformity, inconvenient installation and maintenance work, etc., to reduce the possibility of freezing and ice damage, processing The effect of convenient manufacturing and reduced difficulty in welding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

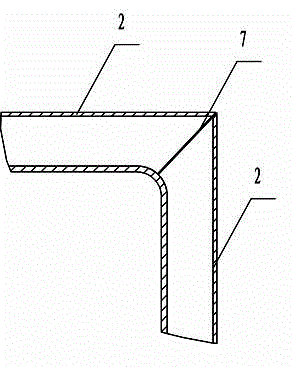

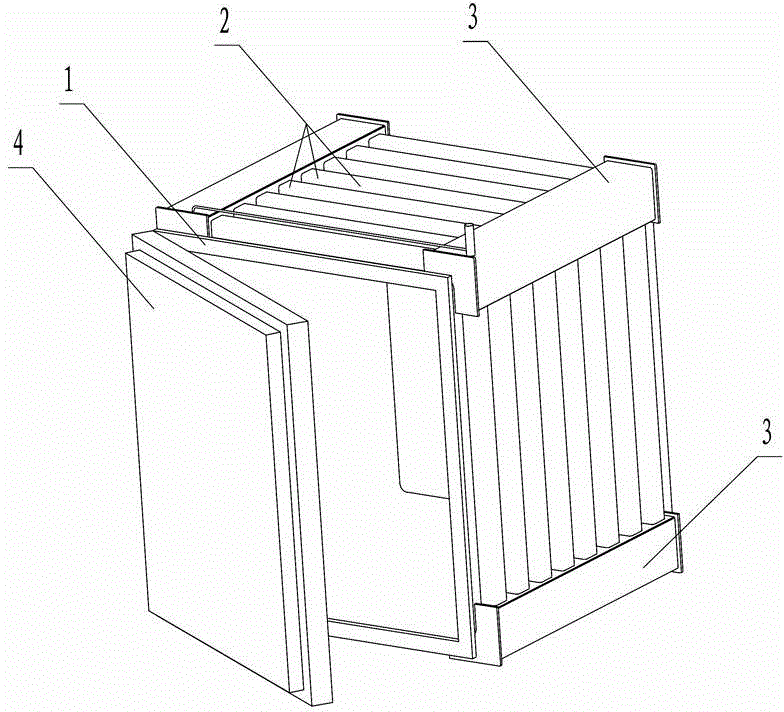

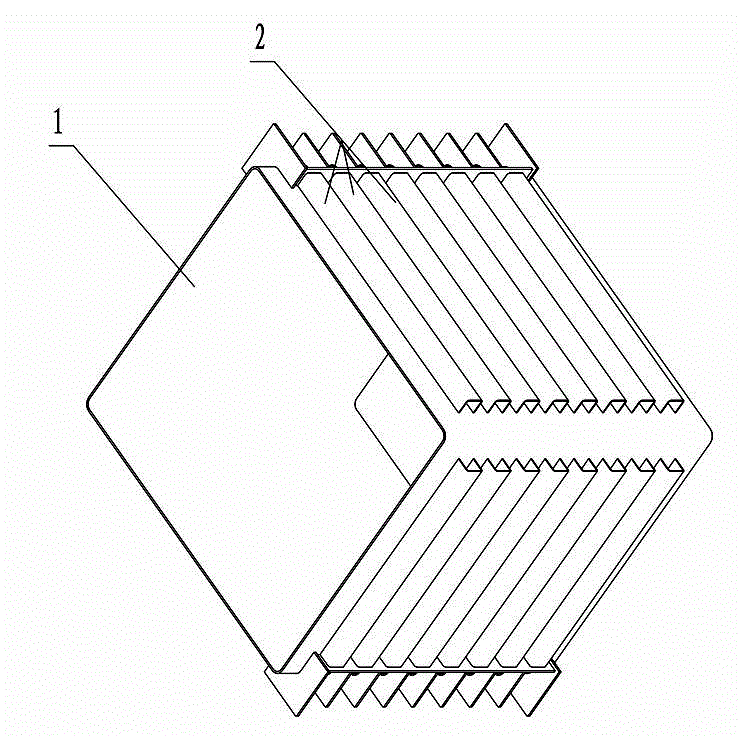

[0029] Such as Figure 2 to Figure 6 As shown, the container with temperature control function of the present invention includes a box body 1 and a temperature control fluid transmission assembly, the box body 1 is provided with a box door 4, and the temperature control fluid transmission assembly includes a More than one turn of the temperature control fluid jacket 2, and a flowing temperature control medium is introduced into the temperature control fluid jacket 2 to control the overall temperature of the box body 1. The temperature control fluid jacket 2 of each circle is divided into more than two sections, and a transition connection part 3 is provided between two adjacent sections of the temperature control fluid jacket 2 of the same circle, and the transition communication of different circles at the corresponding positions on ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap