Hot metal square thermal analysis sample cup special for high-carbon equivalent

A high carbon equivalent, thermal analysis technology, applied in material thermal analysis, analytical materials, measuring devices, etc., can solve problems such as difficulty in finding eutectic temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

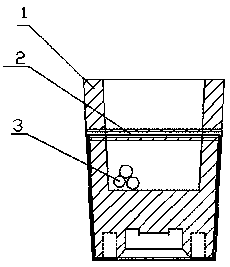

Image

Examples

Embodiment 1

[0015] The chiller 3 is composed of the following components by weight: 7 parts of tellurium, 0.5 parts of aluminum, 0.5 parts of titanium, and 1 part of sulfur. The above components are made into 0.5-1.5 mm particles and uniformly mixed to form the chiller.

Embodiment 2

[0017] The chiller 3 is composed of the following components, by weight, 8 parts of tellurium, 1 part of aluminum, 1 part of titanium, and 2 parts of sulfur. The above-mentioned ingredients are made into 0.5-1.5mm particles and uniformly mixed to form the chiller.

Embodiment 3

[0019] The chiller 3 is composed of the following components, by weight, 7.5 parts of tellurium, 0.8 parts of aluminum, 0.58 parts of titanium, and 1.5 parts of sulfur. The above-mentioned ingredients are made into 0.5-1.5 mm particles and uniformly mixed to form the chiller.

[0020] In the present invention, anti-graphitization materials and oxidized alloy components (ie, the components contained in the chiller 3 in the present invention) are added in the sample cup to be used as a chiller to promote whether the molten iron is hypoeutectic or hypereutectic, Regardless of whether it has been inoculated or not, it can solidify according to the white mouth, and shows a long eutectic stop platform on the cooling curve, so as to obtain accurate CEL, C, and Si values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com