Polarization plate sheet warping correcting method

A polarizing plate and warping technology, which is applied in the post-processing field of finished polarizing plates, can solve the problems that the re-applied protective film of polarizer cannot fully guarantee the correction of warping, labor cost input, failure, etc., and the accuracy is not high to meet the environmental requirements. Realize the effect of batch correction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Correction end point judgment: After selecting the correcting conditions, first do a correction test on a small amount of warped products, regularly take out and measure whether the warped products meet the customer’s specifications, if they meet the customer’s specifications, it can be judged as the corrected end point, record the correcting conditions, and carry out scale Heavy volume correction; the ideal end point of correction is zero warpage at the four corners and four sides.

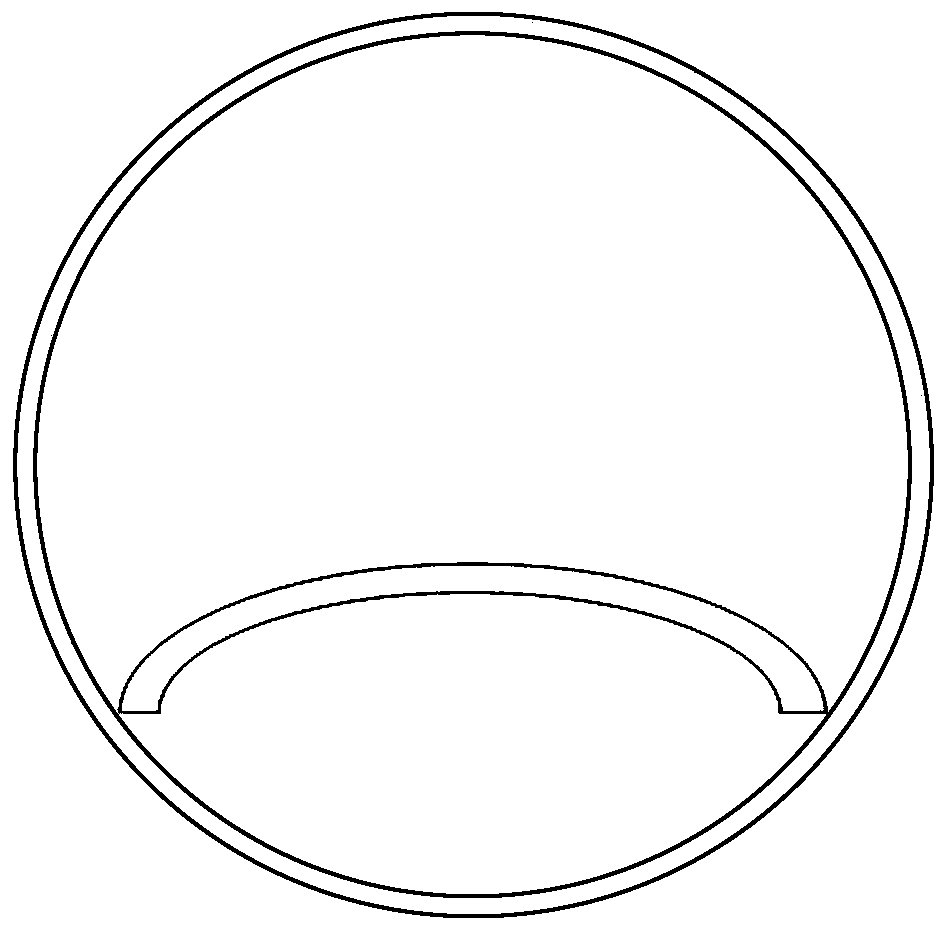

[0028] Put the warped NG polarizer sheet into the cylinder, such as Figure 1-3 As shown, the correction conditions are shown in Table 1, and the correction results are shown in Table 2.

[0029] Table 1 List of Correction Conditions

[0030] corrective condition temperature humidity cylinder Sheet thickness Sheet size correction time parameter 40℃ 40% 12 inches 306μm 19 inches 24hr

[0031] Table 2 Correction result measurement table

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com