Jump ring type self-locking anti-loose connector

A technology of electrical connectors and circlips, applied in connection, two-part connection devices, parts of connection devices, etc., can solve problems such as complex product structure, increased manufacturing costs, and loose locking, and achieve consistent performance of parts Good, extended service life, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

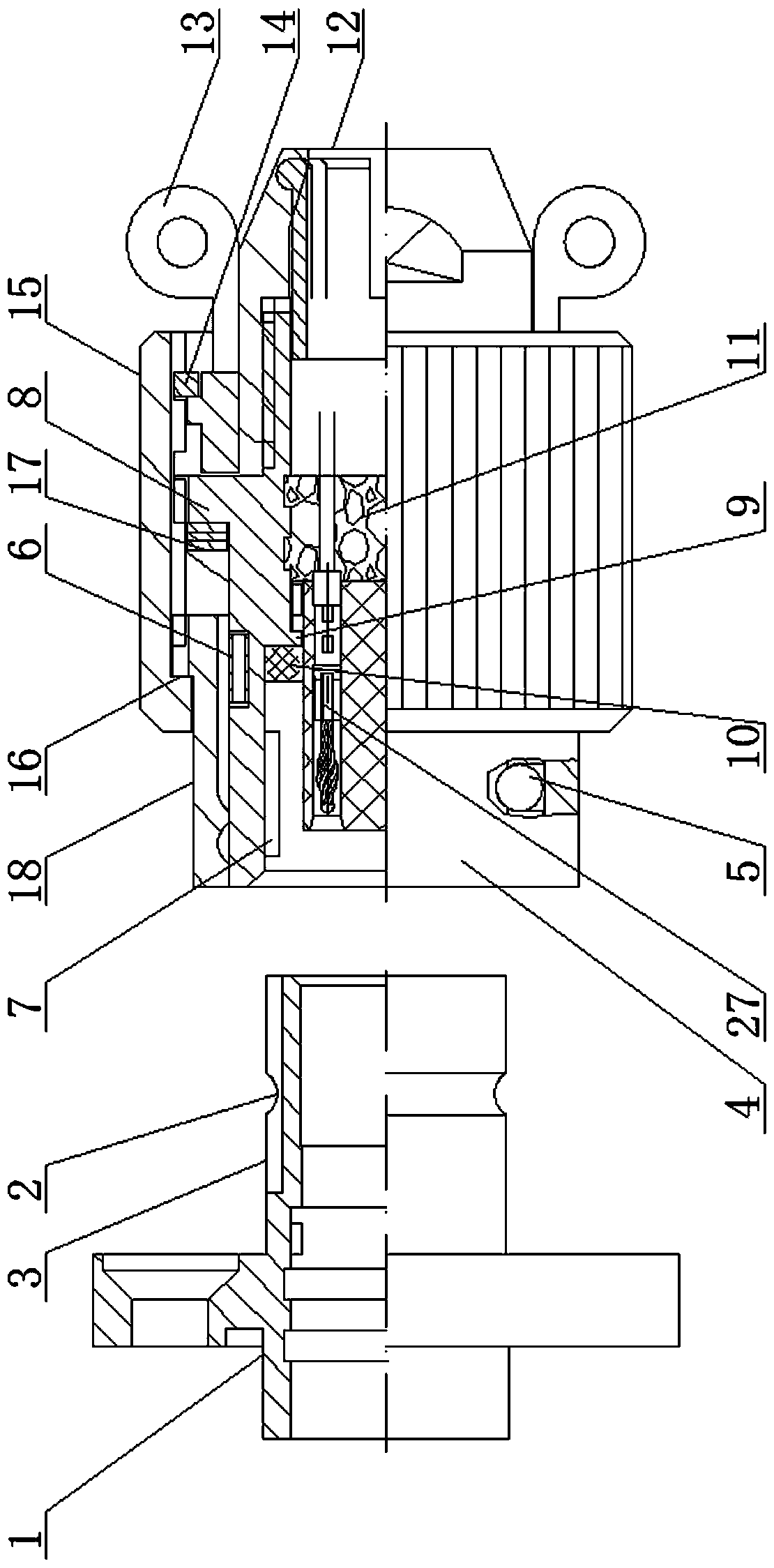

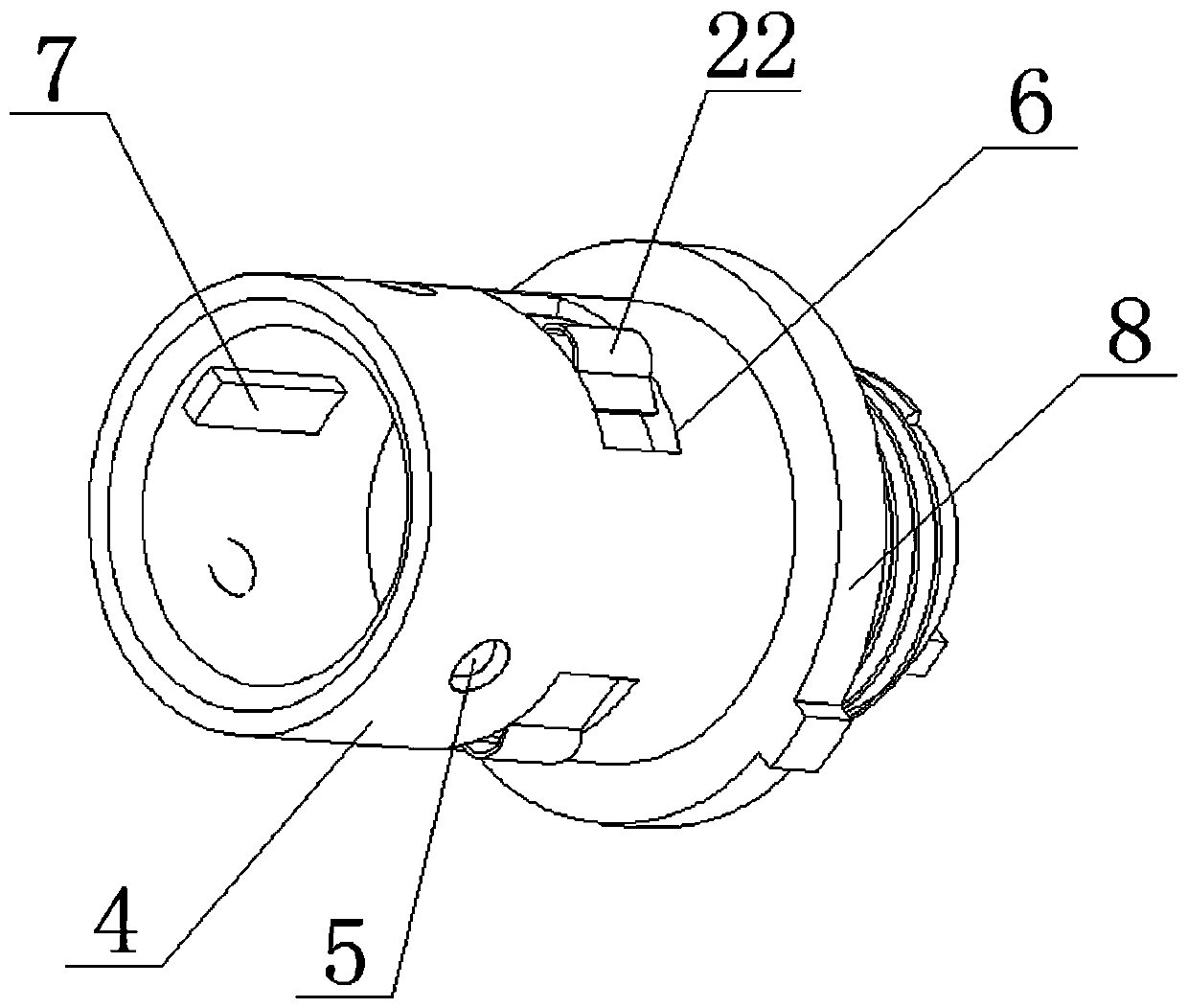

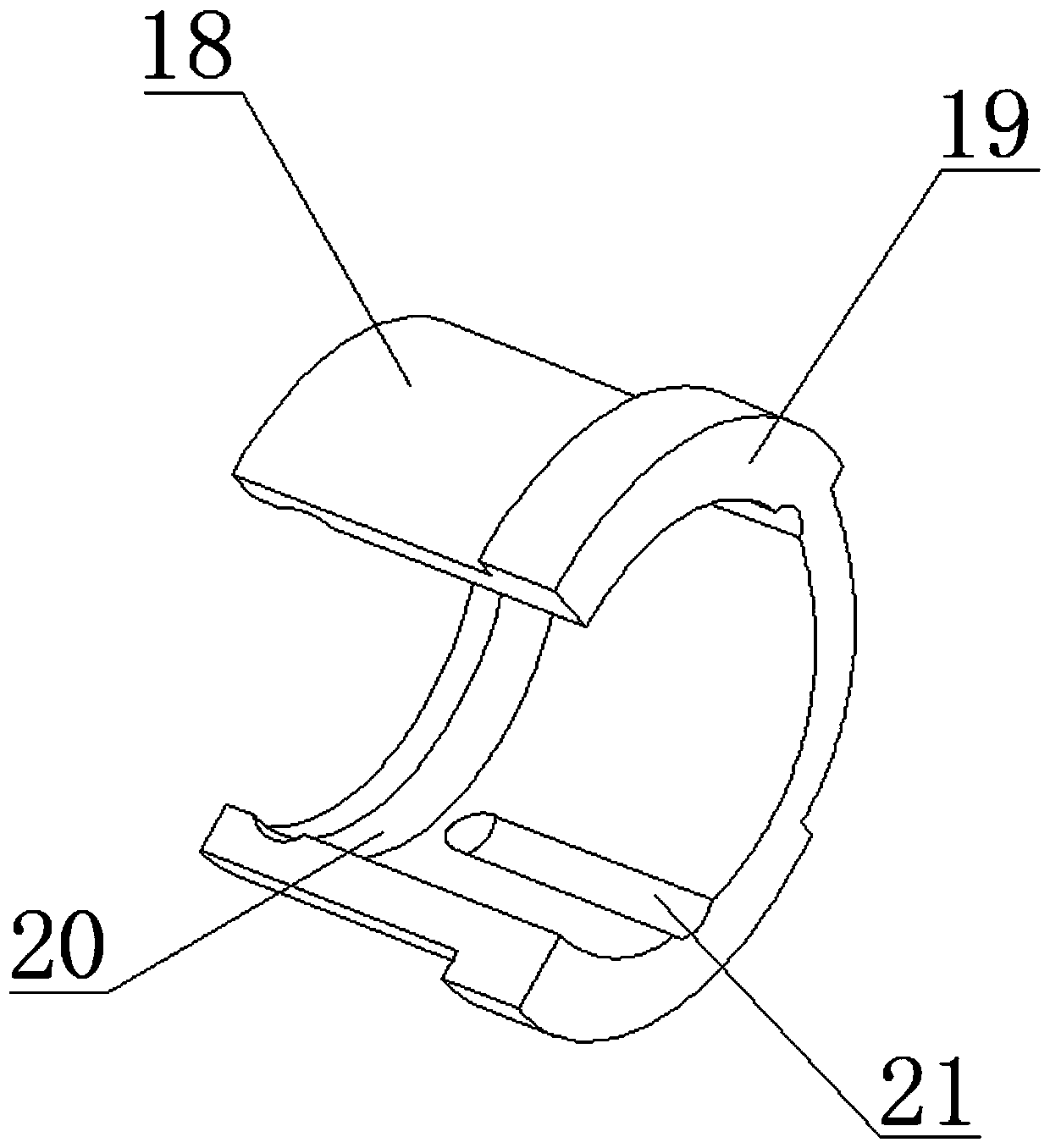

[0022] Further description will be made below in conjunction with drawings and embodiments.

[0023] Figure 1-4 As shown: a spring-type self-locking anti-loosening electrical connector includes a plug and a socket. One end of the seat shell 1 of the socket is inserted into one end of the head shell 4, and a locking ring is provided on the outer circumference of one end of the seat shell 1. The arc-shaped ring groove 2, the outer circumferential wall of the head shell 4 of the plug is provided with more than two steel balls 5 evenly distributed in the radial limit movement, the other end of the head shell is connected to the tail attachment 12, and the flange in the middle of the head shell 8. A nut 15 is connected to the outer circumference guide sleeve, and one end of the nut 15 is provided with an inner step 16, and a locking ring 18 is radially spaced and sleeved between the outer circumference of one end of the head shell and the nut, and the locking ring 18 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com