Patents

Literature

30 results about "Cost aspects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

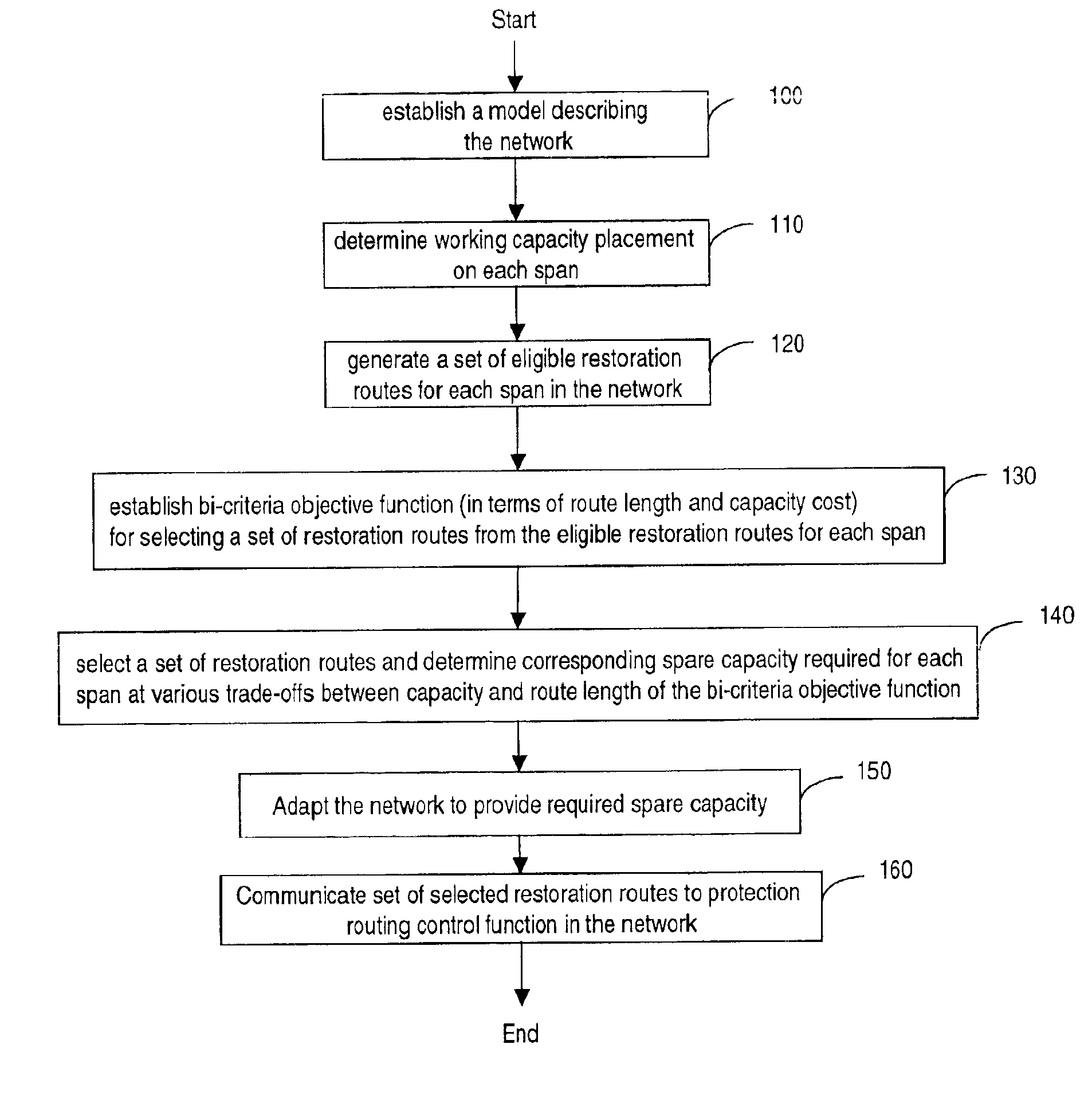

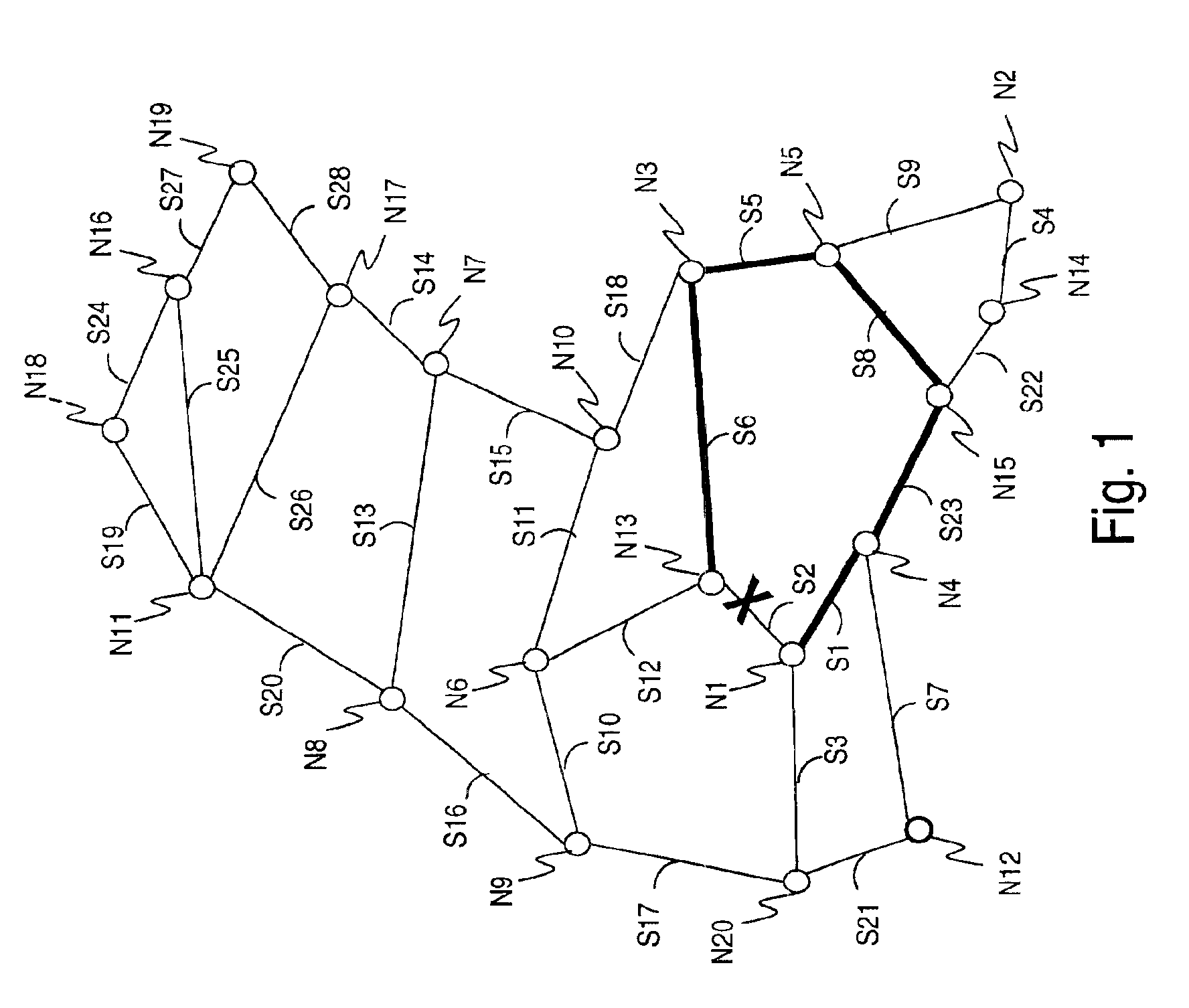

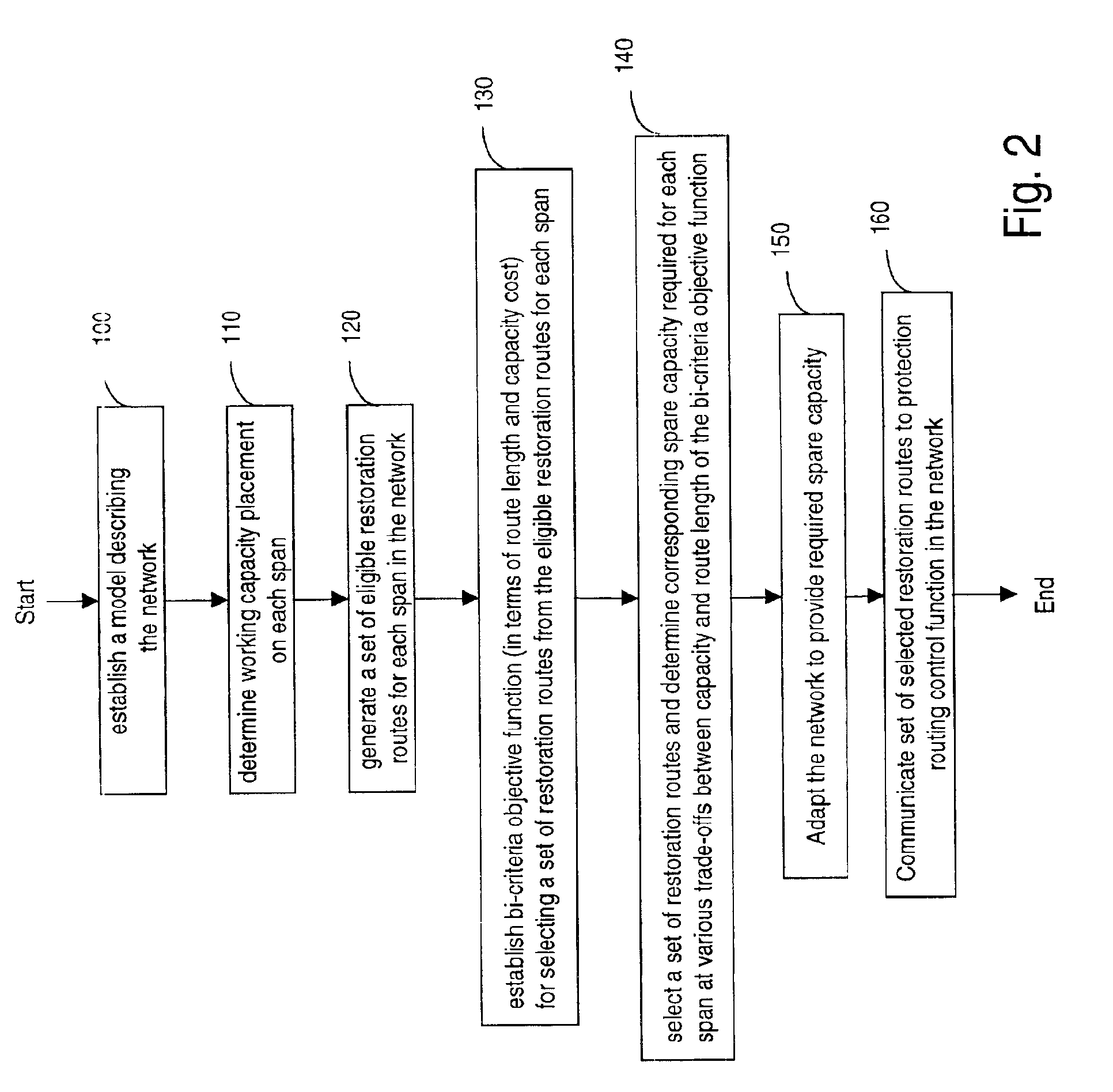

Method of providing restoration routes in a mesh network

InactiveUS6856592B2Capacity costShorten the lengthError preventionFrequency-division multiplex detailsEngineeringMesh networking

A method of providing restoration routes for protecting traffic in a mesh network is described. The method comprises the steps of generating a set of eligible restoration routes for each span in the network, establishing a bi-criteria objective function in terms of route length and capacity cost for selecting a set of restoration routes, and selecting a set of restoration routes for each span from the eligible restoration routes in dependence upon the bi-criteria objective function. Embodiments of the invention may be useful for shortening the lengths, in terms of hops, of existing restoration routes in a mesh-restorable network and in some cases with negligible spare capacity penalty.

Owner:CIENA

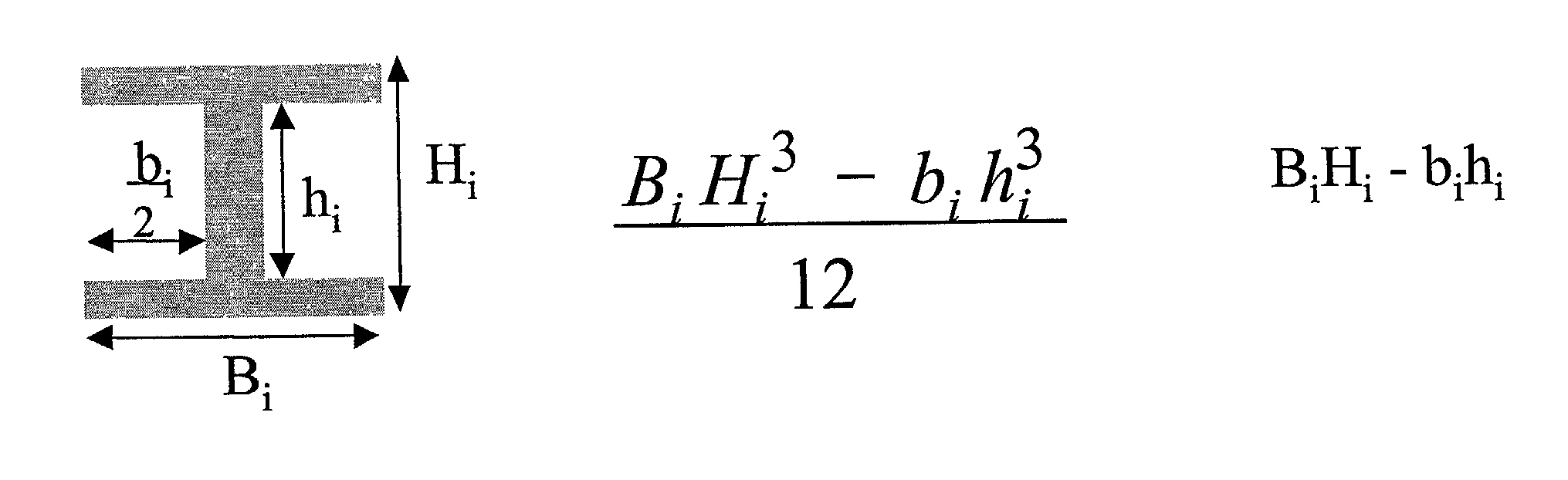

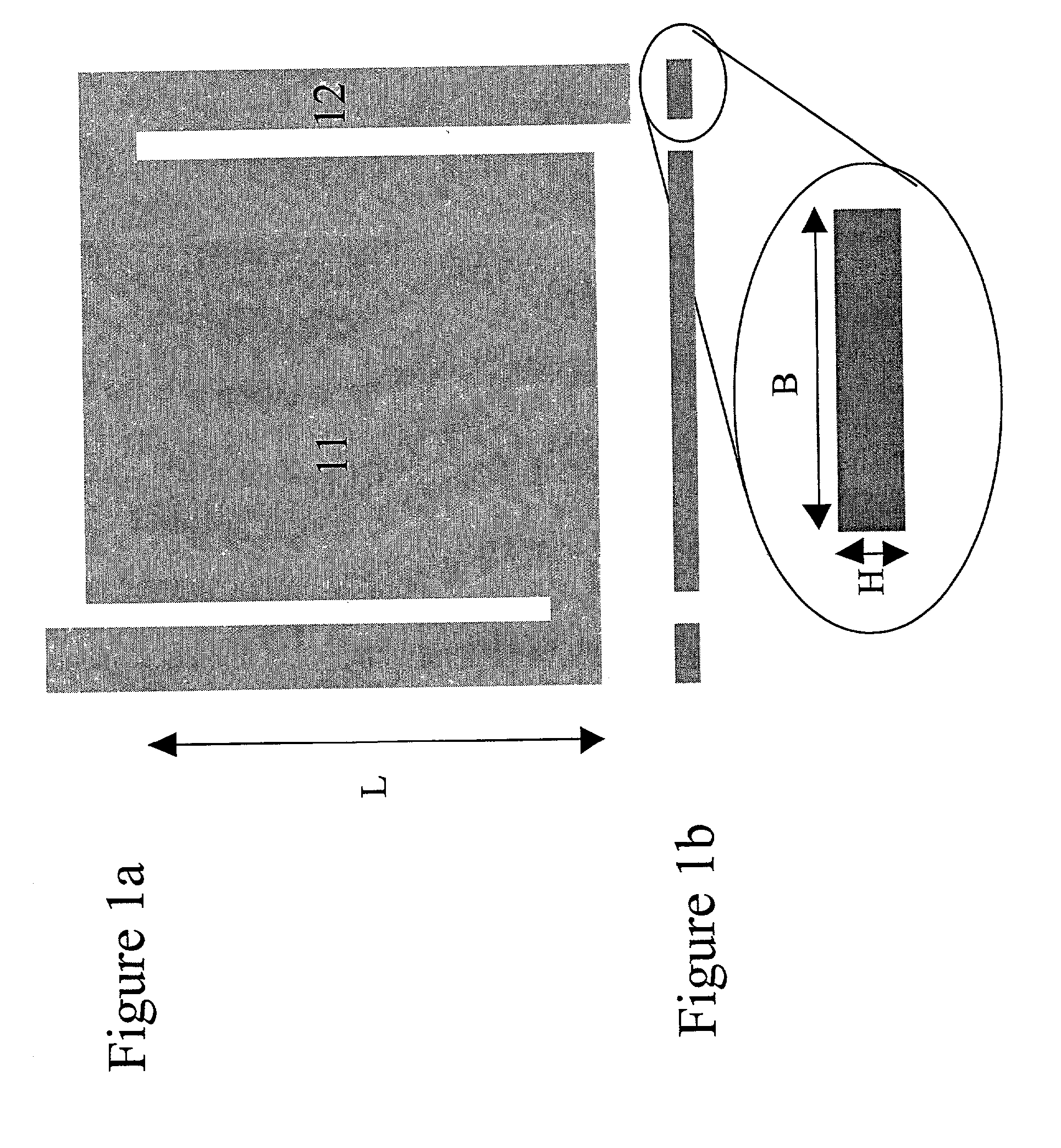

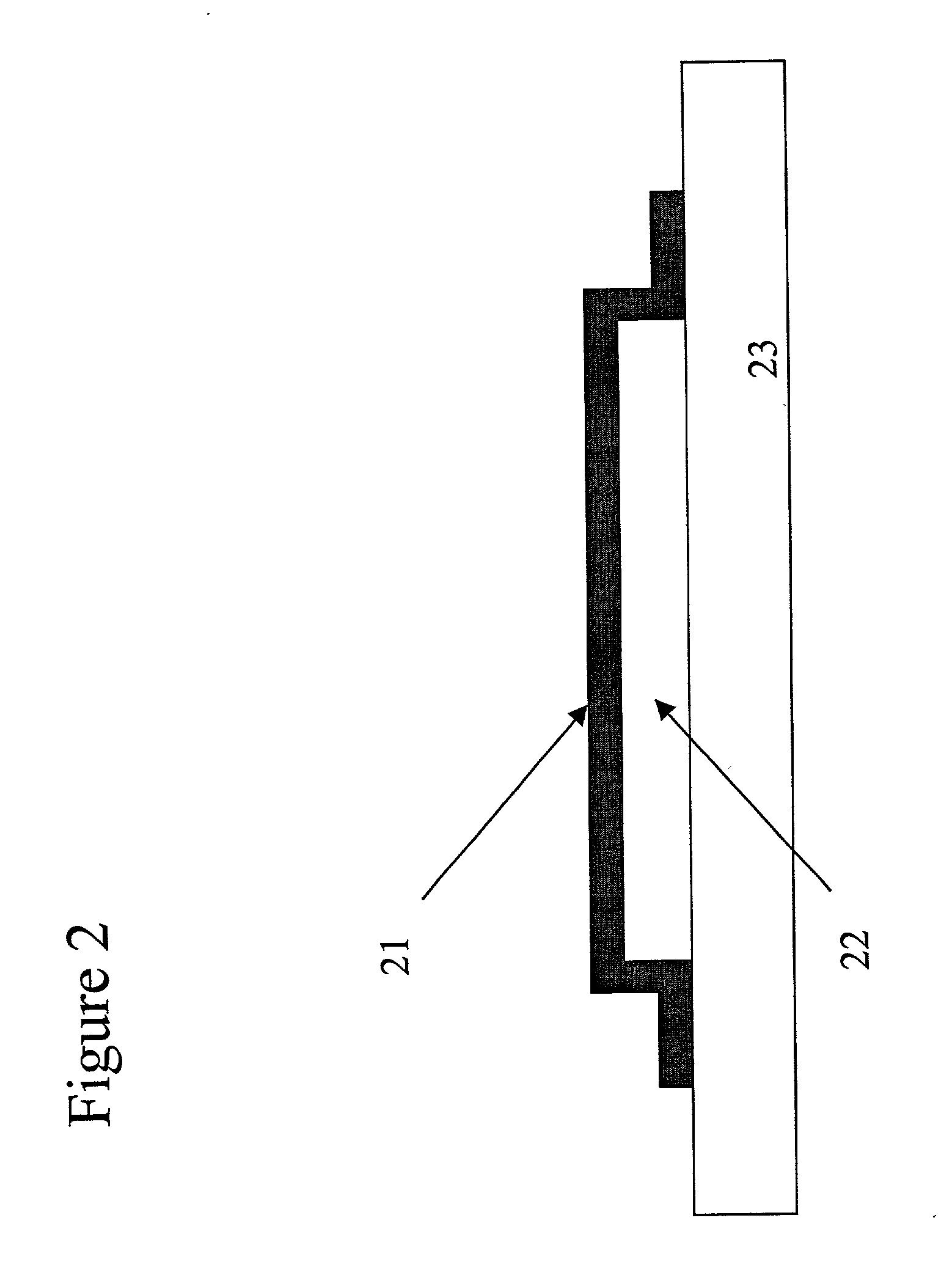

Method for improving mechanical strength in micro electro mechanical systems and devices produced thereof

InactiveUS20020009821A1High mechanical strengthFast readoutSemiconductor/solid-state device manufacturingPyrometry using electric radation detectorsThermal insulationEngineering

Structures and methods are disclosed to produce mechanical strength in Micro Electro Mechanical Systems by increasing the moment of inertia of some of the composing elements. In one aspect, a thermal sensor with improved mechanical strength, thermal insulation and time constant is achieved. Moreover, the current method and apparatus is advantageous in terms of process time and process cost, particularly in the area of lithographic patterning.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

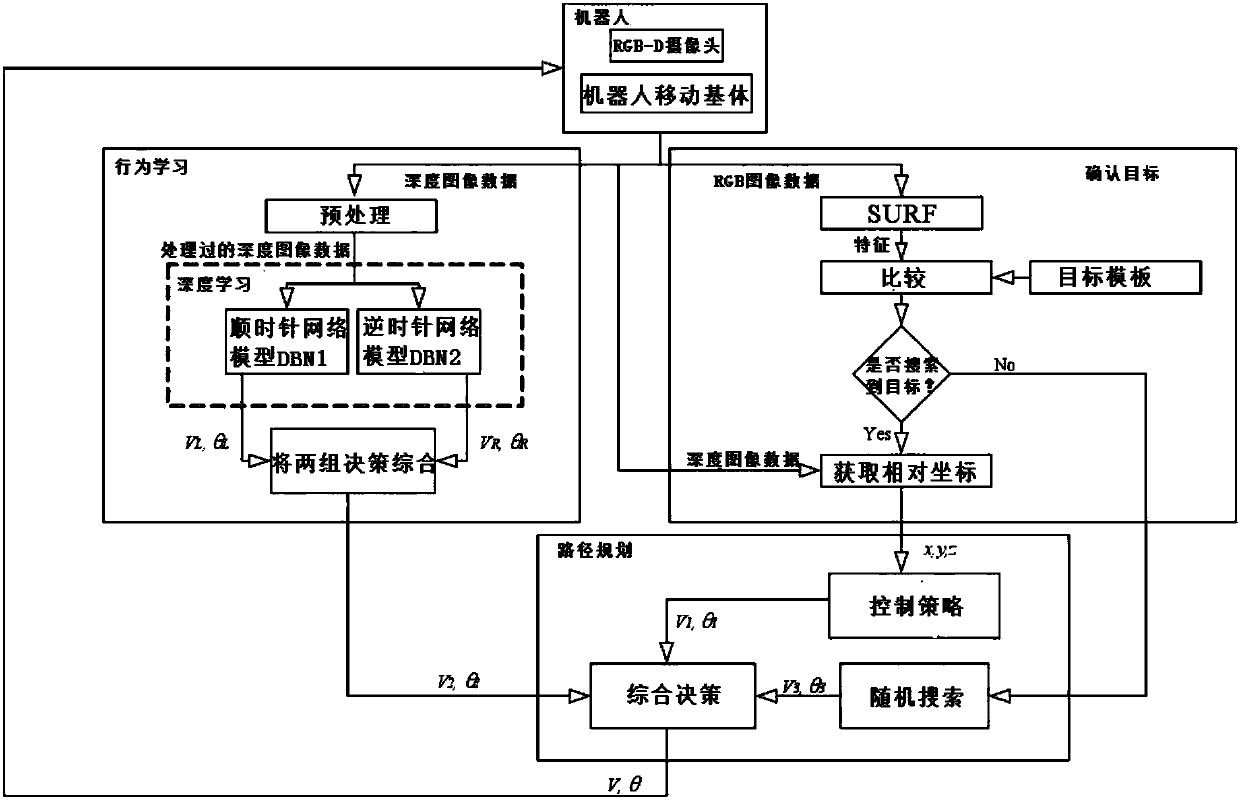

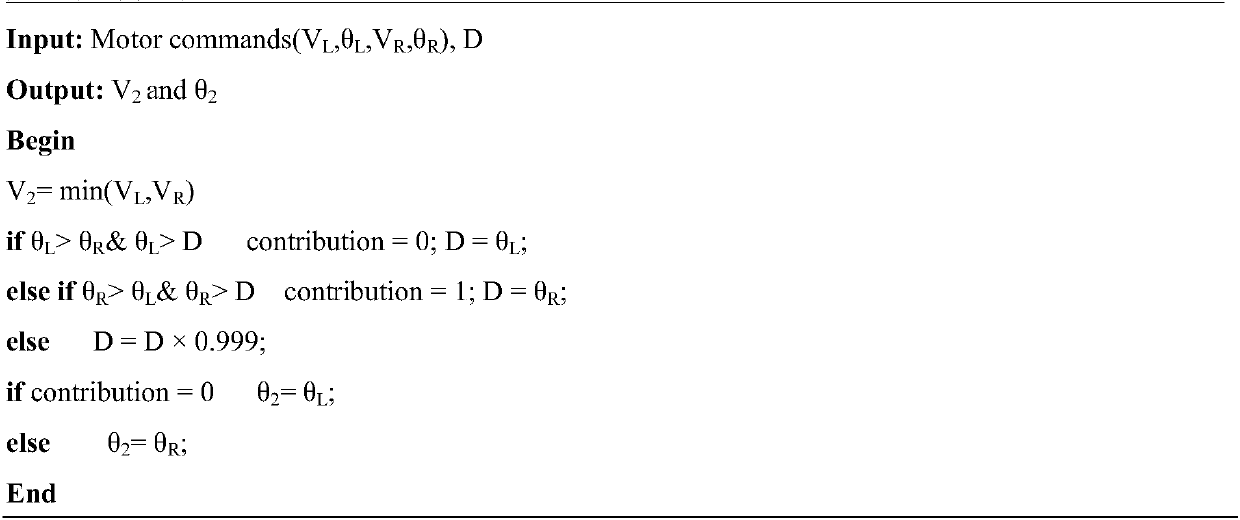

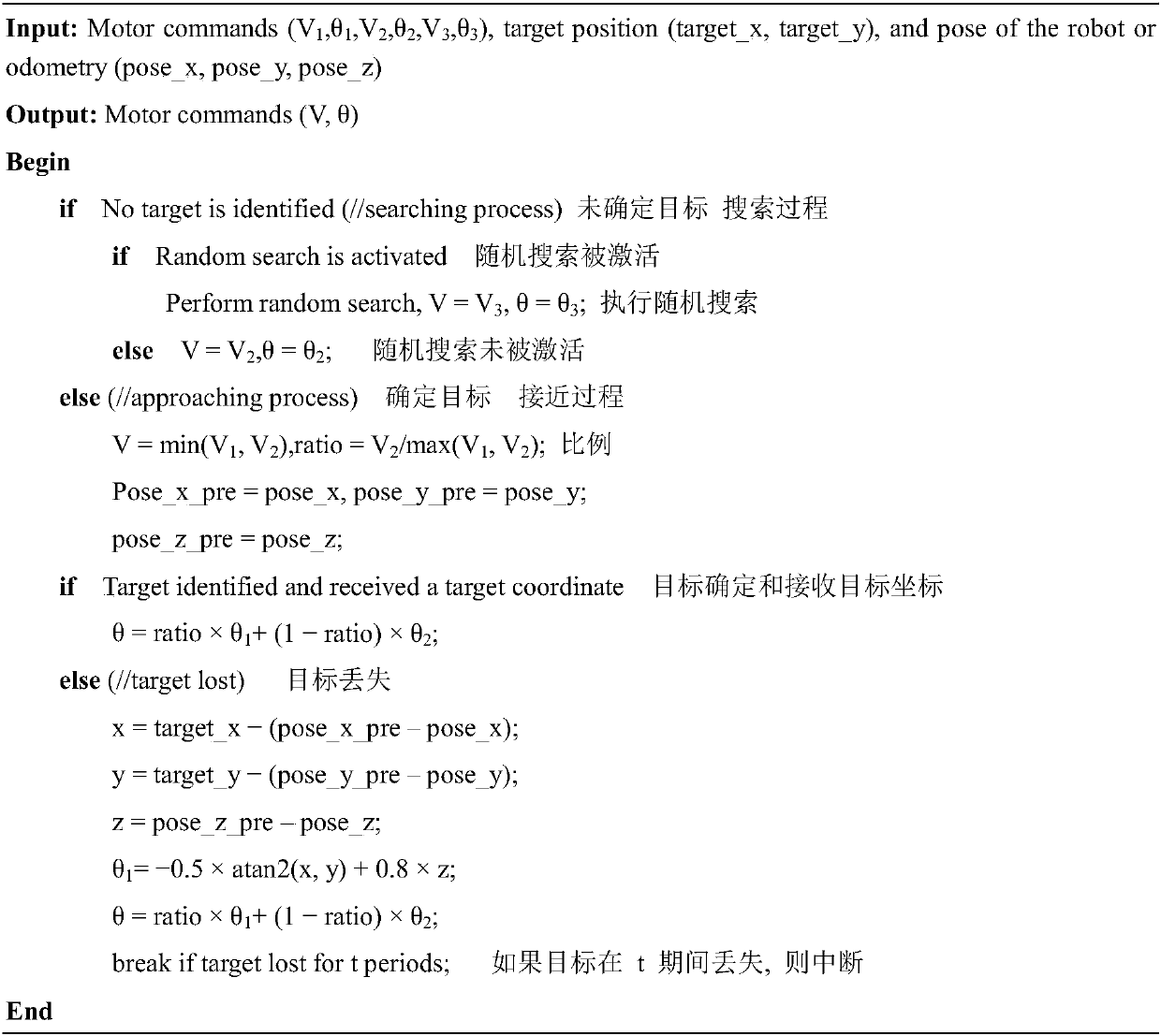

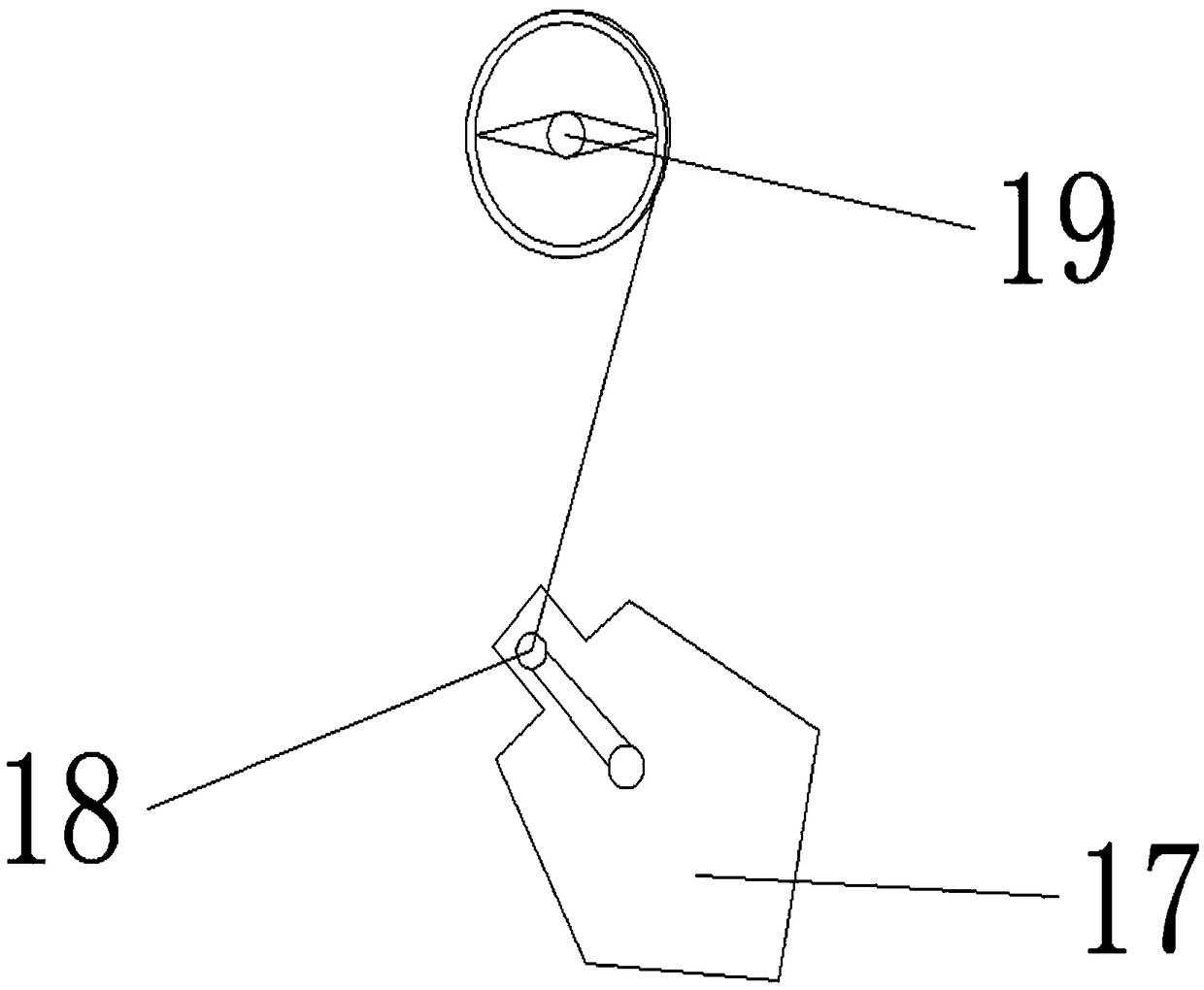

Robot obstacle avoidance behavior learning and target searching method based on deep belief network

ActiveCN107818333AHigh cost feasibilityGood automatic obstacle avoidance learning abilityProgramme-controlled manipulatorForecastingDeep belief networkAngular velocity

The invention discloses a robot obstacle avoidance behavior learning and target searching method based on a deep belief network. The robot obstacle avoidance behavior learning and target searching method based on a deep belief network includes the steps: controlling a robot to realize obstacle avoidance in the environment, acquiring the color, the deep image data, and the linear velocity and the angular velocity corresponding to a mobile matrix of the robot at the same time, and based on the data, constructing a network model of implementing automatic obstacle avoidance behavior learning of the robot; during the automatic target searching process of the robot, randomly searching the target in the environment through the automatic obstacle avoidance function, and once searching the target,directly approaching the target, wherein if the obstacle appears during the approaching process, the robot can avoid from the obstacle and perform path planning again, and if the target is lost duringthe approaching process, the robot randomly searches again; and continuously repeating the above process until the robot arrives at the target position. The robot obstacle avoidance behavior learningand target searching method based on a deep belief network only uses a single RGB-D camera to realize path planning and target searching with the automatic obstacle avoidance function, and has higherfeasibility and practicality in the cost aspect and the application aspect.

Owner:爱极智(苏州)机器人科技有限公司

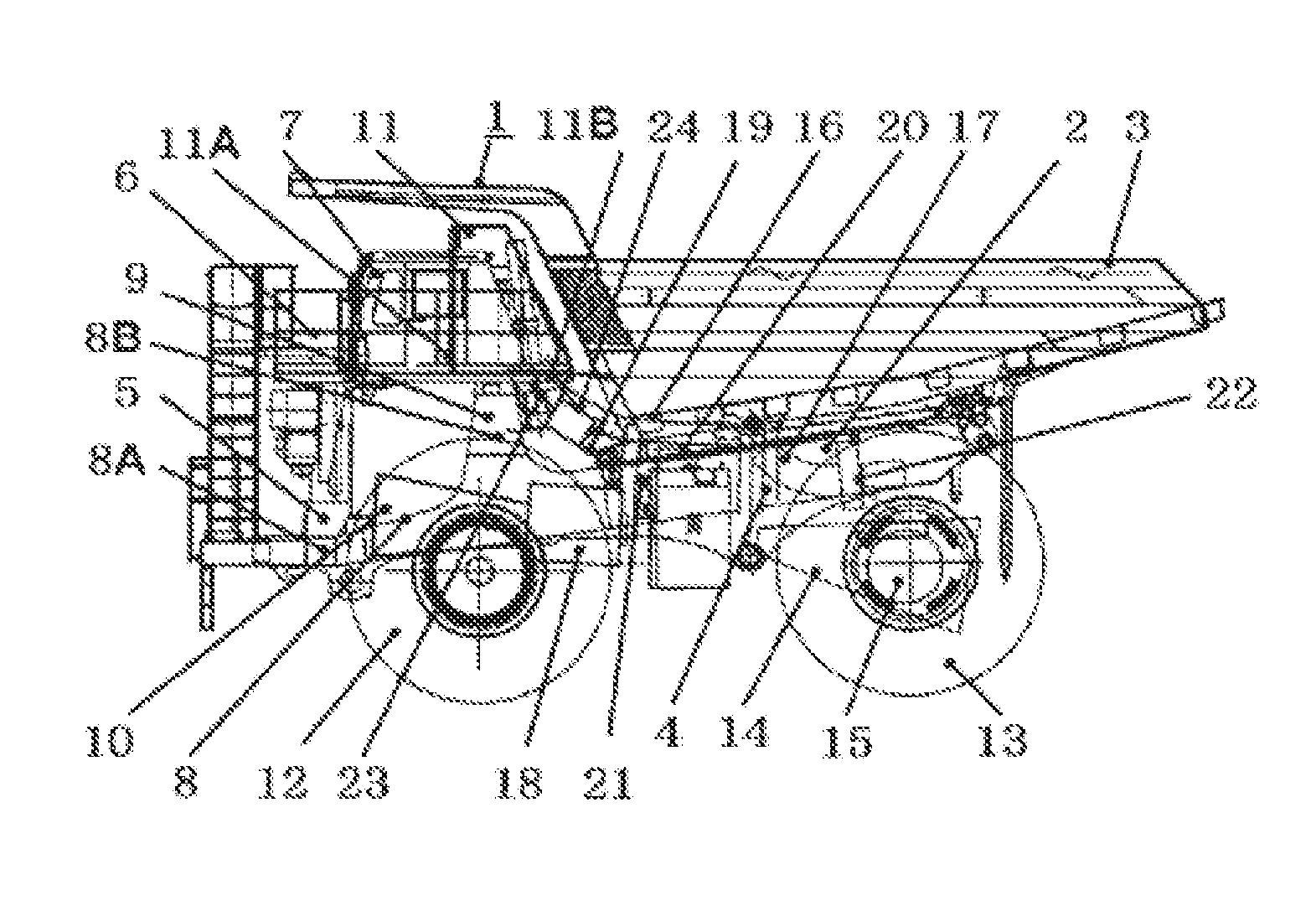

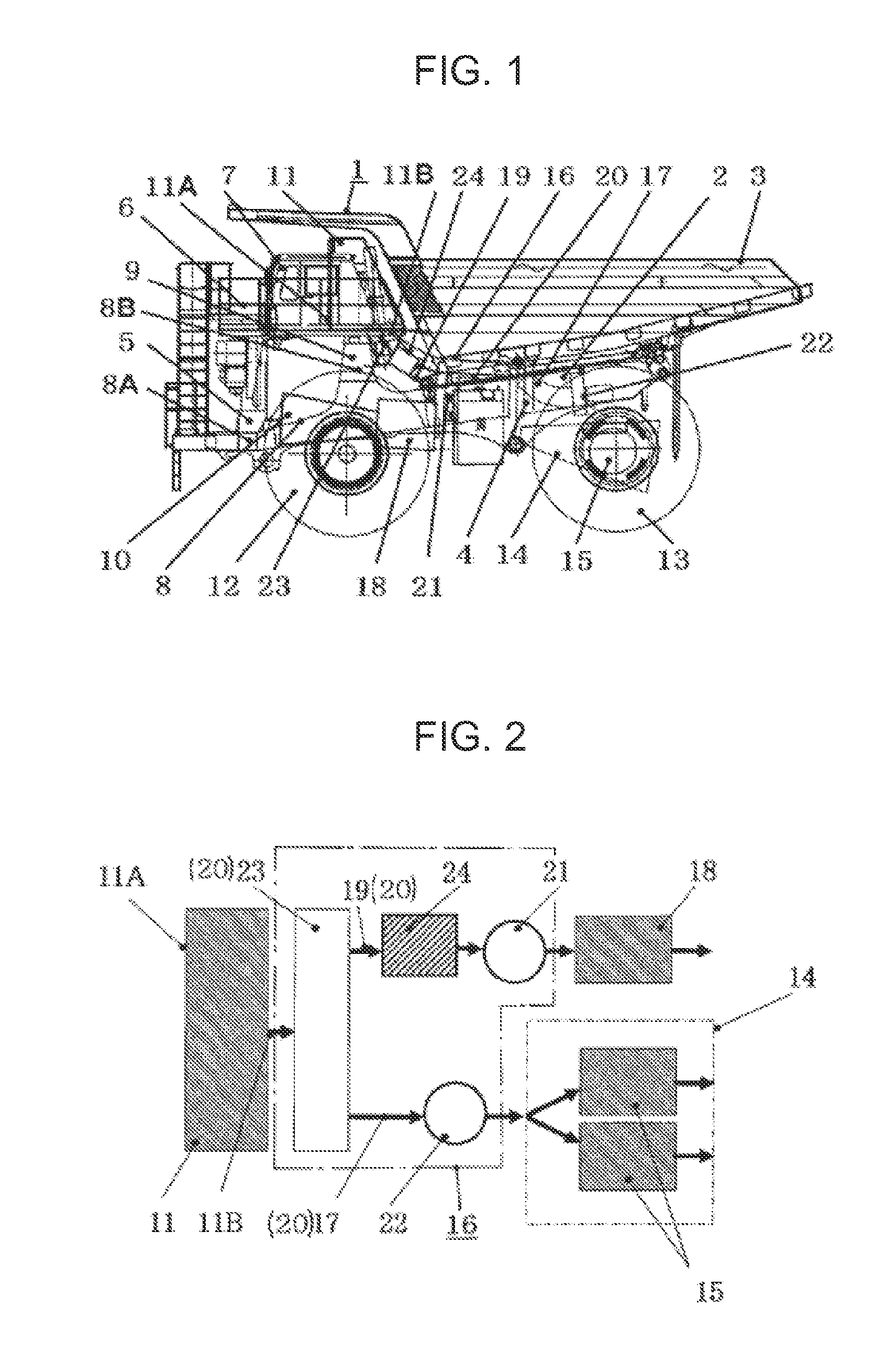

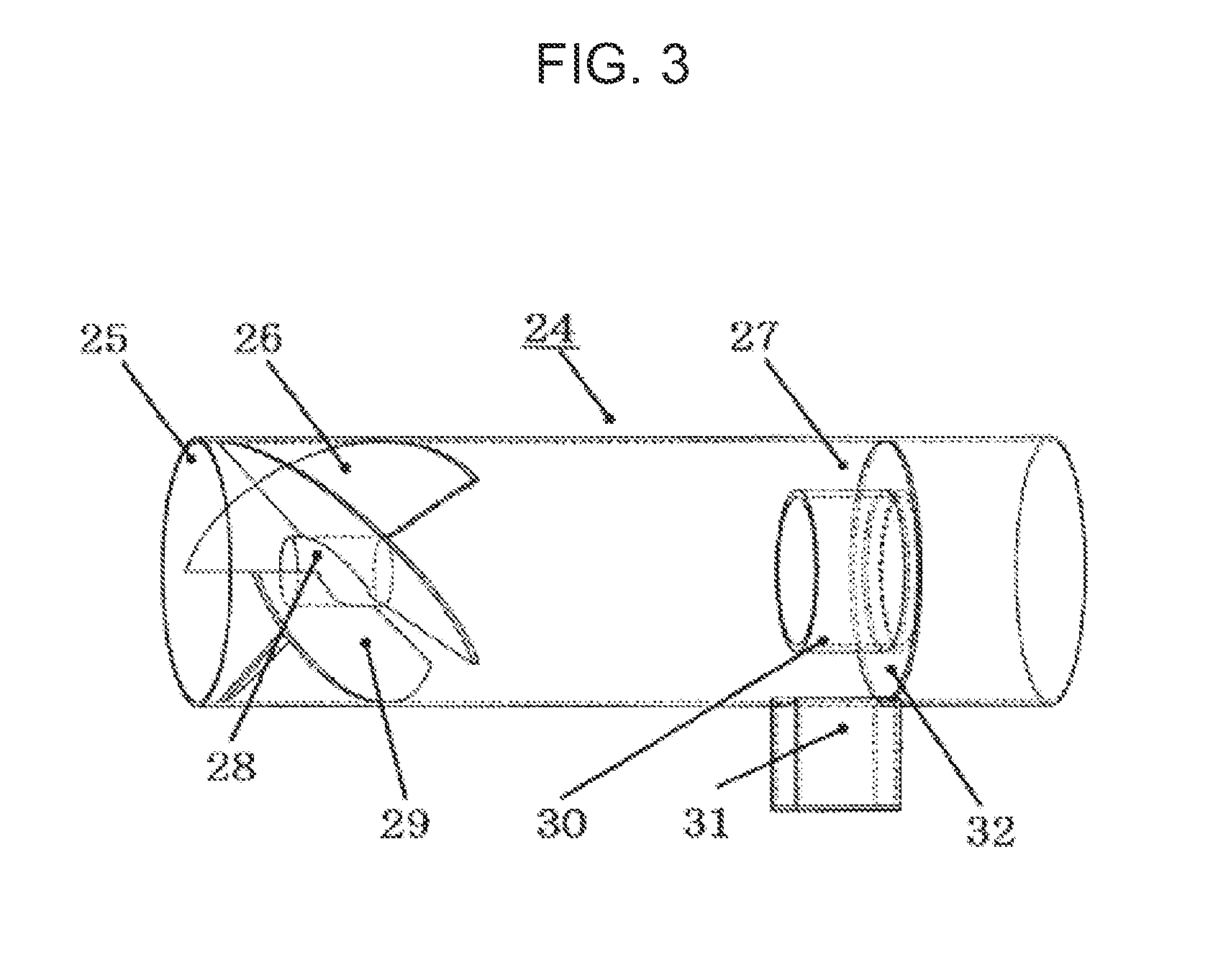

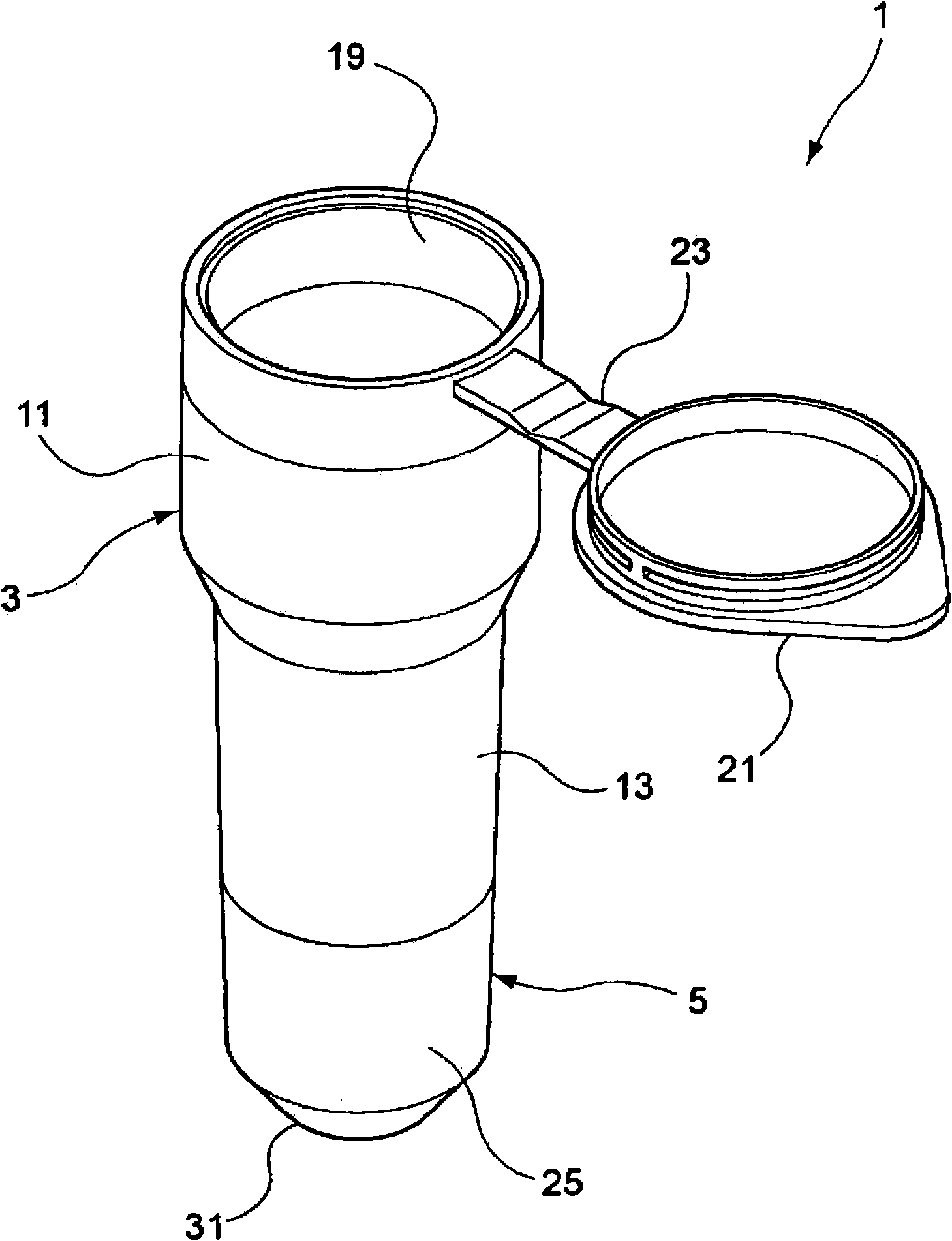

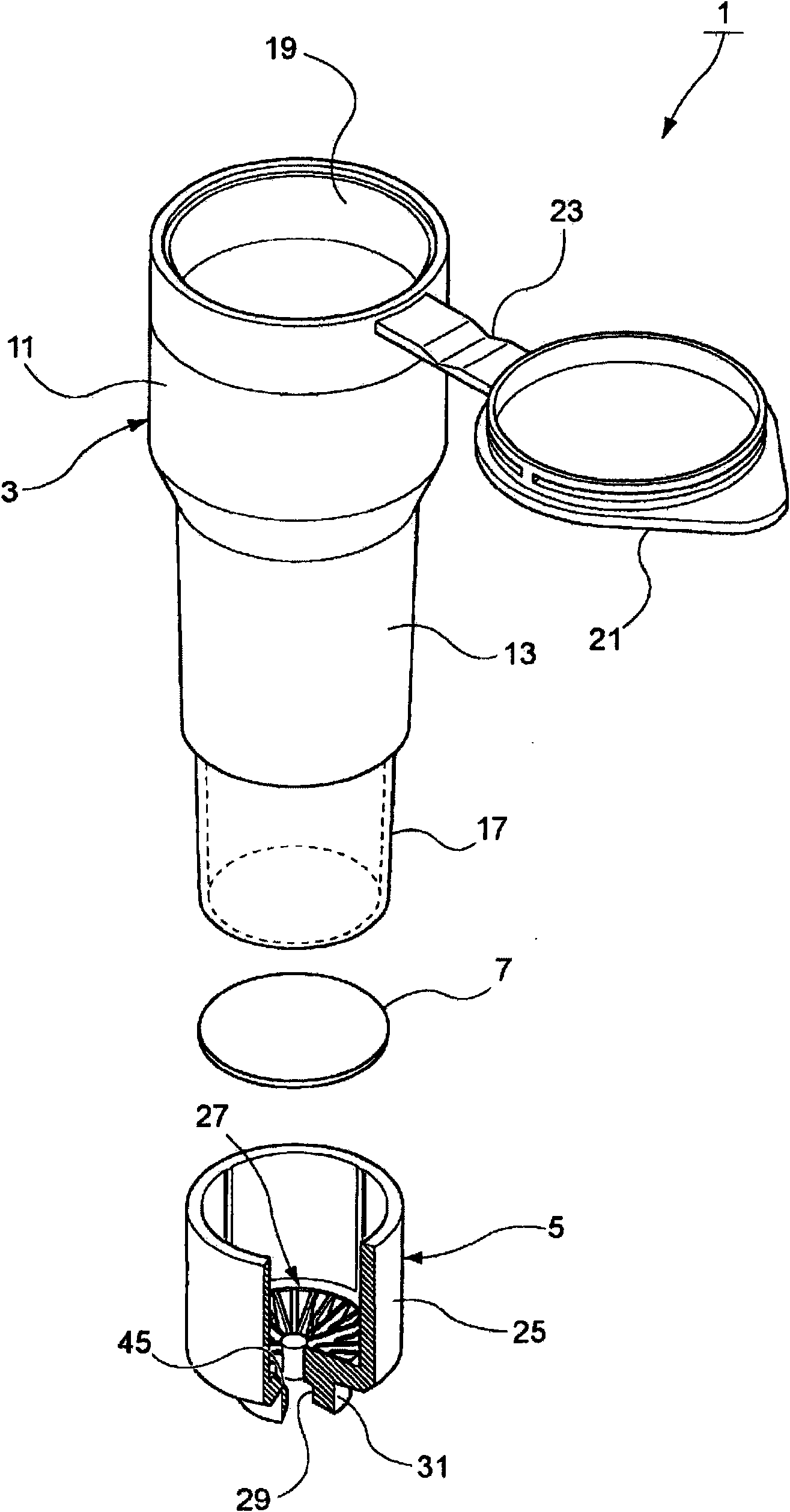

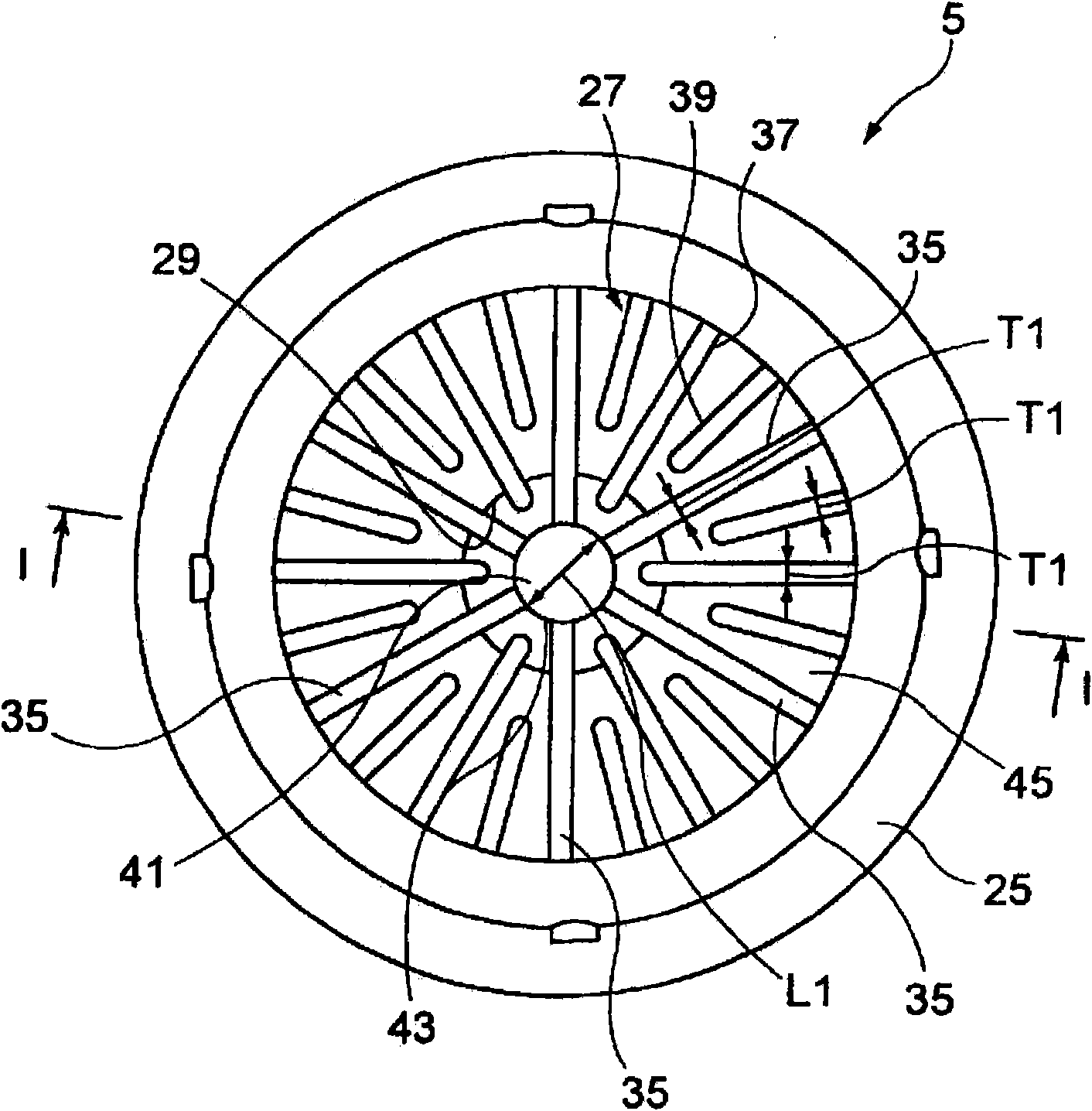

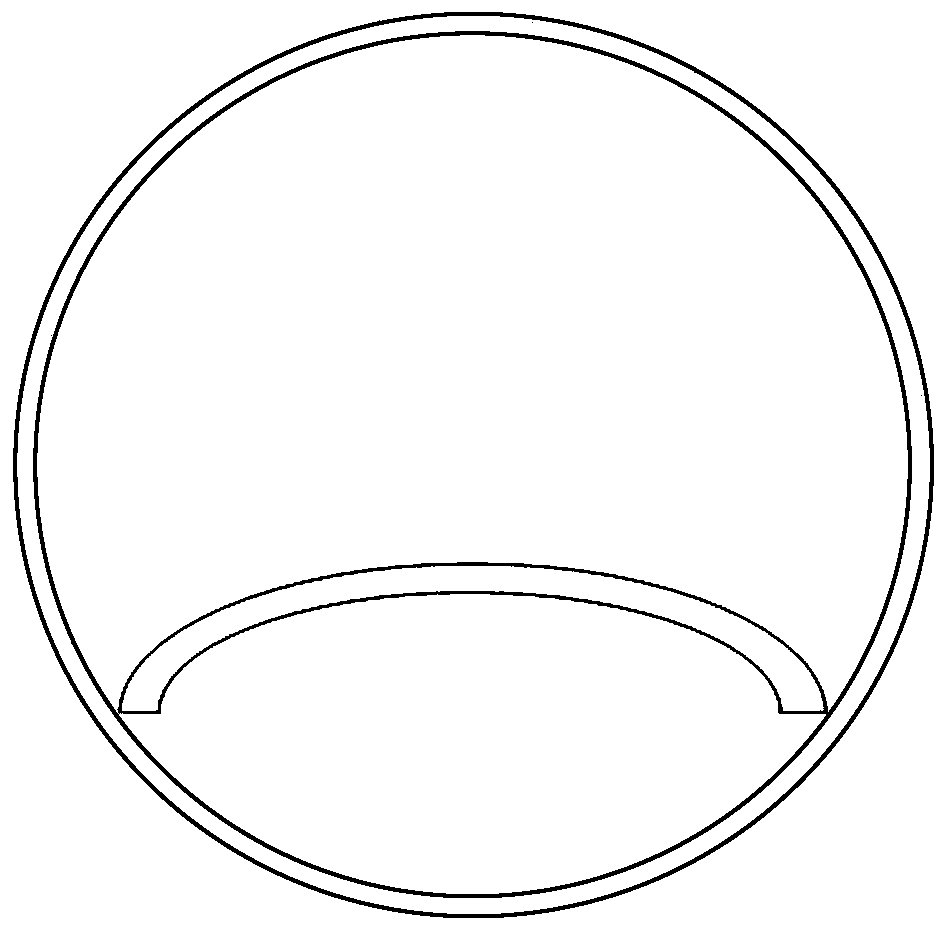

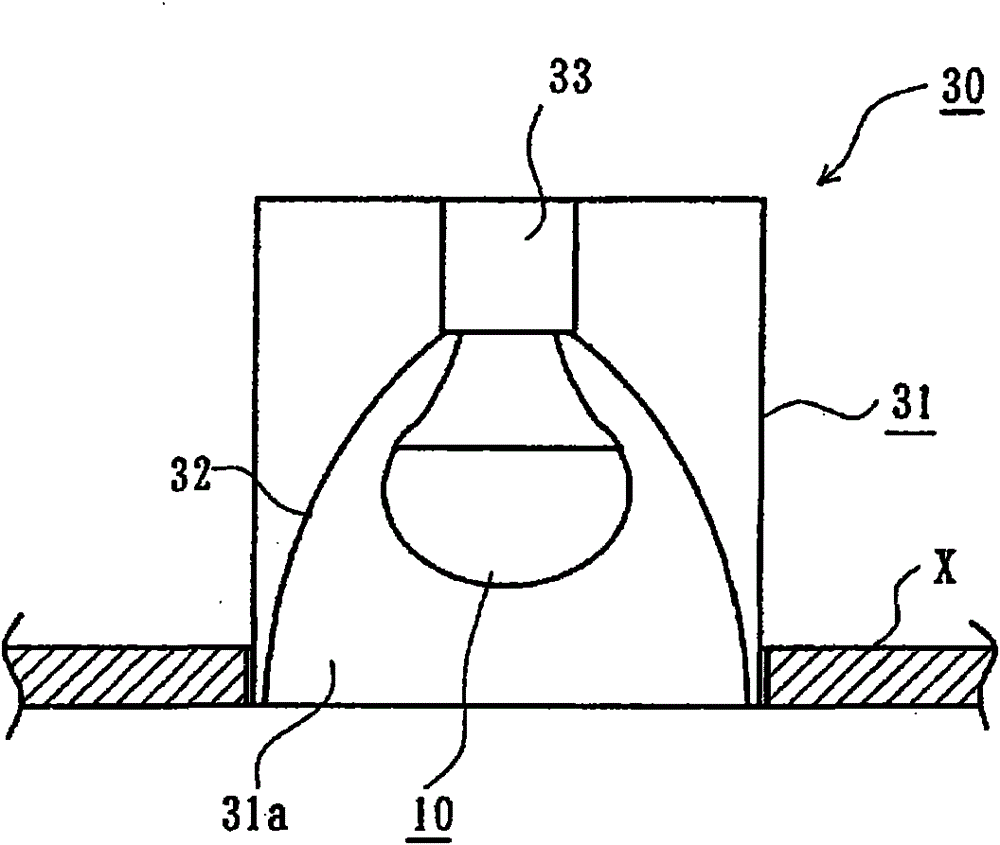

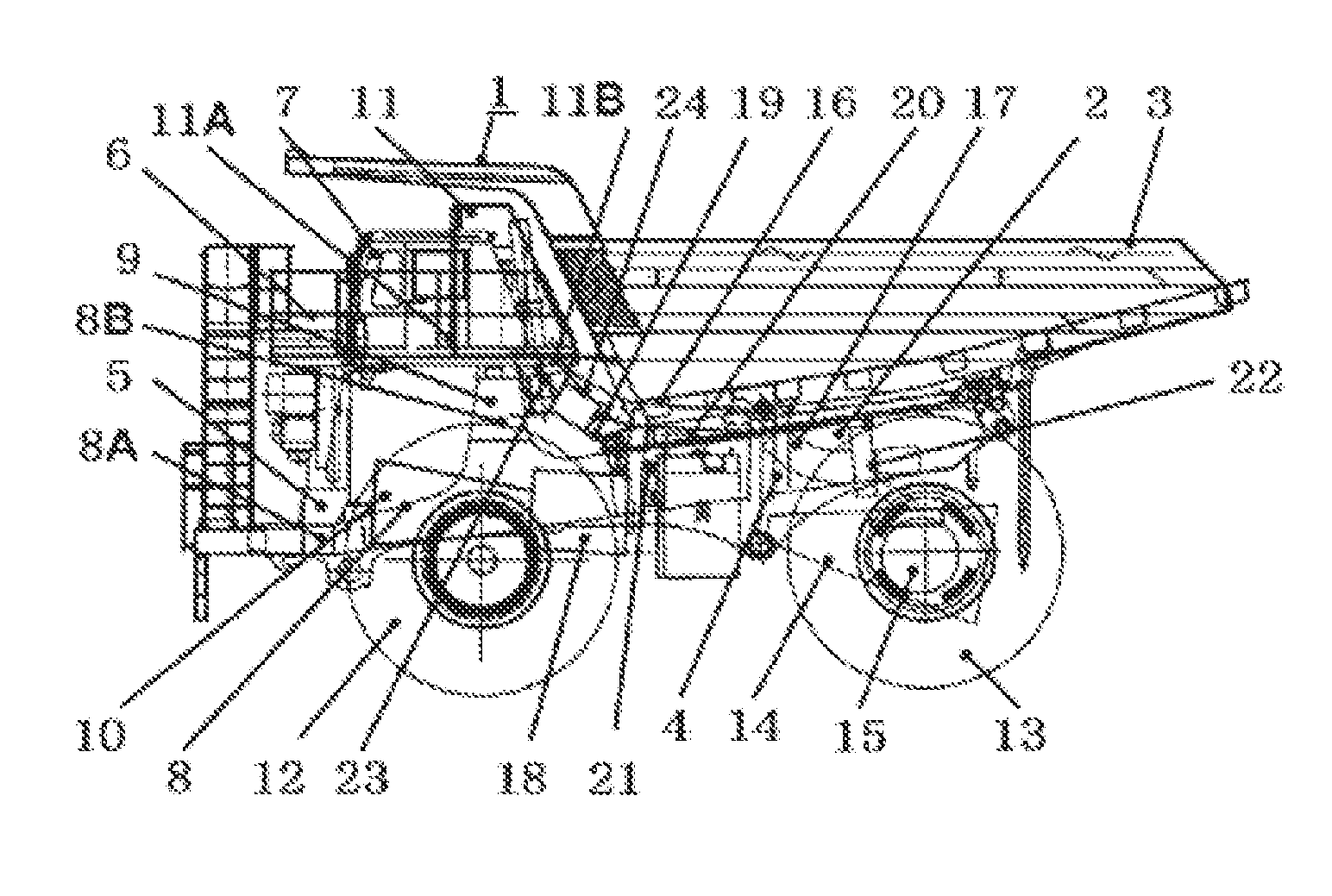

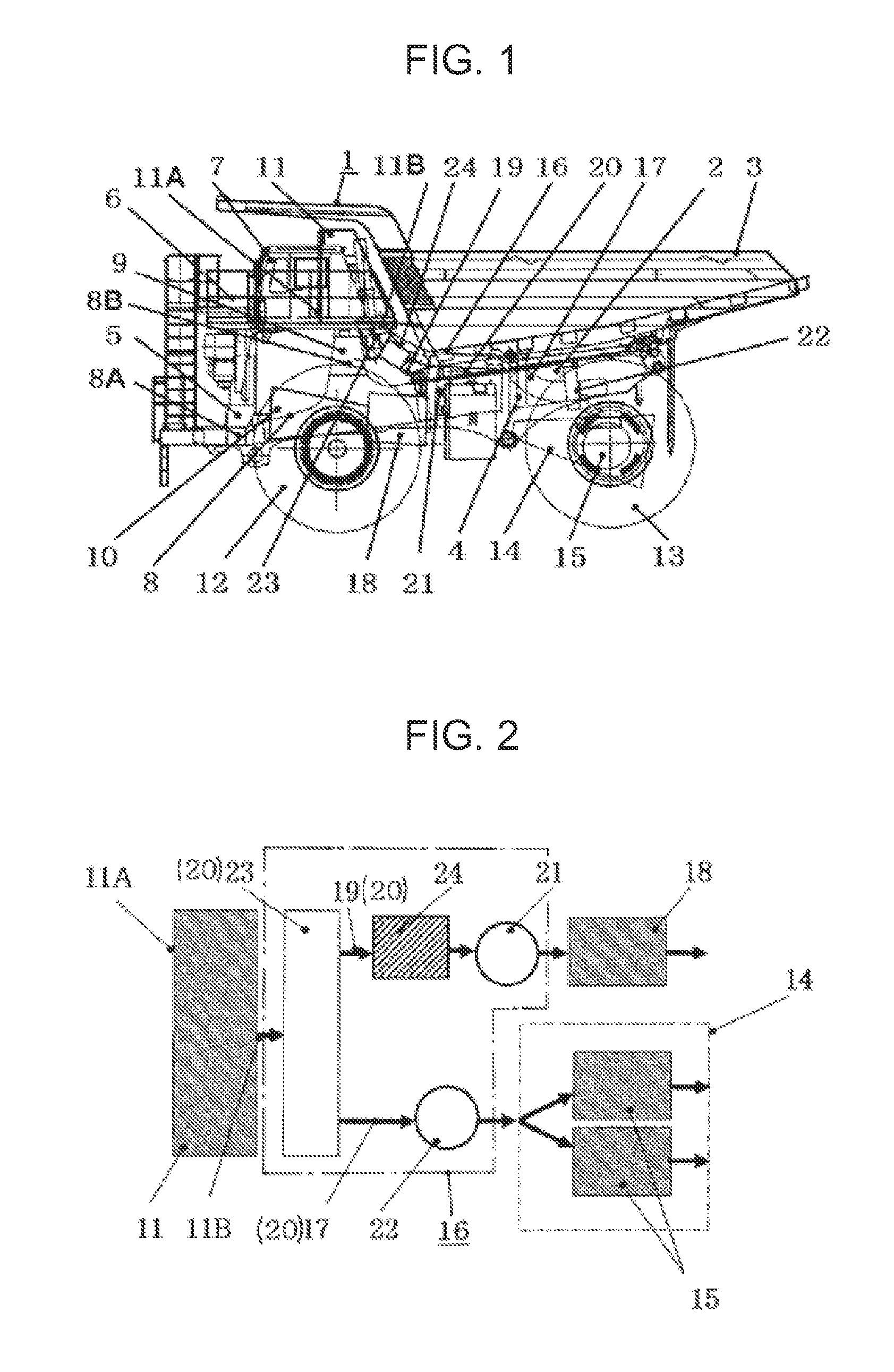

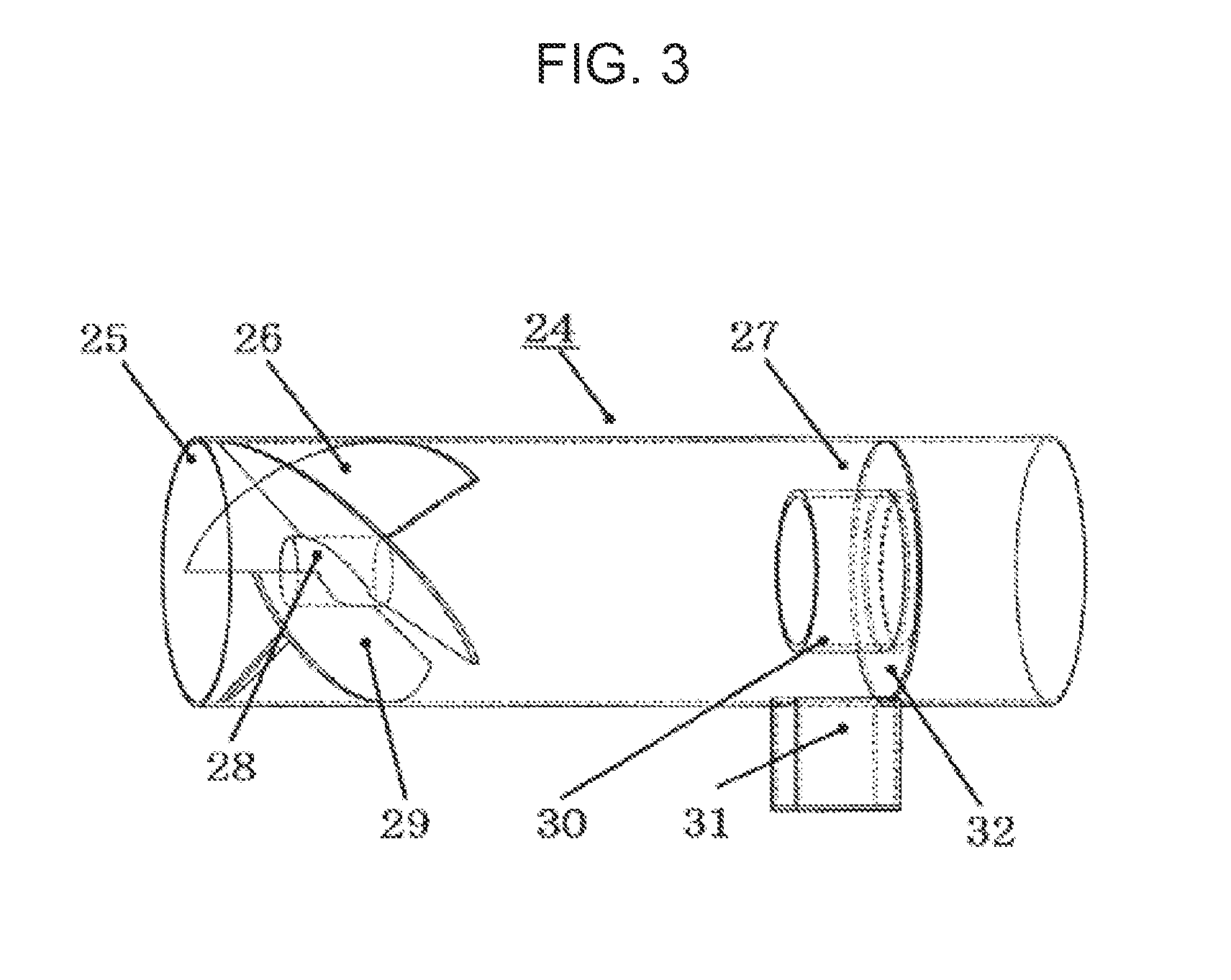

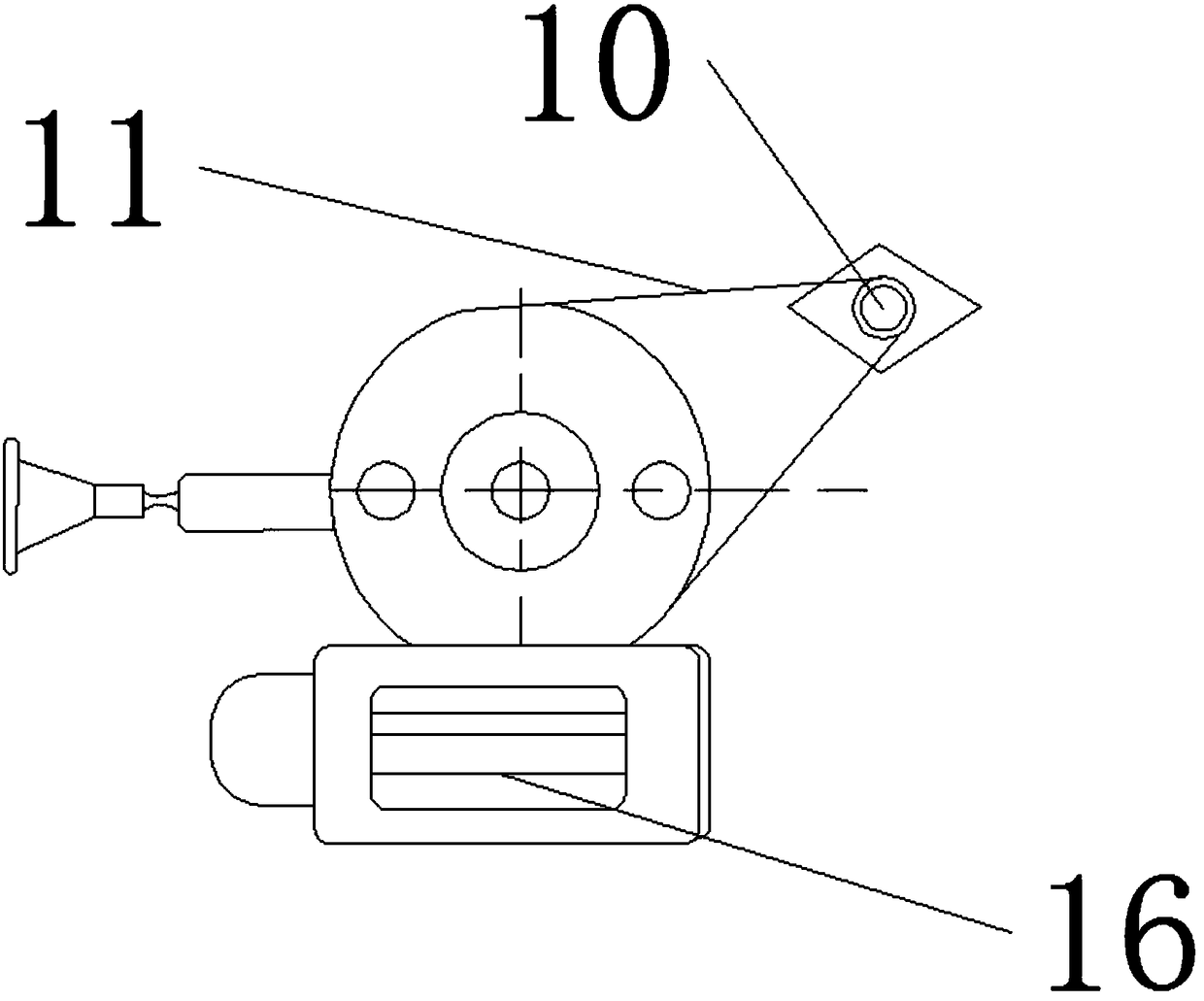

Transport Vehicle, and Transport Vehicle Air Cleaner

Provided is a haulage vehicle having an air cleaner that is realistic from the viewpoints of fabrication steps and cost aspect. An air cleaner (24) arranged in a haulage vehicle is provided with a swirling flow generator (26), a separator (27) and an outer cylindrical casing (25). The swirling flow generator has a fixed shaft (28) and a plurality of guide blades (29) arranged and shifted from one another over a predetermined angle in a direction in which the guide blades rotate about the fixed shaft, and by the plurality of guide blades, a swirling flow of cooling air is generated. The separator has a flange (32) attached on and along an inner peripheral wall of the outer cylindrical casing (25), an inner cylindrical member (30) arranged on an outer edge of a center bore of the flange, and a collection pocket (31). Dust contained in the cooling air is taken by the swirling flow into a space between the inner cylindrical member and the outer cylindrical casing and is allowed to accumulate in the collection pocket.

Owner:NIHON KENKI CO LTD

Porous filter cartridge

InactiveCN101925396AImprove filtering effectEfficient extractionWithdrawing sample devicesUltrafiltrationFiltrationWaste management

This aims to provide a porous filter cartridge which is hardly contaminated, which is advantageous in the cost aspect, and which can perform efficient filtration and extraction without any breakage. The porous filter cartridge includes a porous filter retained in the bottom and inside of a bottomed cylindrical cap 5 having a discharge opening 29 formed in the center of the bottom. A plurality of ribs 35, 37 and 39 for supporting the porous filter are erected radially around the discharge opening 29 in the bottom of the cap 5. At least any of those ribs is connected across the discharge opening 29 at the central portion of the discharge opening 29, and a protruding face 41 protruding toward the porous filter is formed on the crest face of a connected rib portion 43.

Owner:KURASHIKI BOSEKI KK

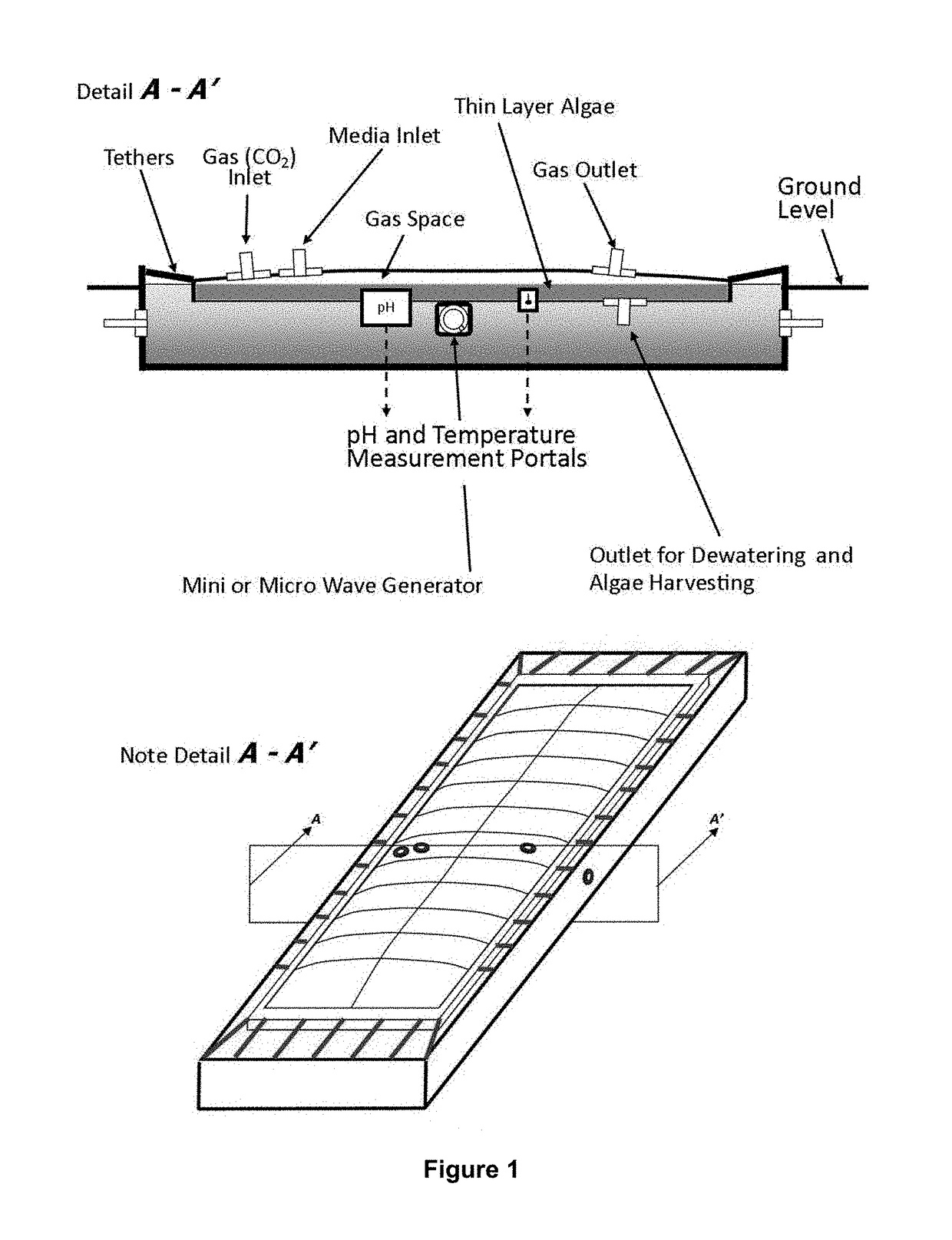

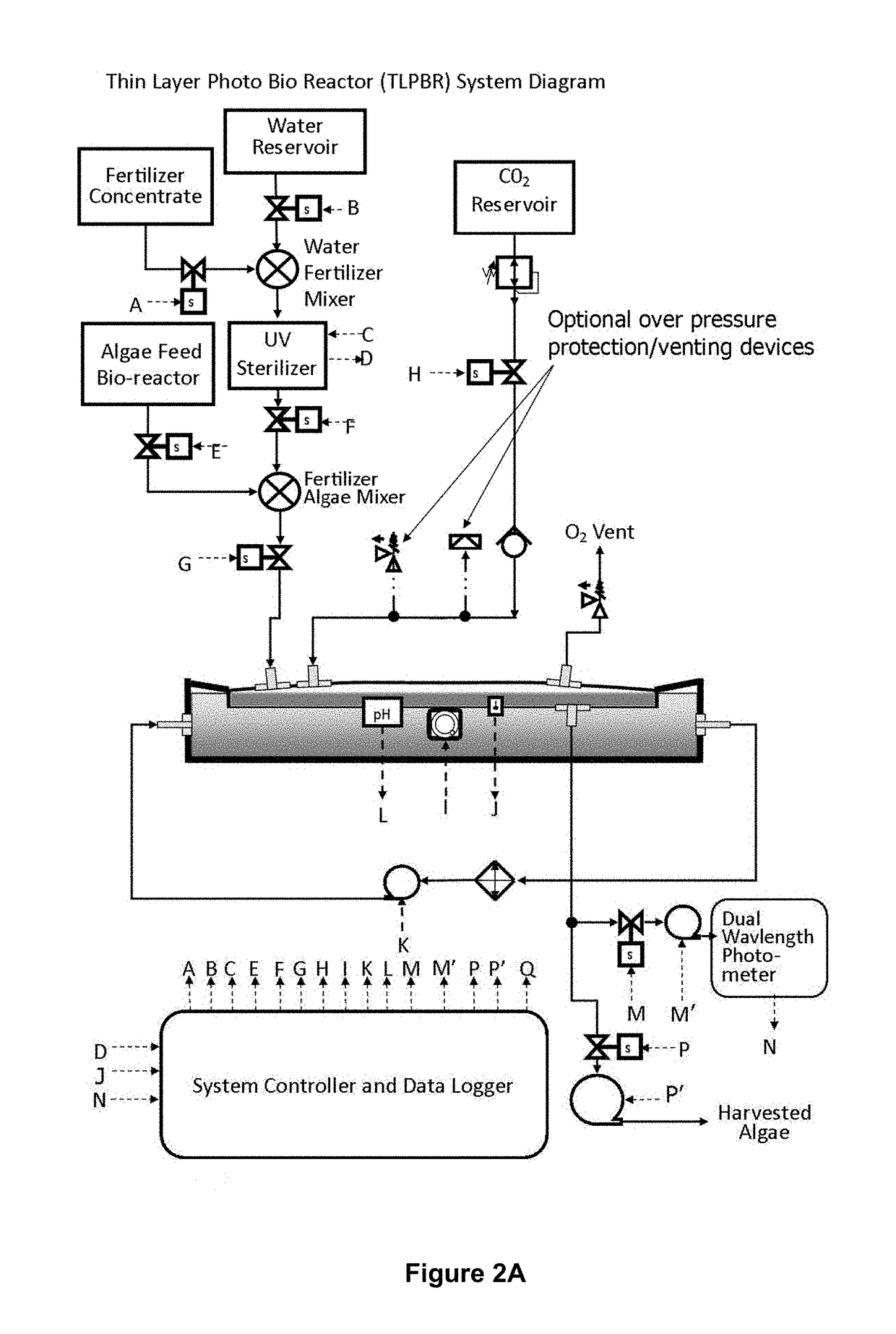

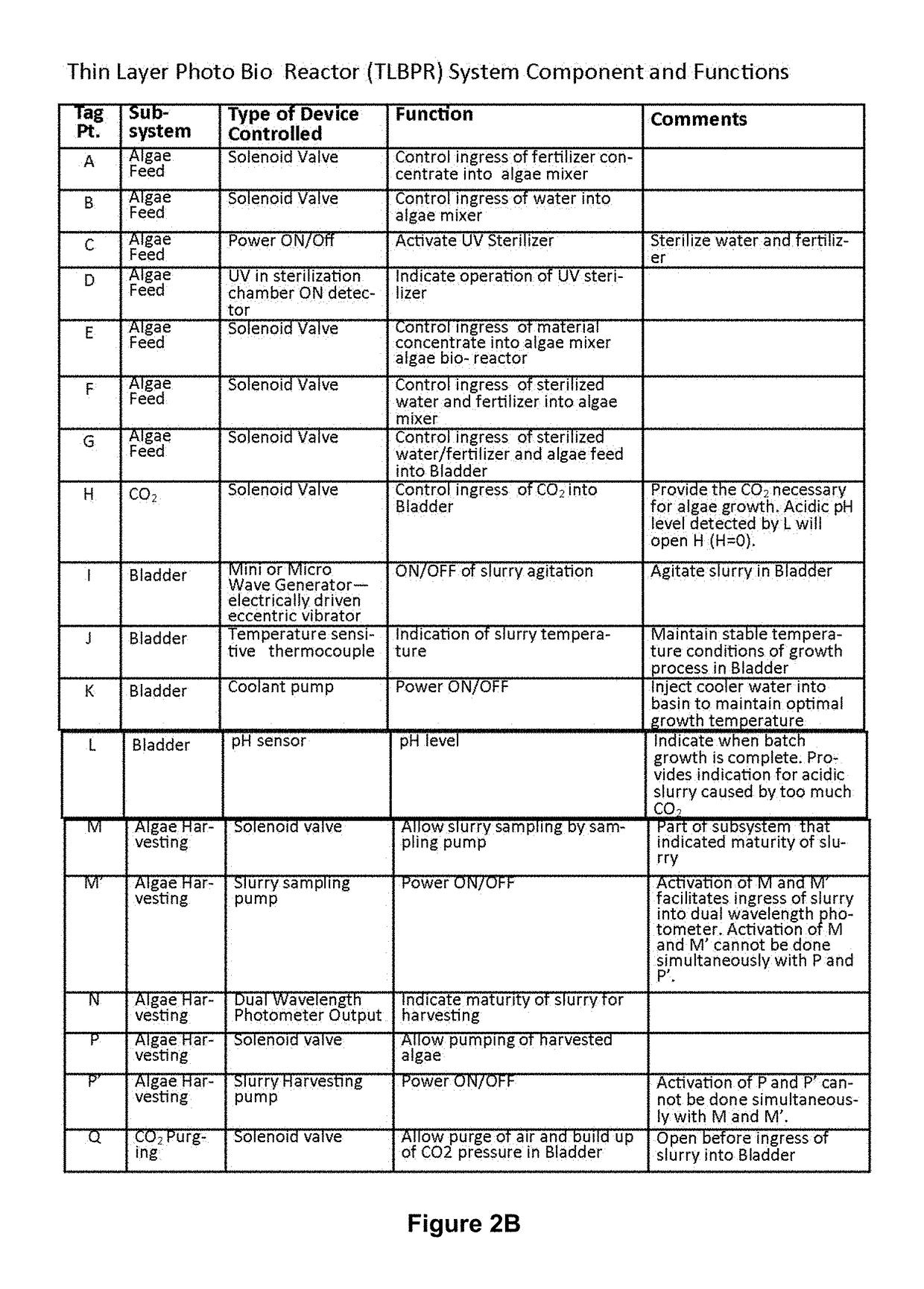

Photobioreactor for enclosed horizontal cultivation of microalgae

ActiveUS9938492B2Large permeabilityLess or impermeable toBioreactor/fermenter combinationsBiological substance pretreatmentsBiological bodyThin layer

A photobioreactor comprising a sealed, covered plastic sheeting coated with a thin layer of a highly dense culture of photoautotrophic single celled organism. Carbon dioxide is exchanged from a gas space above the culture through attendant mixing by subtending wave motion. The photobioreactor provides a substantial improvement in processing costs in growth media sterilization as well as reduced expenses related to energy and raw materials, especially carbon dioxide. Capital expenses are reduced by eliminating the need for sparging and compressors for suspending cells and mixing carbon dioxide.

Owner:GRESSEL JONATHAN +1

Machining technology for low-carbon alloy steel drum brakes

The invention discloses a machining technology for low-carbon alloy steel drum brakes and relates to the technical field of automobile spare parts. The machining technology sequentially comprises the steps of blanking, pre-bending, plate rolling, welding, bending, flat upsetting, reshaping, turning and drilling. According to the machining technology, in the aspect of the cost of machining equipment, by adopting an oil press, the cost is far lower than that of existing centrifugal casting or suspended pressing machines; the utilization rate of material is increased by more than 30% and is far higher than that of traditional manufacturing methods; machined products are protected against cracks on actual working conditions, and the safety is guaranteed; the manufacturing cost is greatly lowered, is lower than the preparation cost of cast iron drum brakes by more than 30% and is lower than the manufacturing cost of thermometal drum brakes by more than 50%.

Owner:绵阳市联重科技有限公司

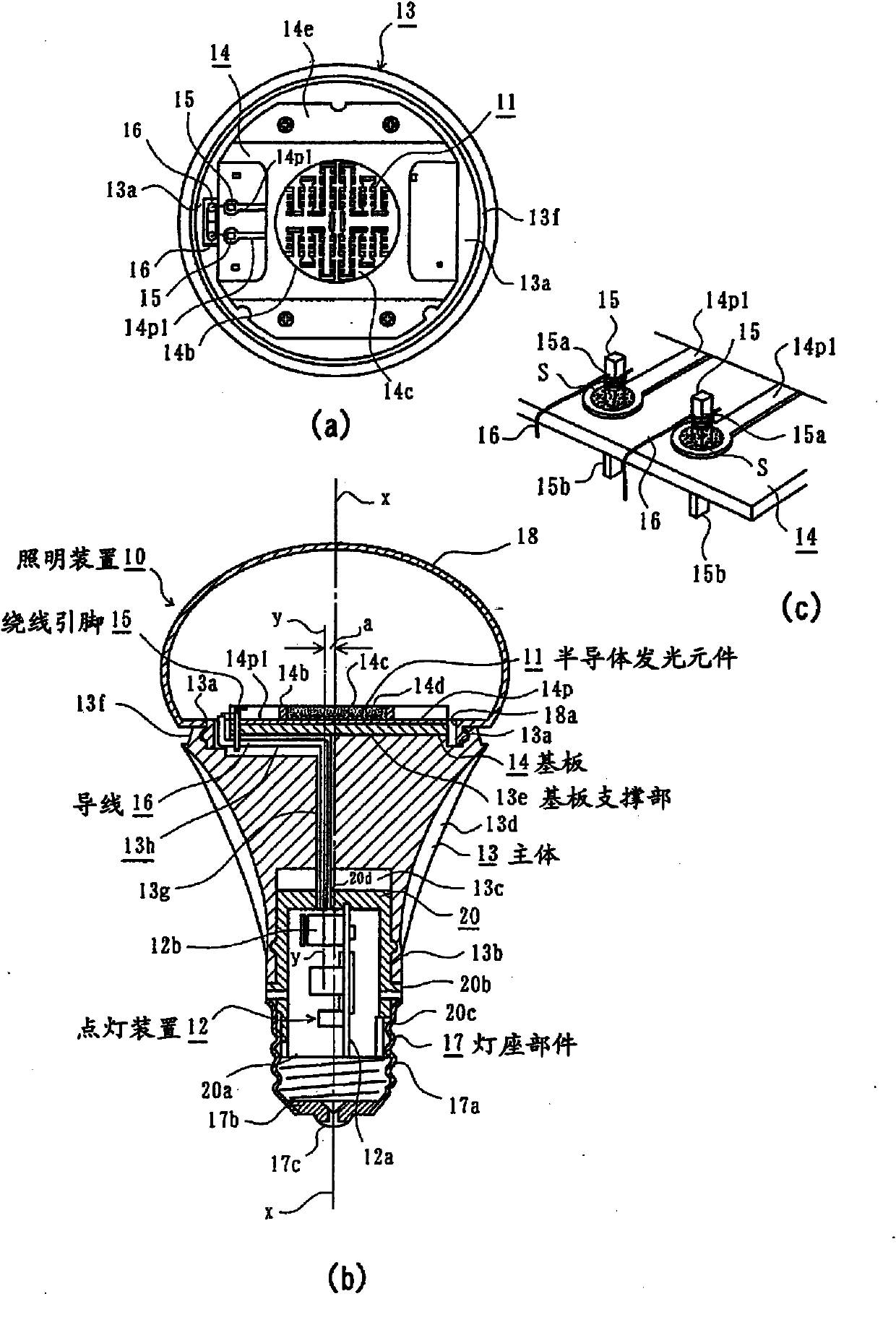

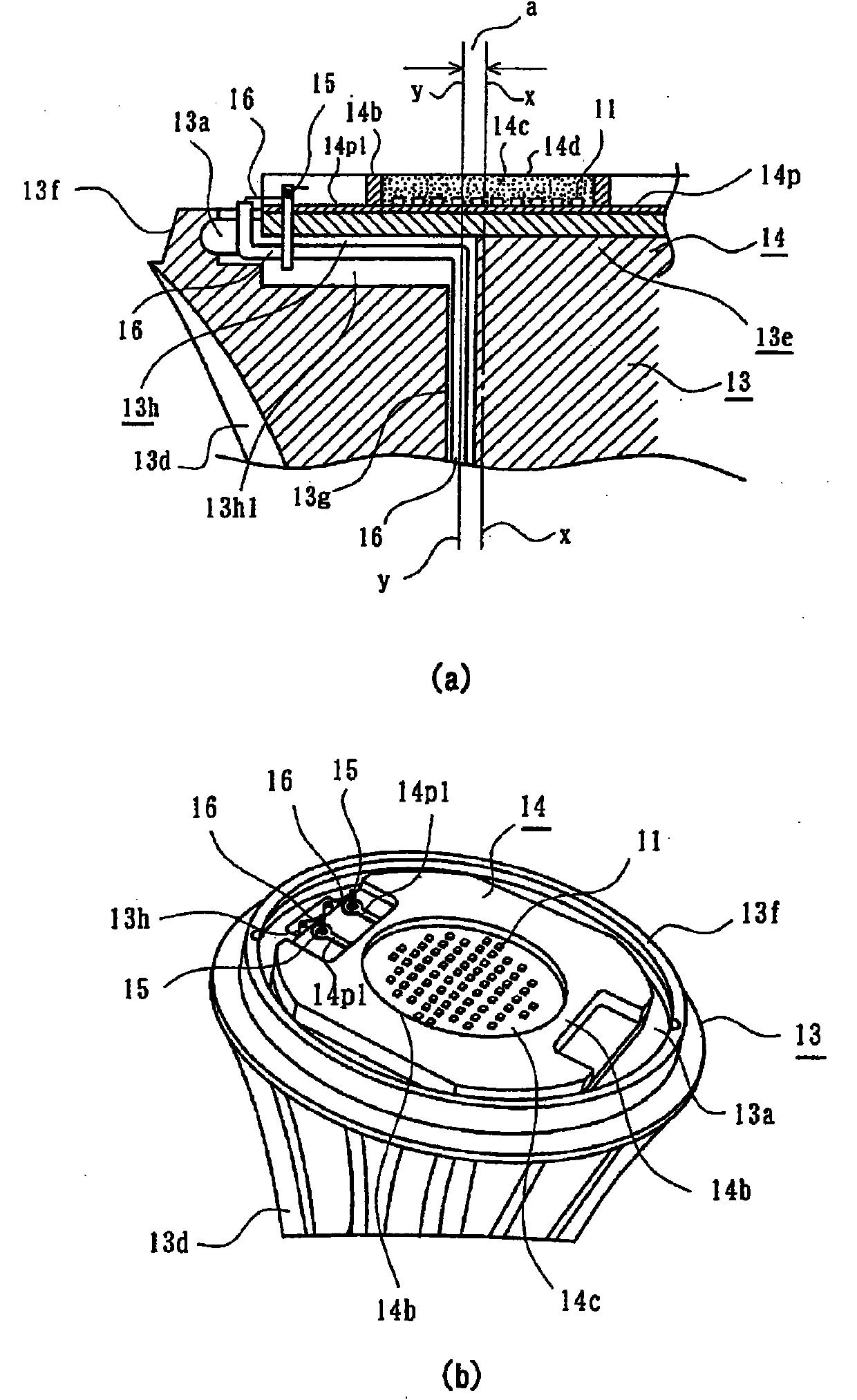

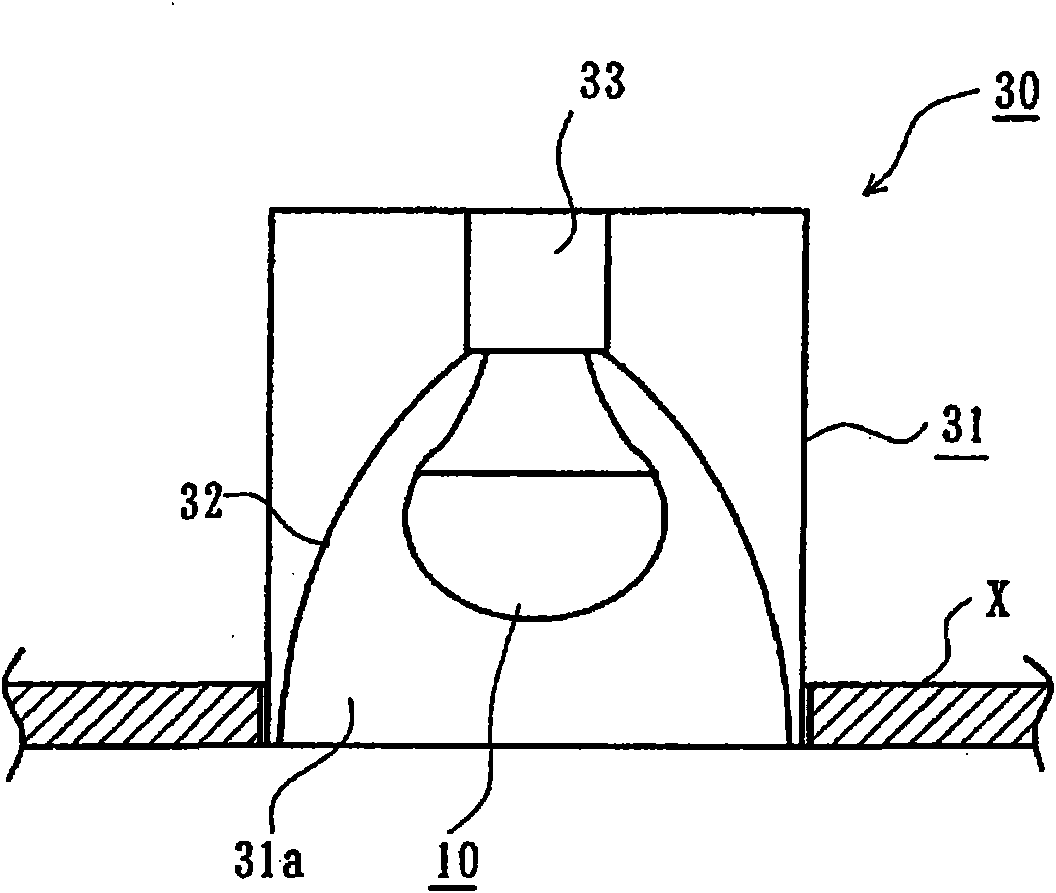

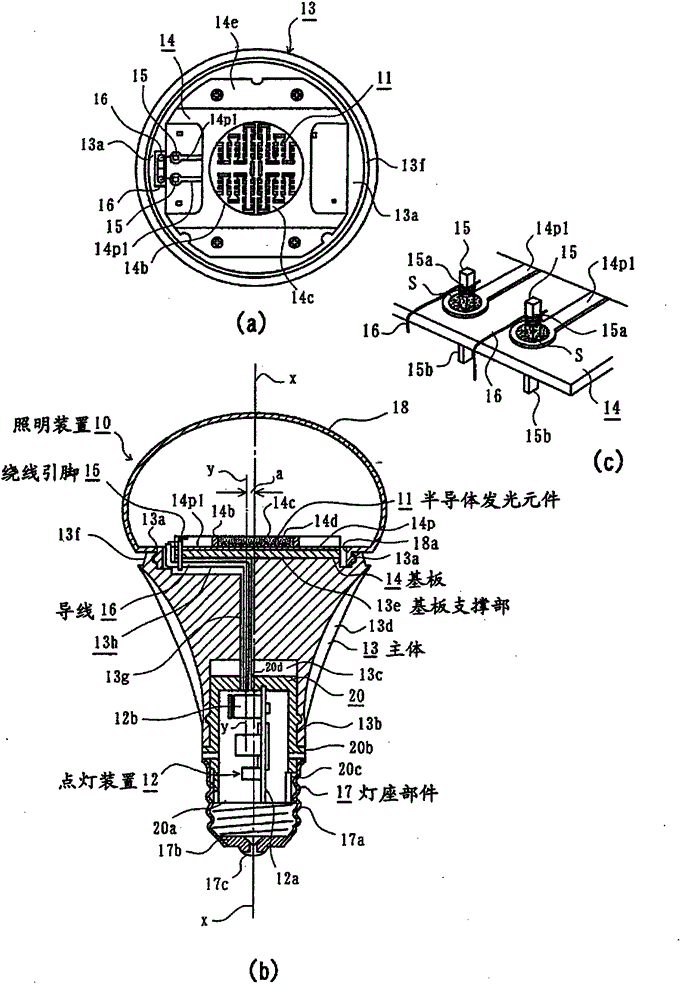

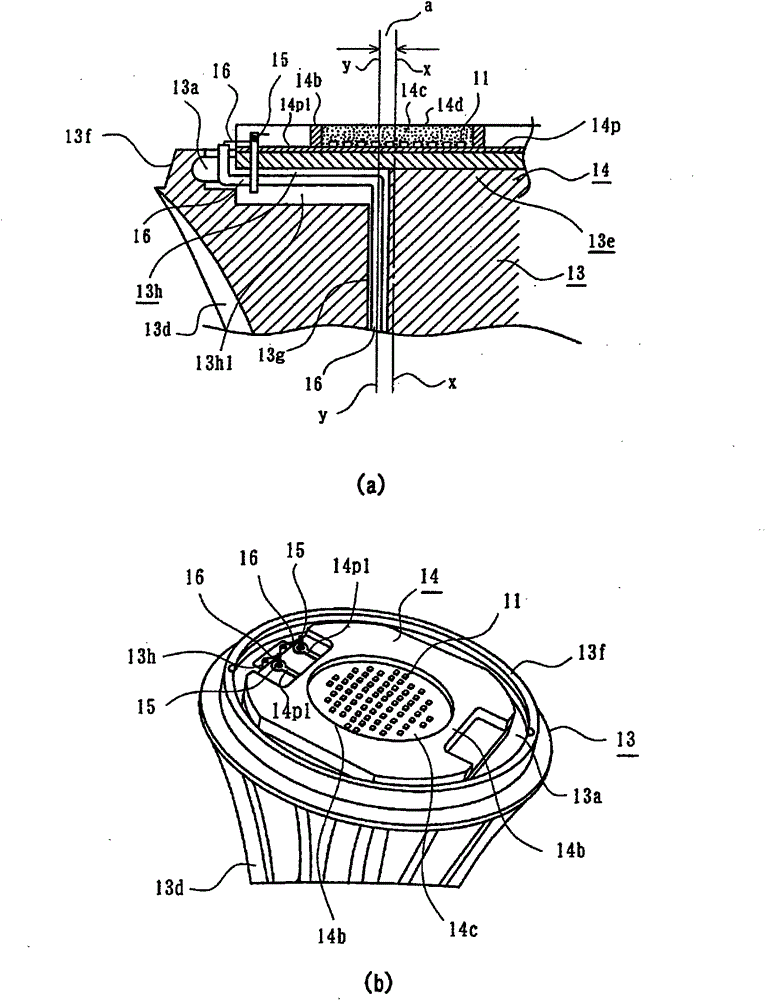

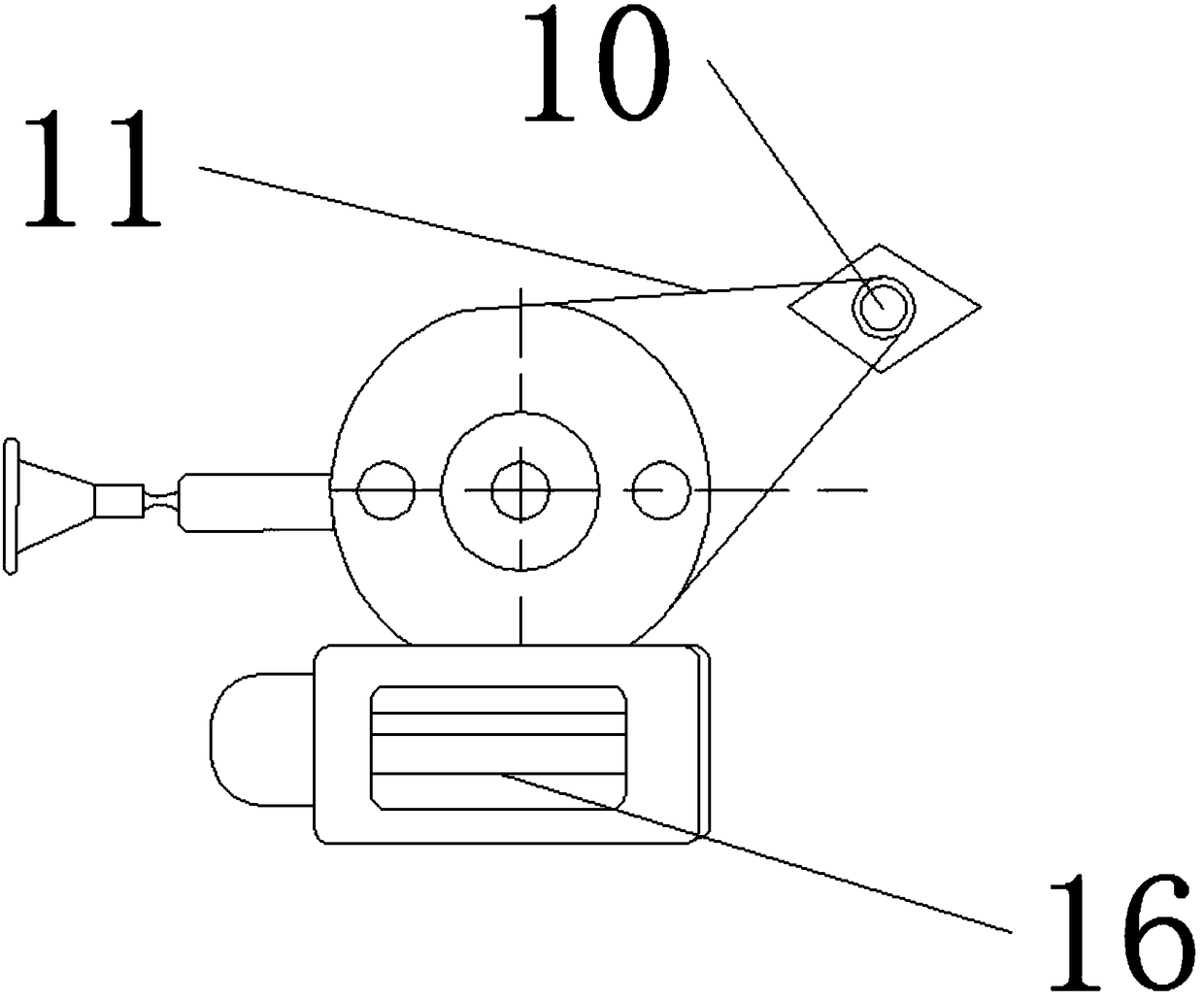

Lighting device and lighting tool

InactiveCN102003666ACost containmentCost advantageElectric circuit arrangementsLighting heating/cooling arrangementsEffect lightEngineering

The invention relates to a lighting device and a lighting tool. A semiconductor light-emitting element favorable for the cost aspect is used as the light source. The lighting device (10) comprises a thermal-conductive main body (13) with a substrate support part (13e) at one end; a substrate (14) provided with the semiconductor light-emitting element (11) and arranged on the substrate support part of the main body; a conductive wire-winding pin (15) arranged on the substrate and connected with the semiconductor light-emitting element (11); a lighting device (12) housed in the main body and lighting the semiconductor light-emitting element; a conductor for power supply (16) with one end connected with the lighting device and another end winded and connected with the wire-winding pin; a light seat part (17) arranged at another end side of the main body and connected with the lighting device. The lighting tool comprises a tool main body with a socket and the lighting device mounted on the socket of the main body. The cost is effectively reduced.

Owner:TOSHIBA LIGHTING & TECH CORP +1

A method for reducing biuret content in industrial urea

ActiveCN105237439BReduce solubilityEasy to implementUrea derivatives preparationOrganic compound preparationChemical industryAnhydrous ethanol

The invention belongs to the field of chemical industry and provides a method for reducing the content of biuret in industrial urea. Use industrial urea as raw material, anhydrous methanol or ethanol as extraction agent, add extraction agent to the raw material; extract under continuous stirring condition, extraction temperature is 20-50°C, extraction time is 1-10h, extraction temperature difference is 3 ~10°C; suction filtration, room temperature drying to constant weight, the purified urea is obtained; the biuret content in the industrial urea is 0.86%-0.94%; the whole system of the present invention is simple and easy to implement, with simple equipment , Low cost advantage. The invention adopts the hot alcohol extractant to treat the biuret, and has the characteristics of energy saving and environmental protection compared with the heating method and the degradation method. Due to the use of industrial urea, the present invention has advantages in terms of material supply and cost.

Owner:DALIAN UNIV OF TECH

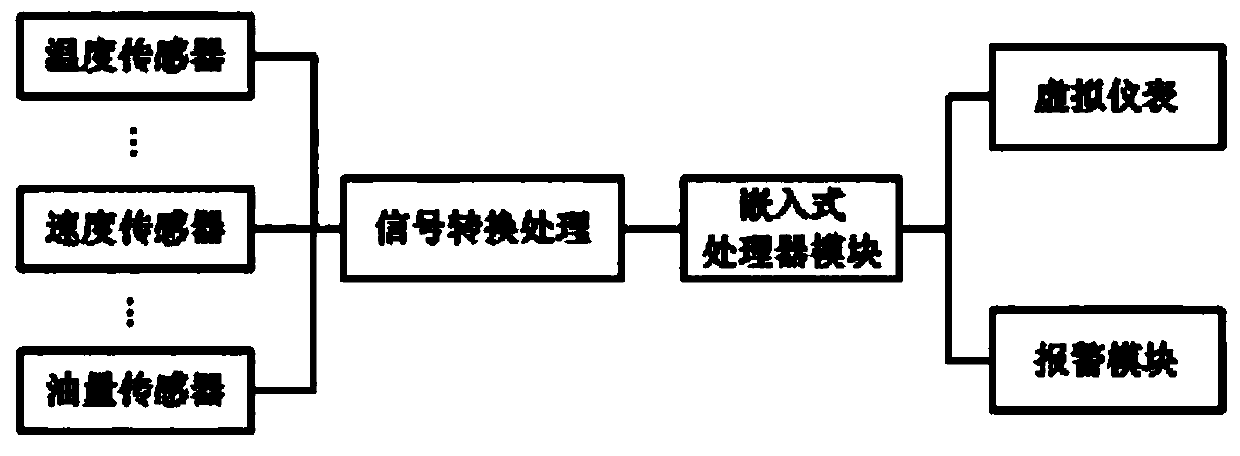

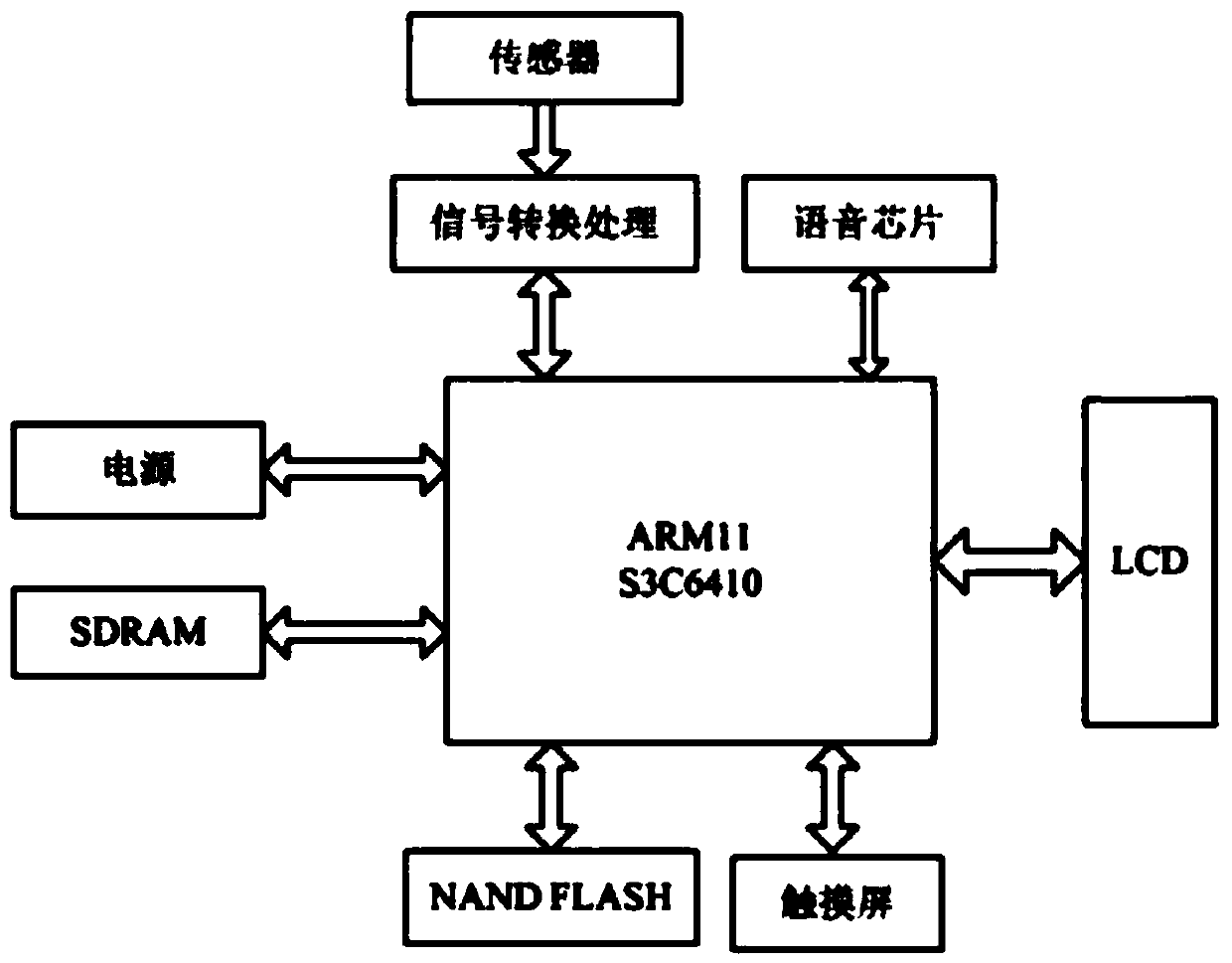

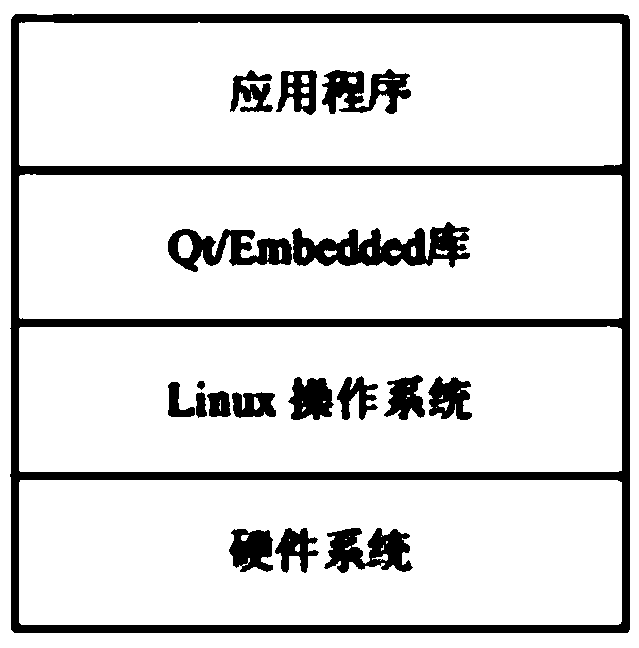

Automobile virtual instrument based on embedded Linux

InactiveCN110576744AImprove readabilityImprove reading accuracyElectric/fluid circuitSoftware systemMaintainability

The invention relates to the technical field of automobile instruments, and provides an automobile virtual instrument based on embedded Linux. The automobile virtual instrument comprises a signal acquisition unit, an embedded processor, a virtual instrument and an alarm module, wherein the signal acquisition unit acquires all kinds of state information of an automobile, the state information is transmitted to the embedded processor through a conversion processing module, the virtual instrument dynamically displays the processed data by adopting a QT design soft panel, the alarm module is usedfor giving a prompt alarm when any one abnormal state exists, the alarm module is internally provided with a voice chip, and the virtual instrument is composed of a hardware system and a software system. The virtual instrument has good readability, high reading precision, good improvement in portability, maintainability and cost aspects, and great scientific research value and commercial use value.

Owner:上海新围电子科技有限公司

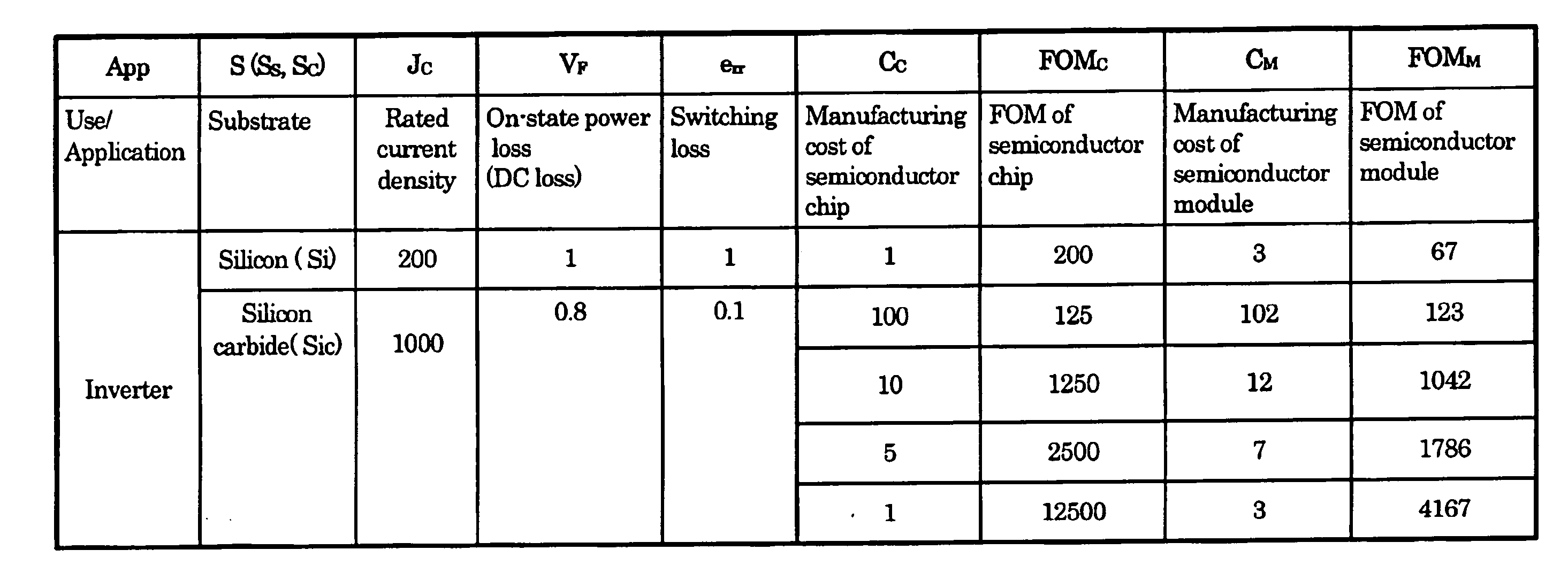

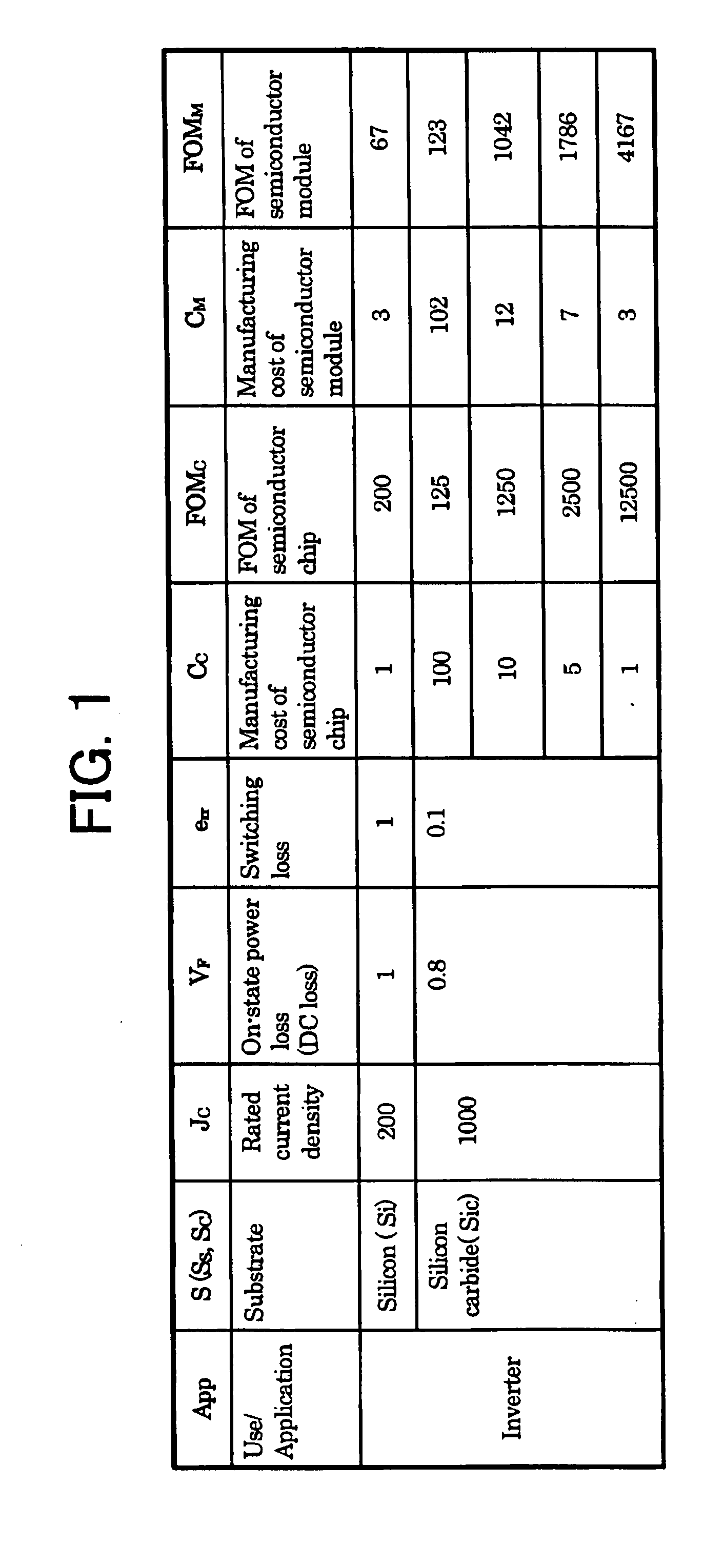

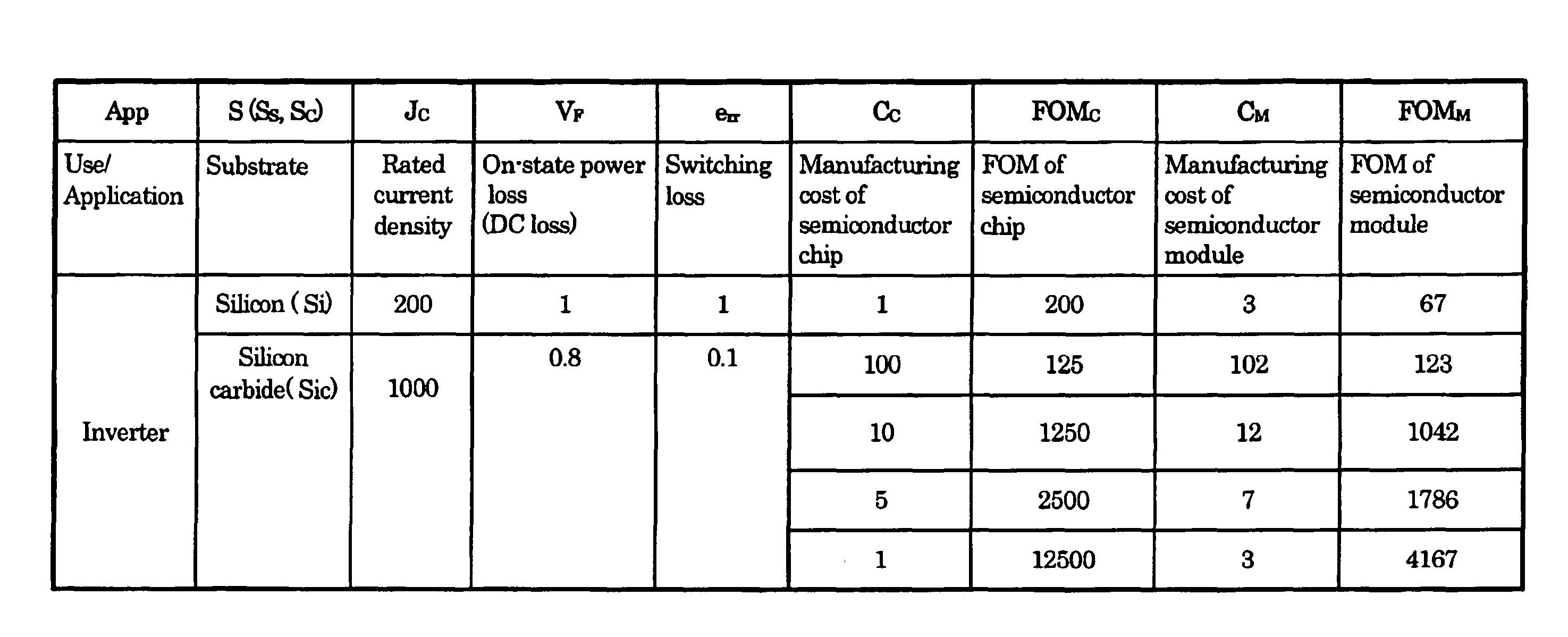

Method of manufacturing semiconductor chip and semiconductor module

ActiveUS20100075444A1Cost productionSatisfying electrical performanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductor chipElectrical performance

An FOM (figure of merit) enabling evaluation from a cost aspect, as well as evaluation of electrical performance, is newly proposed to provide a method of manufacturing based on the FOM a semiconductor chip intended for a lower cost production in addition to satisfying electrical performance. An FOMC of a semiconductor chip is defined as the product of a term represented by electrical performance of a substrate S and a term represented by a semiconductor chip cost CC; the FOMC of each of the semiconductor chips on substrates SS, SC of different type is determined by calculation of the product thereof. Based on the magnitudes of the calculation results, a desired substrate is selected from the substrates SS, SC and then a semiconductor chip is fabricated by forming a semiconductor element on the desired substrate selected.

Owner:MITSUBISHI ELECTRIC CORP

Method of manufacturing semiconductor chip and semiconductor module

ActiveUS7989227B2Low costSatisfactory performanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

An FOM (figure of merit) enabling evaluation from a cost aspect, as well as evaluation of electrical performance, is newly proposed to provide a method of manufacturing based on the FOM a semiconductor chip intended for a lower cost production in addition to satisfying electrical performance. An FOMC of a semiconductor chip is defined as the product of a term represented by electrical performance of a substrate S and a term represented by a semiconductor chip cost CC; the FOMC of each of the semiconductor chips on substrates SS, SC of different type is determined by calculation of the product thereof. Based on the magnitudes of the calculation results, a desired substrate is selected from the substrates SS, SC and then a semiconductor chip is fabricated by forming a semiconductor element on the desired substrate selected.

Owner:MITSUBISHI ELECTRIC CORP

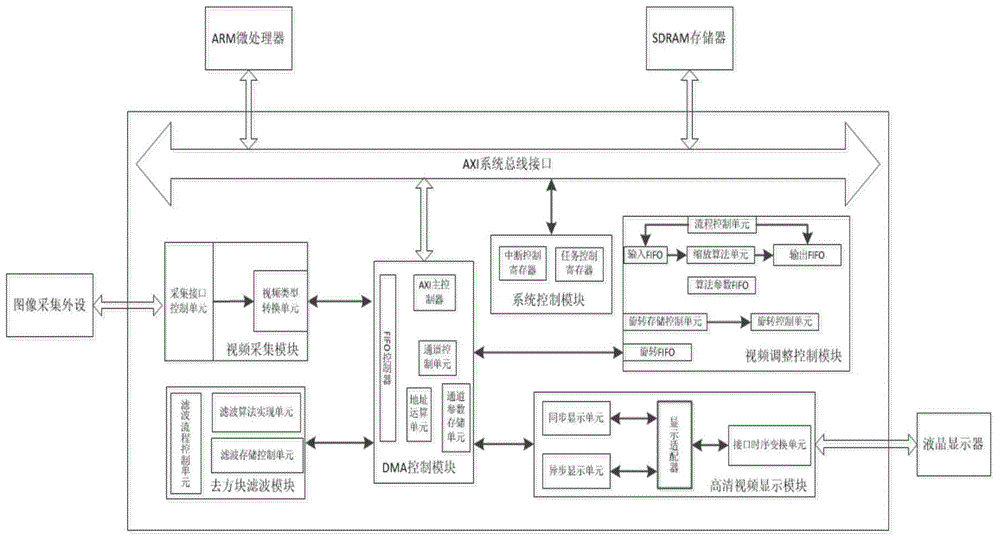

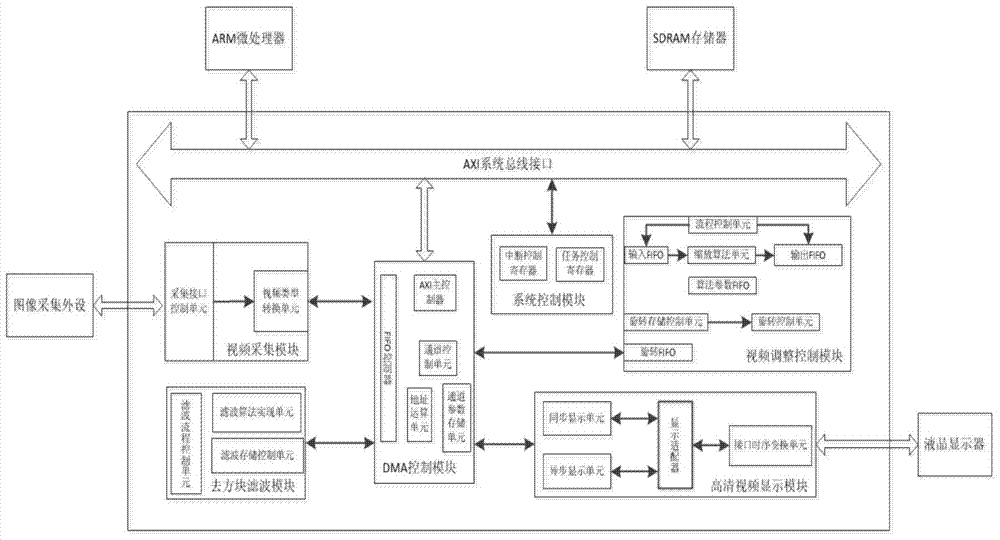

Framework of high-definition video processing unit

ActiveCN104023202ARealize the designed functionImprove operational efficiencyClosed circuit television systemsFiltrationBus interface

The invention relates to a framework of a high-definition video processing unit. The framework comprises the high-definition video processing unit, an image acquisition peripheral, a liquid crystal displayer, an ARM microprocessor, an SDRAM memory, and an AXI system bus interface connected with an image acquisition interface of the image acquisition peripheral and a liquid crystal displayer display interface as well as connected with the ARM microprocessor and the SDRAM memory . The high-definition video processing unit comprises a video processing module, a desquaring filtration module, a DMA control module, a system control module, a video adjustment control module and a high-definition display module. Different parts of the same type of chips can be selected to use according to the demands of different users, thereby meeting the demands of the majority of users well and solving the problem of functional requirements of the majority of users through reasonable configuration of a type of chips; and for the cost aspect, the design cost of a plurality of electronic products can be greatly reduced, so that the design is allowed to have better competitive edge, and the framework has wide application values.

Owner:SHANDONG UNIV

Polarization plate sheet warping correcting method

The invention provides a polarization plate sheet warping correcting method. According to the method, a polarization plate sheet is placed in a cylinder, then, the polarization plate sheet and the cylinder are placed in the conditions with the proper environment temperature and temperature, correction is conducted for a certain time, and accordingly a warped NG product is corrected into a qualified product again. The polarization plate sheet warping correcting method overcomes the restraints of site and equipment requirement conditions in the existing technology; the advantage in the cost aspect is obvious, targeted correction is conducted on the warped NG finished product, and cost waste is reduced; and a correcting tool is simple in structure, the environment required precision is not high, and batched correction can be achieved.

Owner:SHENZHEN SAPO PHOTOELECTRIC

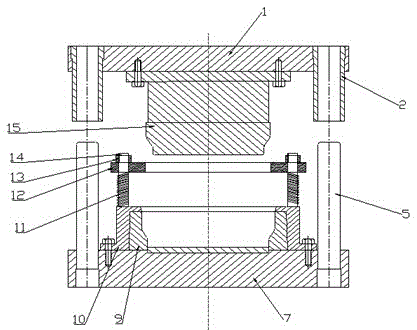

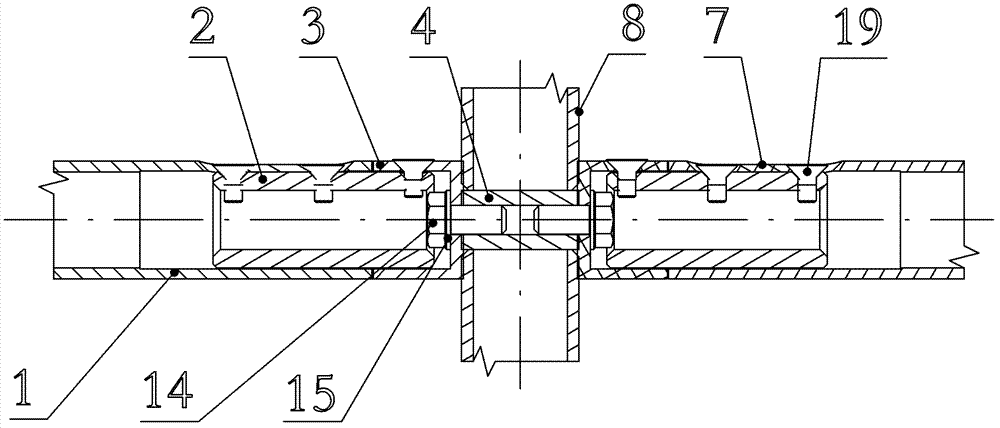

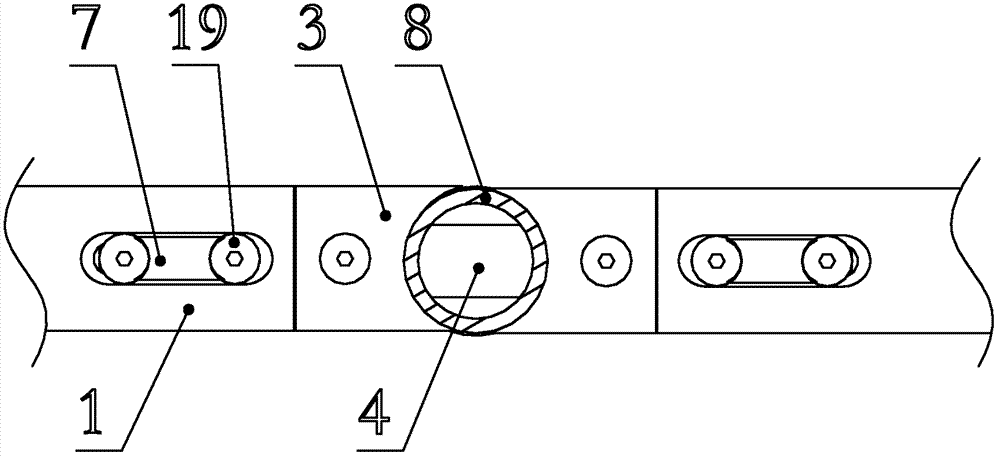

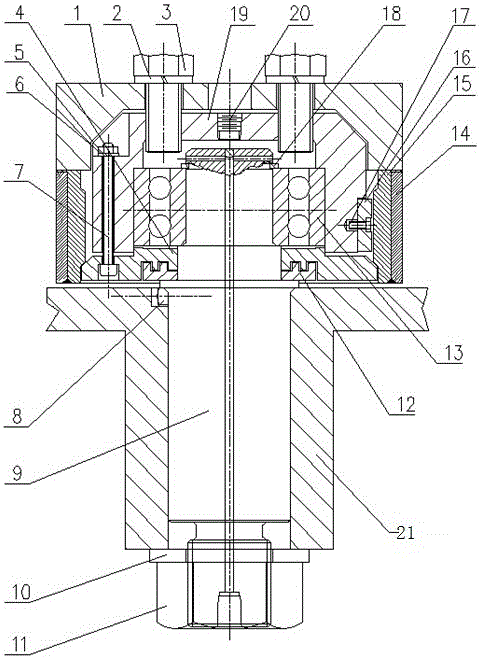

Invisible connecting structure for crossed handrail of rail vehicle

InactiveCN102966648AGuaranteed integrityGuaranteed aestheticsRailway componentsRod connectionsCross connectionEngineering

The invention relates to an invisible connecting structure for a crossed handrail of a rail vehicle. The invisible connecting structure comprises a vertical handrail, a longitudinal handrail, a connecting rod and a connecting shaft, wherein the connecting rod is a round pipe with a screw hole and one sealed end, a threaded sleeve is horizontally arranged in the vertical handrail, the connecting rod is horizontally and fixedly arranged at the side surface of the vertical handrail through a hexagon bolt and the threaded sleeve, and the connecting rod and the longitudinal handrail are sheathed on the connecting shaft and are respectively fixed with the connecting shaft through sunk screws, so the connecting rod and the longitudinal handrail are fixed into a whole. The connecting structure has the advantages that the handrail realizes the crossed connection through a transition element and an internal connecting element, a fastening element at the connecting part is fixedly arranged at the upper part which cannot be easily seen by passengers, and the integrity and the attractive appearance of the handrail and the connecting part are ensured in the appearance aspect, wherein the cost of parts adopted at the connecting part of the crossed handrail is low, the processing is easy, the production period is short, and the connecting structure of the existing crossed handrail is greatly improved in the appearance and cost aspects.

Owner:CRRC NANJING PUZHEN CO LTD

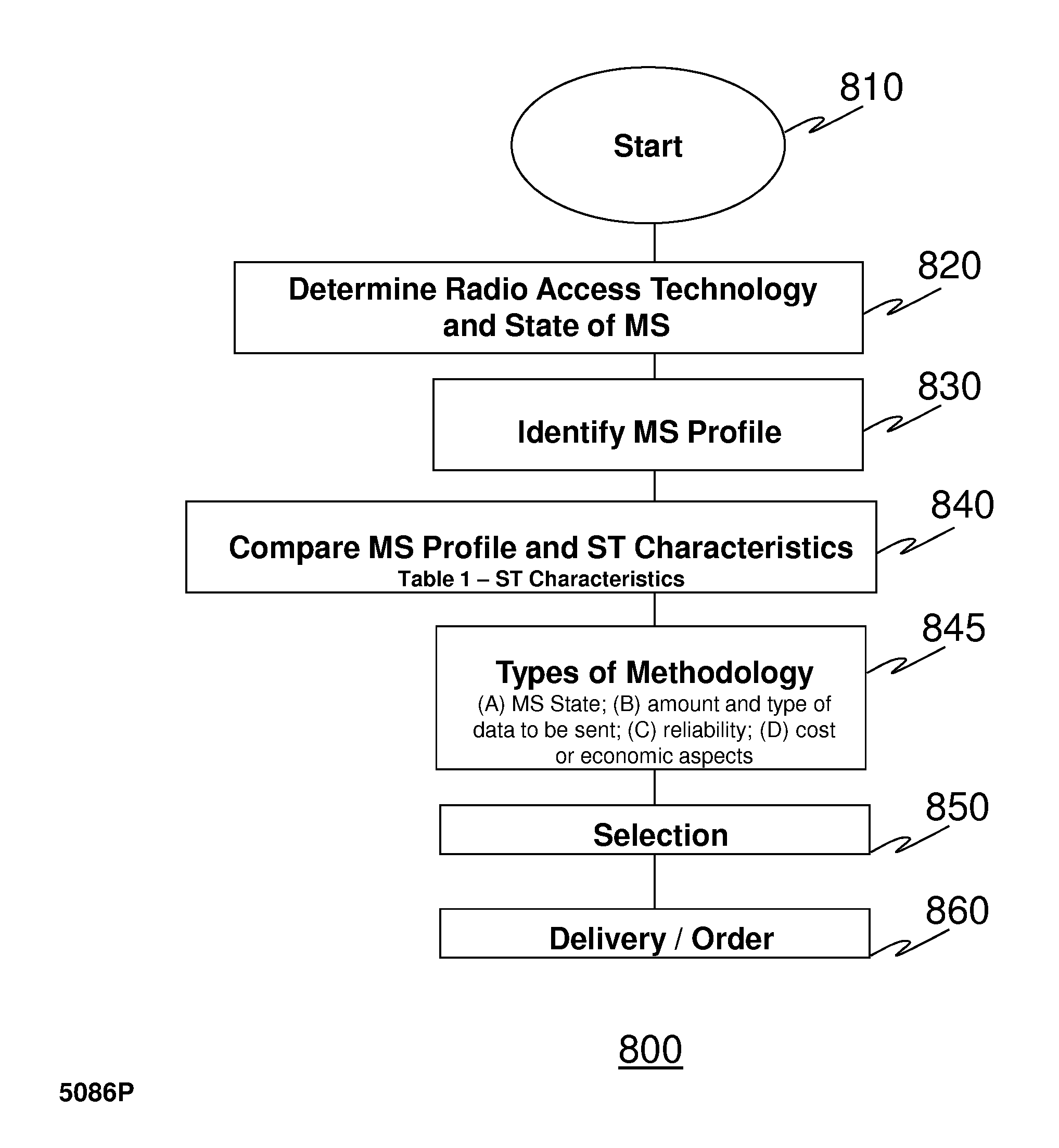

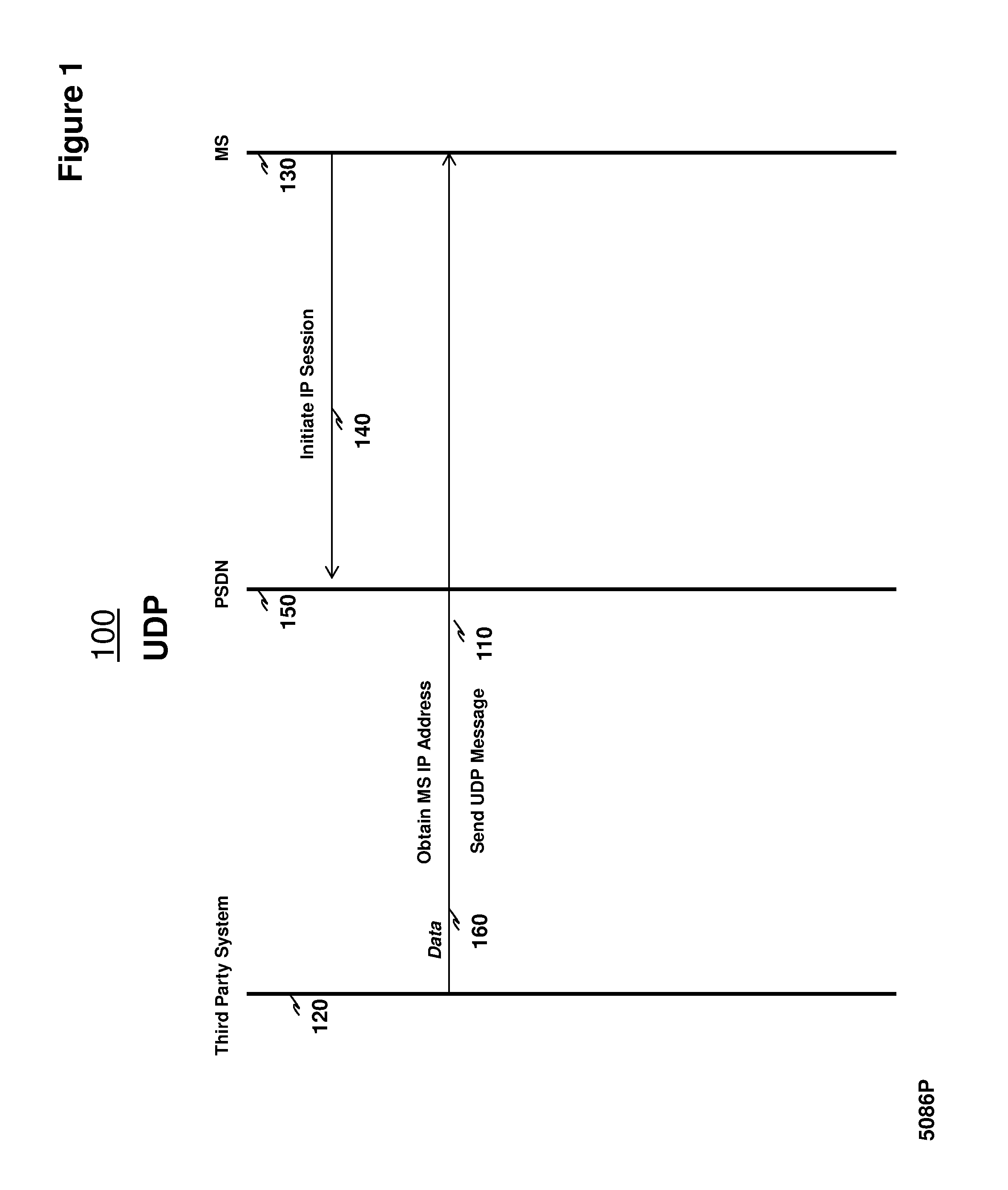

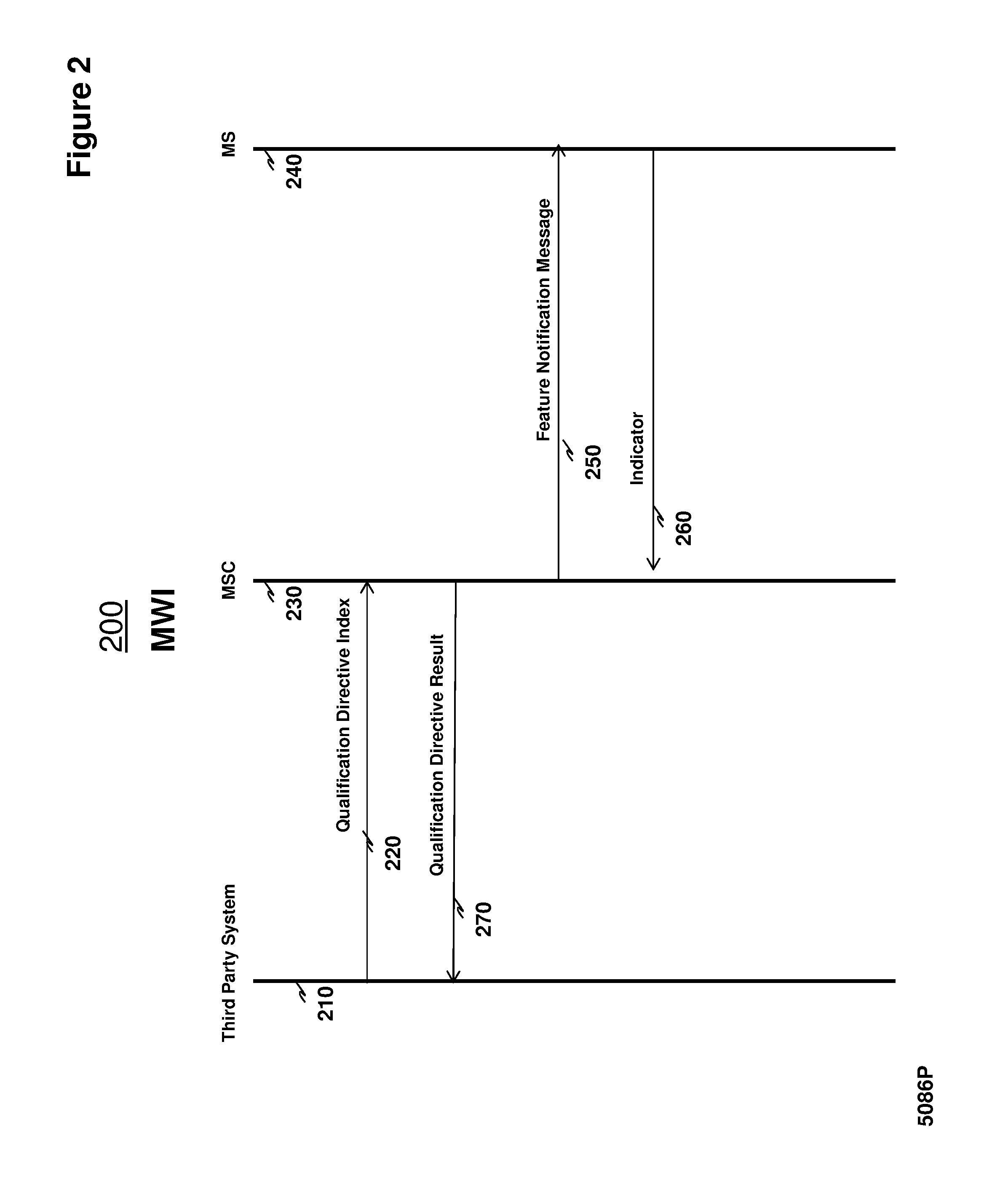

Method to optimize the selection and delivery of a shoulder-tap to a cellular mobile station

Owner:AERIS COMM

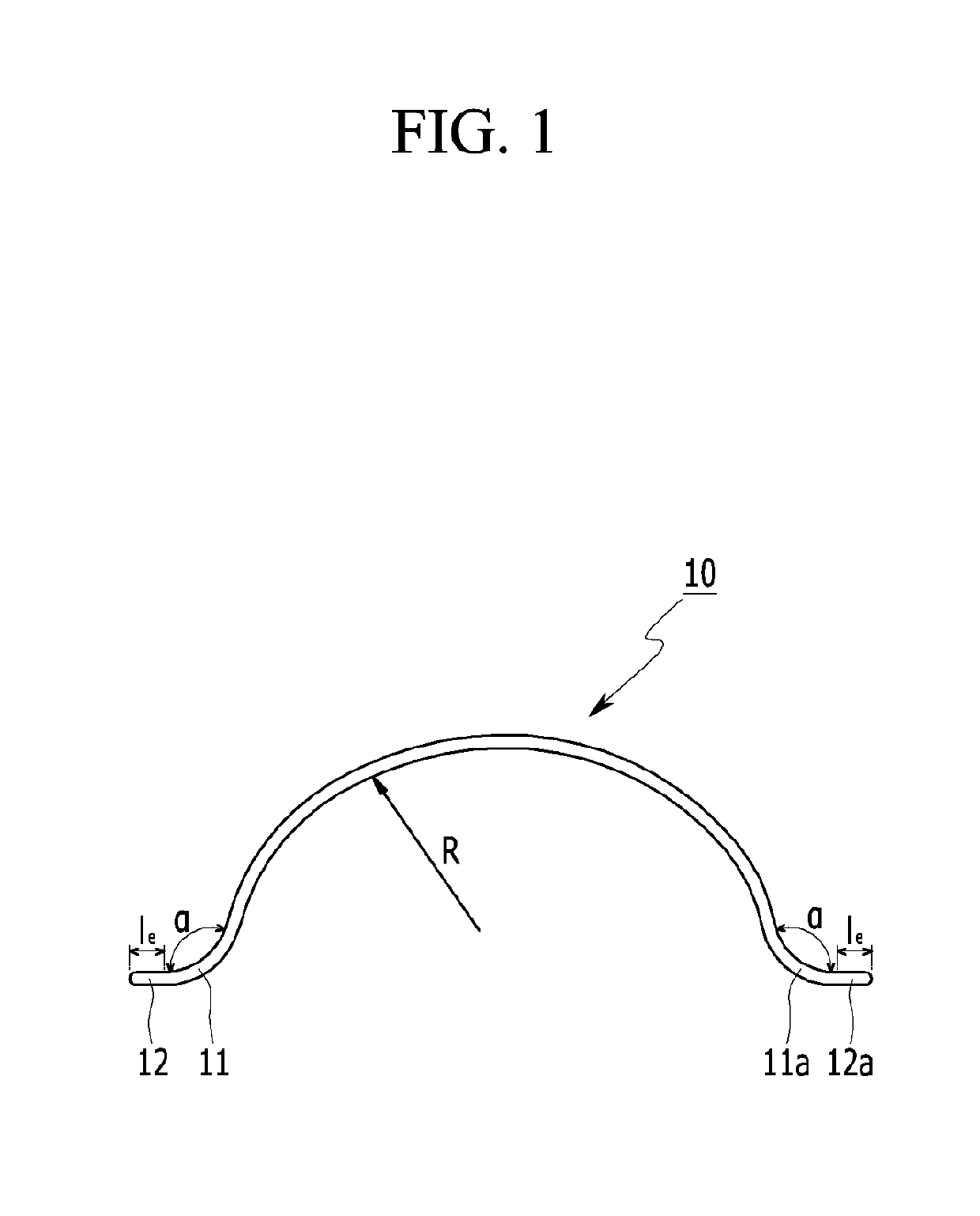

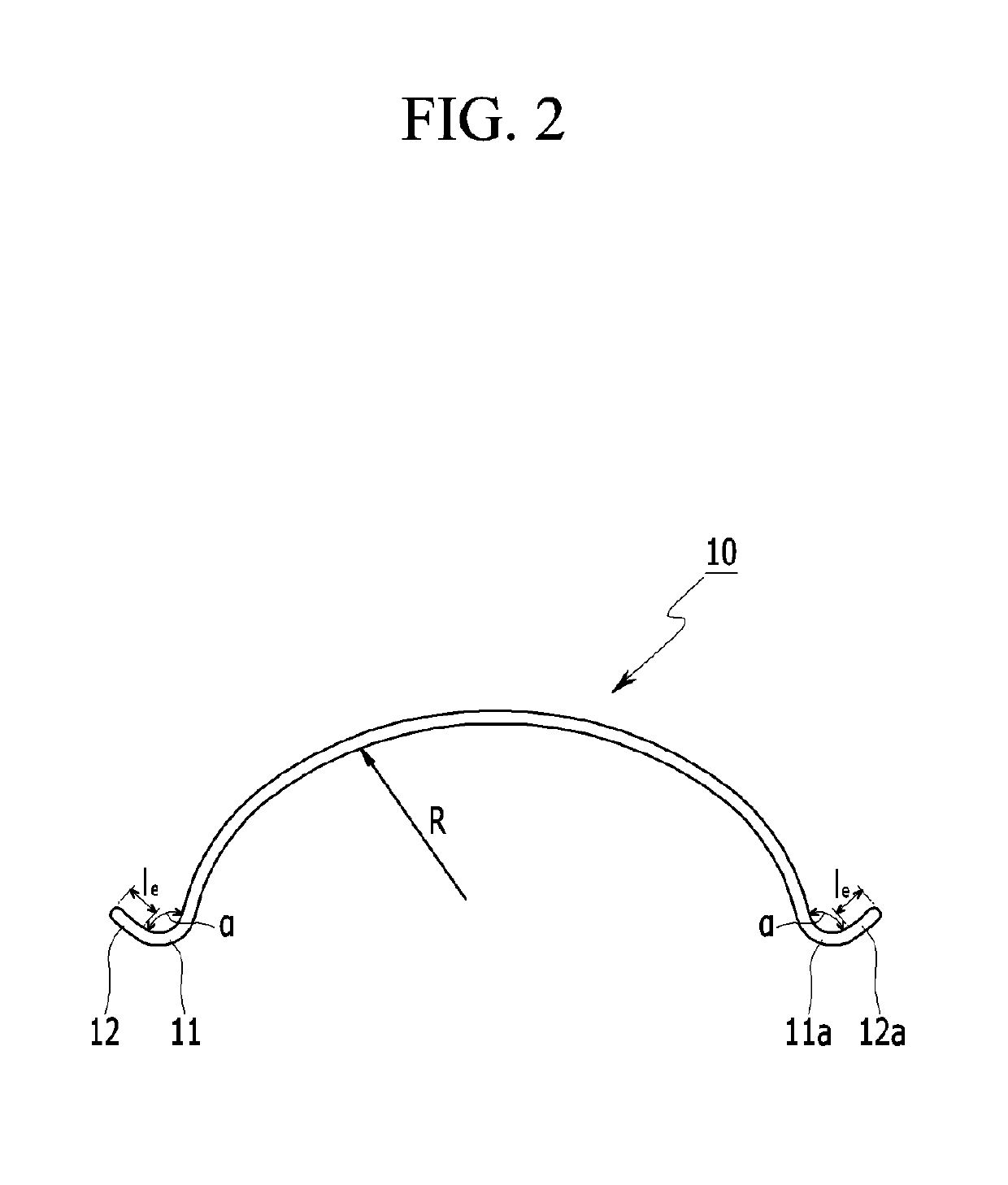

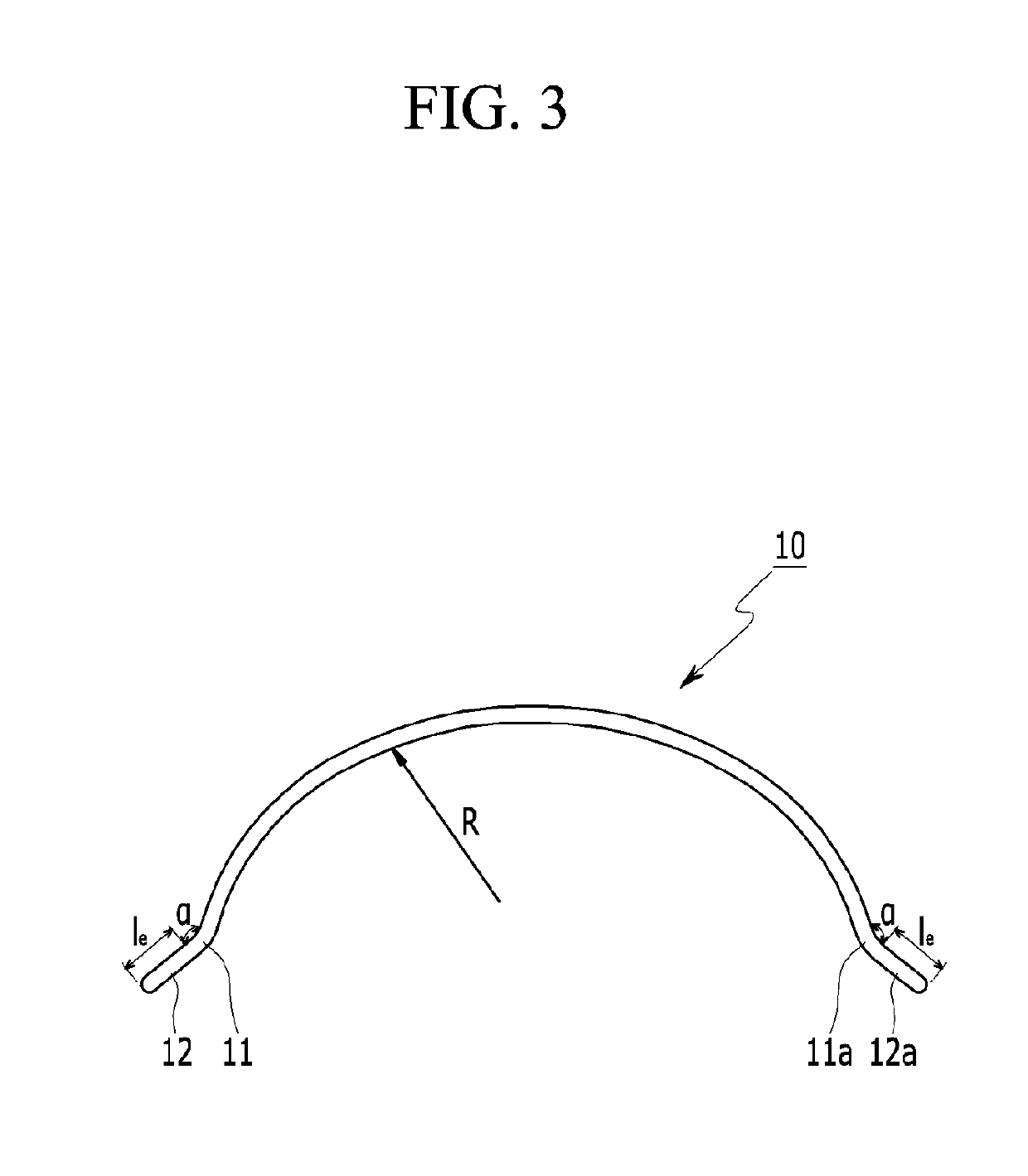

Arched steel fibers for reinforcing cement-based material

ActiveUS10414691B2High strengthMechanical performanceBuilding reinforcementsThin material handlingFiberEnergy absorption

The present invention discloses an arched steel fiber for reinforcement of a cement-based material, of which a main body is arched in a length direction and opposite ends of the main body are curved such that the steel fiber has a higher pullout resistance strength compared to a conventional steel fiber, thereby improving mechanical performance such as a tensile strength, a flexural strength, an energy absorption capability, and the like of a cement compound. In addition, compared to a conventional art, a mixing amount of steel fiber to performance can be reduced so that an added economic value in terms of consumable cost can be created.

Owner:KOSTEEL

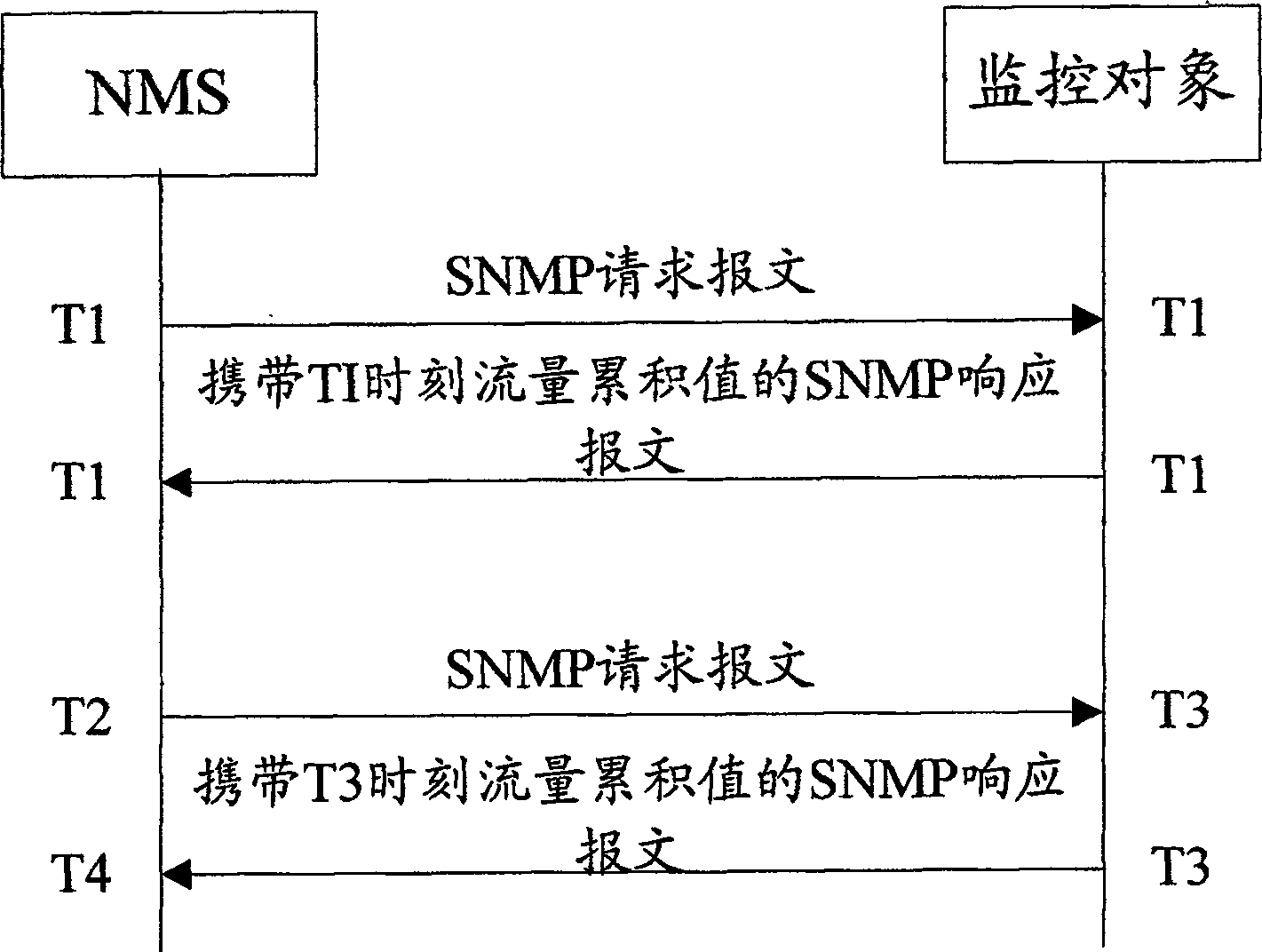

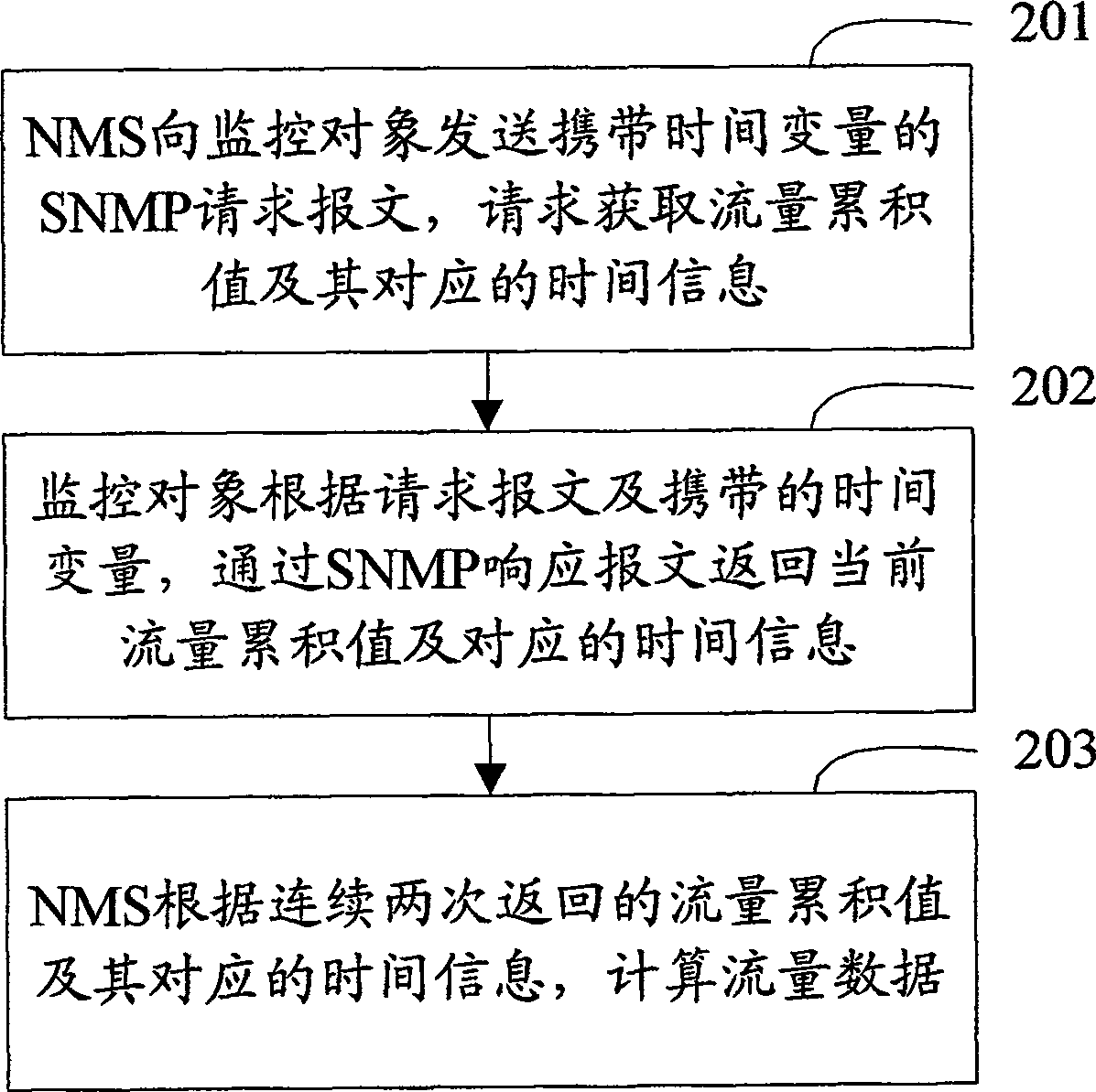

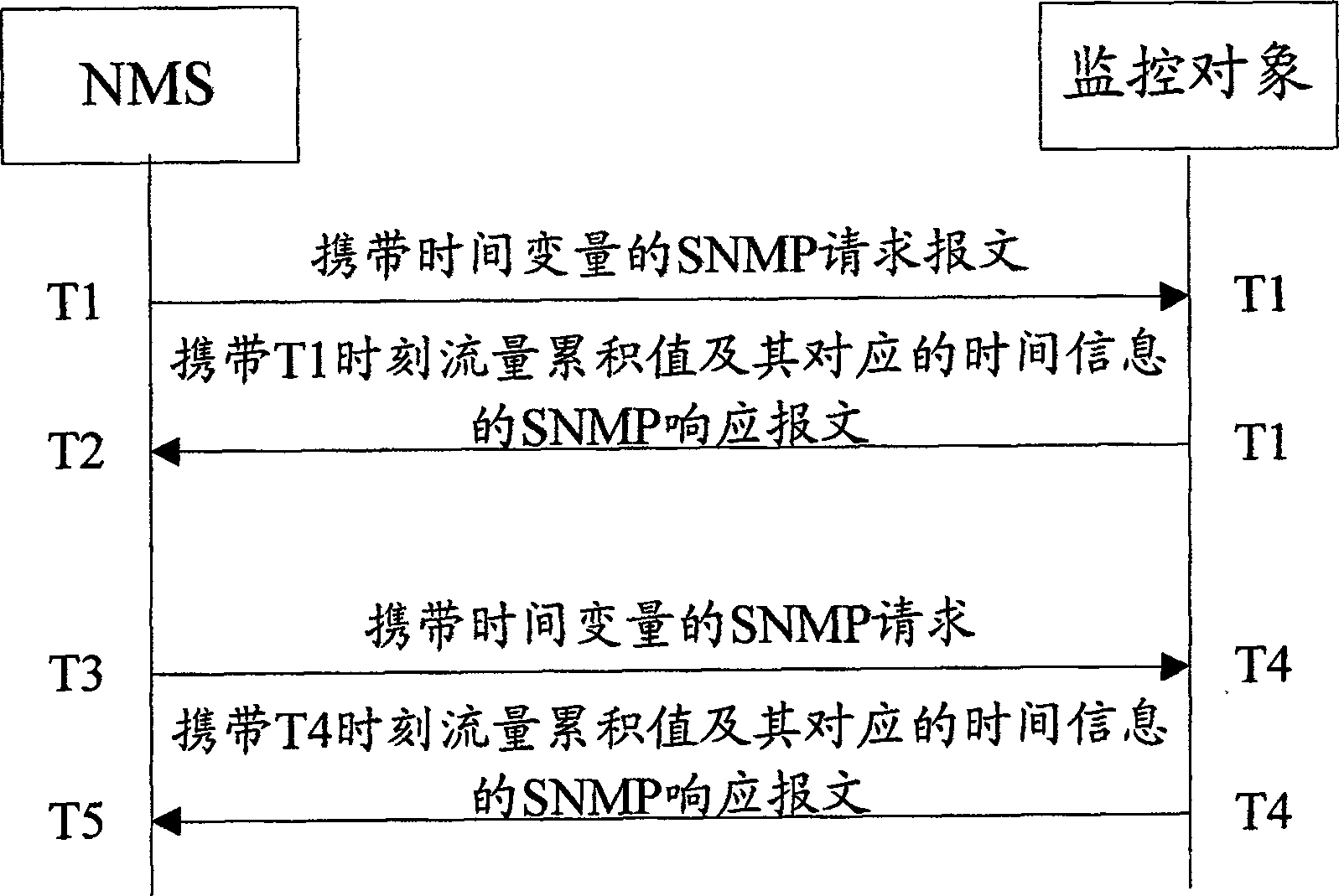

Method and system and device for collecting flow data

ActiveCN100512162CAccurate timeAccurate calculationData switching networksTime informationObject based

The invention discloses a flow data collection method and system, and a flow data collection device. In the present invention, a time variable is added to the request message for obtaining the flow accumulation value, and the monitoring object returns the flow accumulation value and the corresponding time information to the flow data collection device according to the time variable, so that the flow data collection device can know each Accurate time corresponding to each flow accumulation value, and then accurate flow data can be calculated. Moreover, when realizing the technical solution of the present invention based on SNMP, existing variables in SNMP can be used as time variables, so that the technical solution of the present invention can be realized without any improvement to the monitoring objects in the network, and then the cost is reduced. The realization cost of the technical solution of the invention improves the feasibility of the technical solution of the present invention, and makes the technical solution of the present invention have higher practicability.

Owner:NEW H3C TECH CO LTD

A method for photocatalytic synthesis of ammonia

The invention provides a method for synthesizing ammonia through photocatalysis. According to the invention, water is added in a reaction vessel, a catalyst is added in the reaction vessel, a mixture is subjected to ultrasonic mixing, nitrogen is introduced, magnetic stirring is kept, the uniformly stirred mixture is put under illumination condition, a sample is taken, the catalyst is separated, and the concentration of NH4<+> in a solution is analyzed by an indophenol blue spectrophotometry method. The method for synthesizing ammonia through photocatalysis realizes ammonia synthesis under normal temperature and normal pressure, yield can reach as high as 12019.2 grams which is equal to 8289 times of an industrial value standard provided by Schrauzer, and the requirements for industrial production on cost aspect, environmental protection aspect, and technology aspect can be completely satisfied.

Owner:NANJING POLYTECHNIC INSITUTE

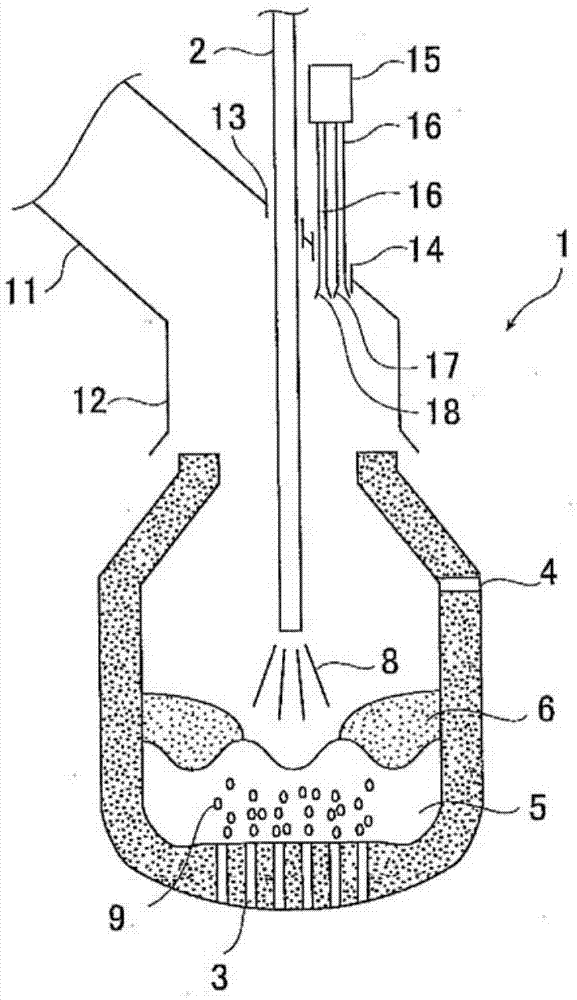

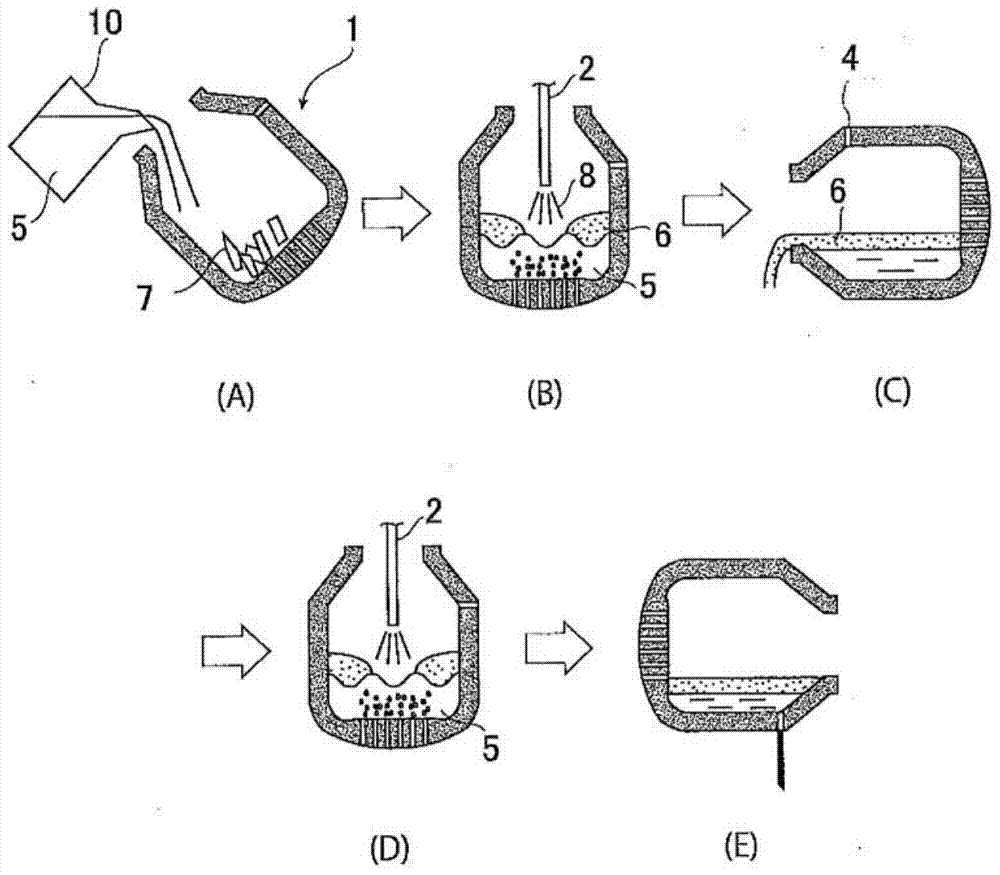

Pretreatment method of molten iron

ActiveCN104955965BReduce phosphorus concentrationSuppression of bump effluxManufacturing convertersPretreatment methodSlag

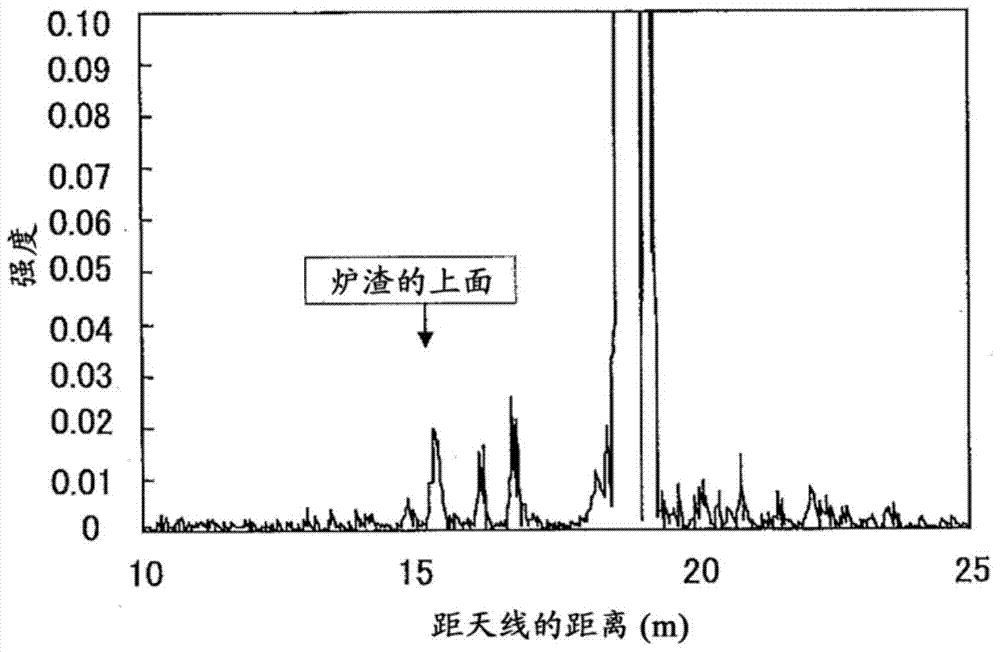

The present invention relates to a method for pretreatment of molten iron, which uses a single converter type refining furnace to continuously perform desiliconization and dephosphorization of molten iron with an intermediate slagging process, in which a sufficient amount of The slag is quickly discharged out of the furnace, and sufficient dephosphorization treatment can be performed in terms of cost and quality. The pretreatment method of the present invention includes: a desiliconization treatment process, supplying a gaseous oxygen source to the molten iron (5) in the converter type refining furnace (1) from a top blowing lance (2) to desiliconize the molten iron; a slagging process, At least a part of the slag generated in the desiliconization process is discharged from the converter type refining furnace; in the dephosphorization process, after the slagging process, a CaO-based flux is added to the converter type refining furnace, and a gaseous oxygen source is supplied from the top blowing lance , dephosphorize the remaining molten iron, wherein, in the desiliconization process, the slag height in the furnace is measured, and the measured slag height is defined by the distance from the molten iron bath surface in the furnace to the furnace mouth The desiliconization process is completed in a state where the height ratio of the melting chamber in the furnace is in a predetermined range.

Owner:JFE STEEL CORP

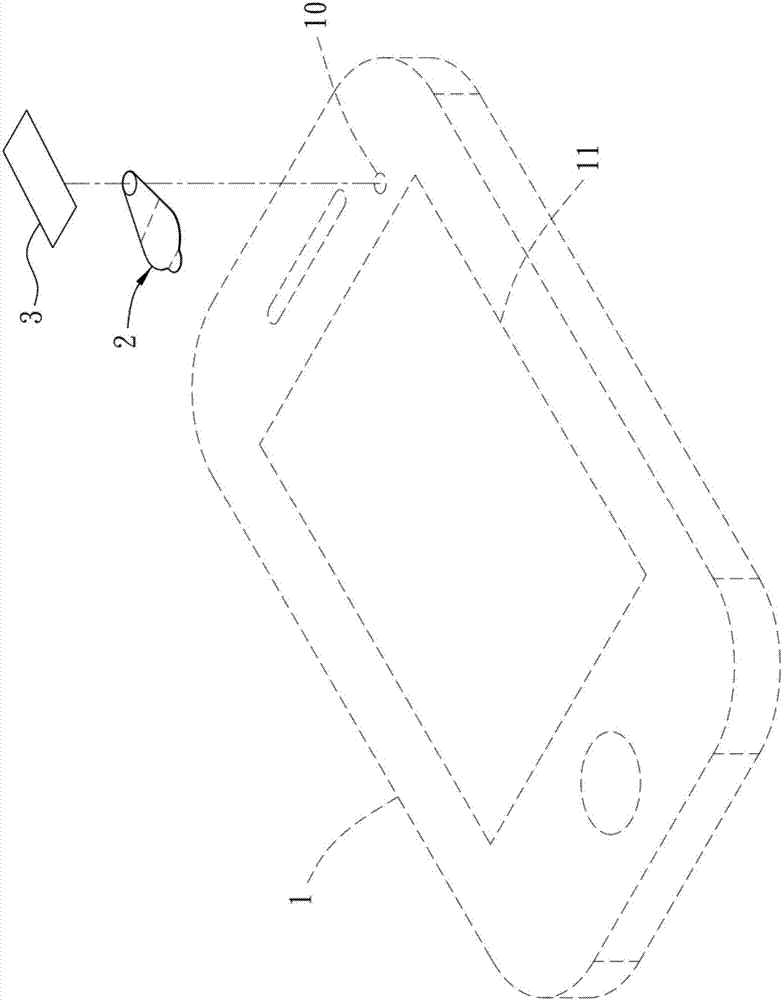

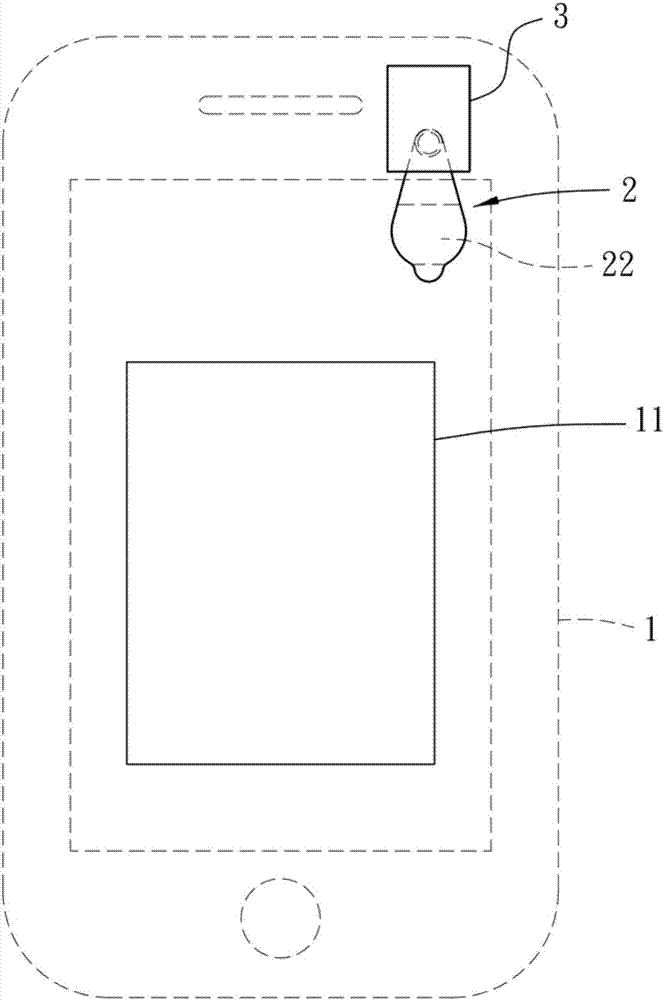

Disposable lens for identification in electronic computing devices

InactiveCN107515505ASimple structureReduce volumeCamera body detailsMaterial analysisImage signalComputer science

The invention discloses a disposable lens for identification in electronic computing devices. The disposable lens comprises a substrate, a lens and fixing glue. A user only needs to fix the disposable lens to an electronic computing device having an image capturing unit and make the image capturing unit align with an identification unit to be identified through the lens so that the identification unit amplifies an image through optical characteristics via the lens. The image captured by the image capturing unit is clearer, and the image signal is then processed by the electronic computing device. Due to the simple structure of the disposable lens, the disposable lens not only has the advantages of small size and convenient portability, but also enables the user to immediately recognize the identification unit. The disposable lens has the advantages of low material cost and is also has relative advantages on size, convenience and cost aspects.

Owner:李明叡 +1

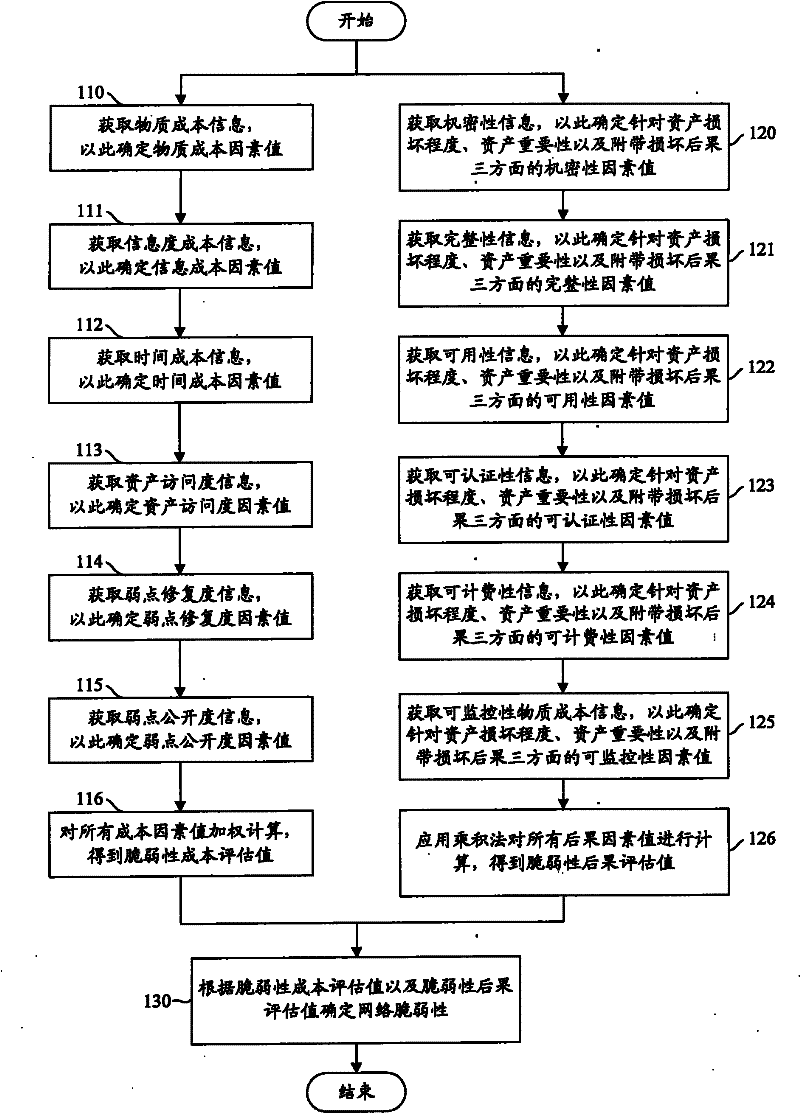

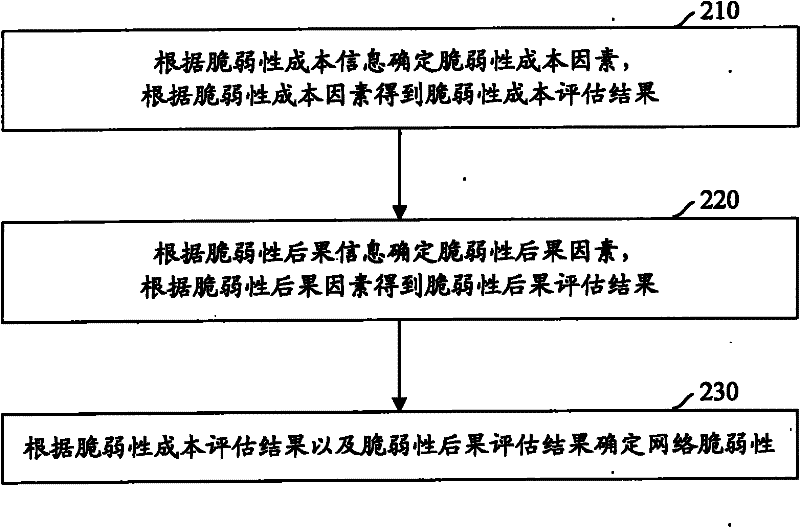

Network vulnerability evaluation method

InactiveCN101964730BImprove accuracyAvoid bad consequencesData switching networksCost evaluationSecurity Measure

The invention discloses a network vulnerability evaluation method. The method comprises the following steps of: determining vulnerability cost factors according to vulnerability cost information; obtaining a vulnerability evaluation result according to the evaluation cost factors; determining vulnerability consequence factors according to vulnerability consequence information; obtaining a vulnerability consequence evaluation result according to the vulnerability consequence factors; and determining network vulnerability according to the vulnerability cost evaluation result and the vulnerability consequence evaluation result. Therefore, the method of the invention takes the vulnerability cost factors and the vulnerability consequence factors into consideration comprehensively when evaluates the network vulnerability, and enriches and perfects the basis for network vulnerability evaluation in a targeted way, so that the accurate performance of the network vulnerability evaluation is improved obviously. Moreover, the obtained improved network vulnerability evaluation accuracy can provide important reference for network safety management, ensures that corresponding safety measures canbe implemented more targeted in a planned manner based on the reference, and avoids a serious result caused by utilizing the network vulnerability.

Owner:BEIJING UNIV OF POSTS & TELECOMM +1

Lighting device and lighting tool

InactiveCN102003666BCost containmentCost advantageElectric circuit arrangementsLighting heating/cooling arrangementsEffect lightEngineering

The invention relates to a lighting device and a lighting tool. A semiconductor light-emitting element favorable for the cost aspect is used as the light source. The lighting device (10) comprises a thermal-conductive main body (13) with a substrate support part (13e) at one end; a substrate (14) provided with the semiconductor light-emitting element (11) and arranged on the substrate support part of the main body; a conductive wire-winding pin (15) arranged on the substrate and connected with the semiconductor light-emitting element (11); a lighting device (12) housed in the main body and lighting the semiconductor light-emitting element; a conductor for power supply (16) with one end connected with the lighting device and another end winded and connected with the wire-winding pin; a light seat part (17) arranged at another end side of the main body and connected with the lighting device. The lighting tool comprises a tool main body with a socket and the lighting device mounted on the socket of the main body. The cost is effectively reduced.

Owner:TOSHIBA LIGHTING & TECH CORP +1

Transport vehicle, and transport vehicle air cleaner

Provided is a haulage vehicle having an air cleaner that is realistic from the viewpoints of fabrication steps and cost aspect. An air cleaner (24) arranged in a haulage vehicle is provided with a swirling flow generator (26), a separator (27) and an outer cylindrical casing (25). The swirling flow generator has a fixed shaft (28) and a plurality of guide blades (29) arranged and shifted from one another over a predetermined angle in a direction in which the guide blades rotate about the fixed shaft, and by the plurality of guide blades, a swirling flow of cooling air is generated. The separator has a flange (32) attached on and along an inner peripheral wall of the outer cylindrical casing (25), an inner cylindrical member (30) arranged on an outer edge of a center bore of the flange, and a collection pocket (31). Dust contained in the cooling air is taken by the swirling flow into a space between the inner cylindrical member and the outer cylindrical casing and is allowed to accumulate in the collection pocket.

Owner:NIHON KENKI CO LTD

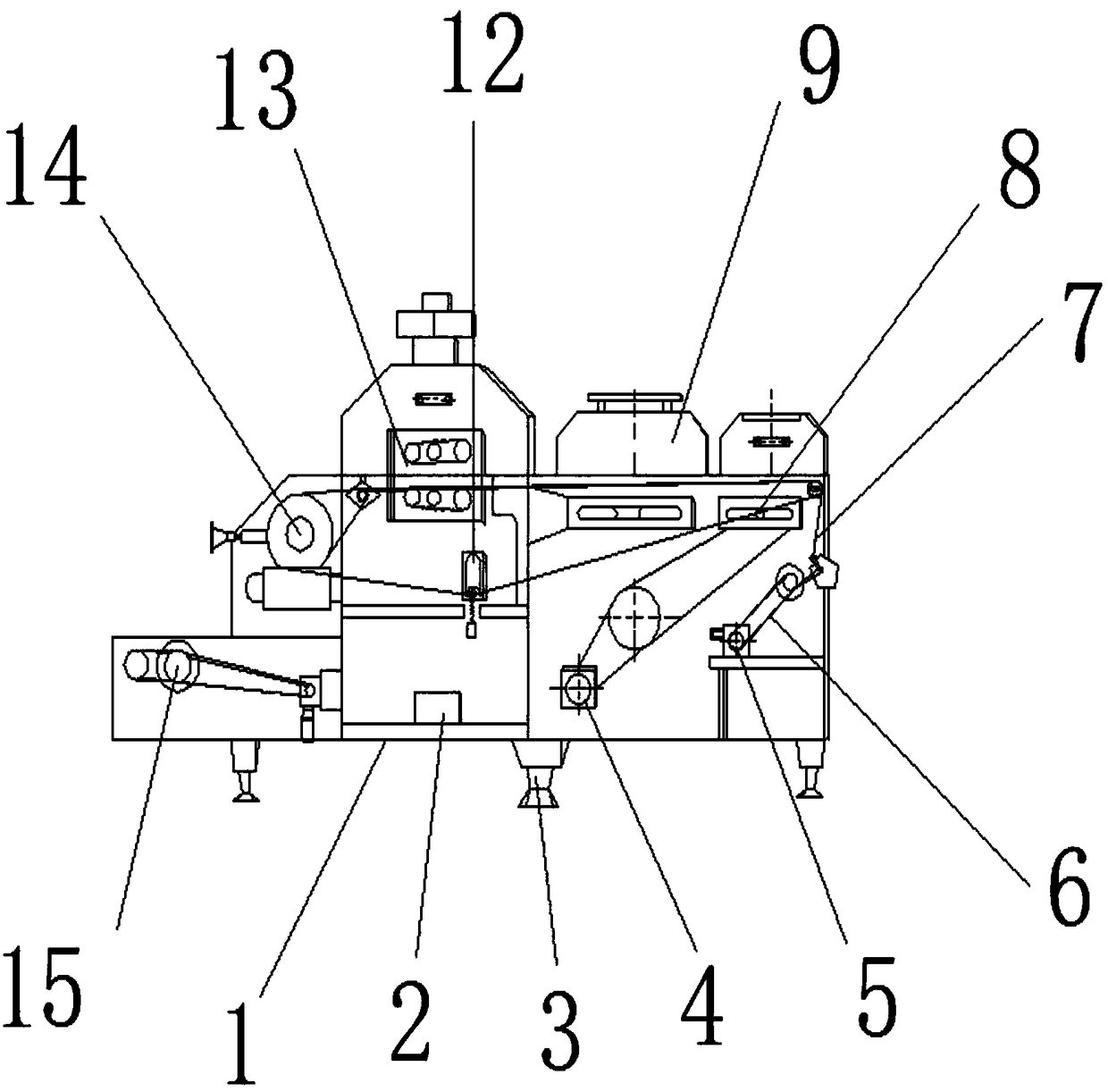

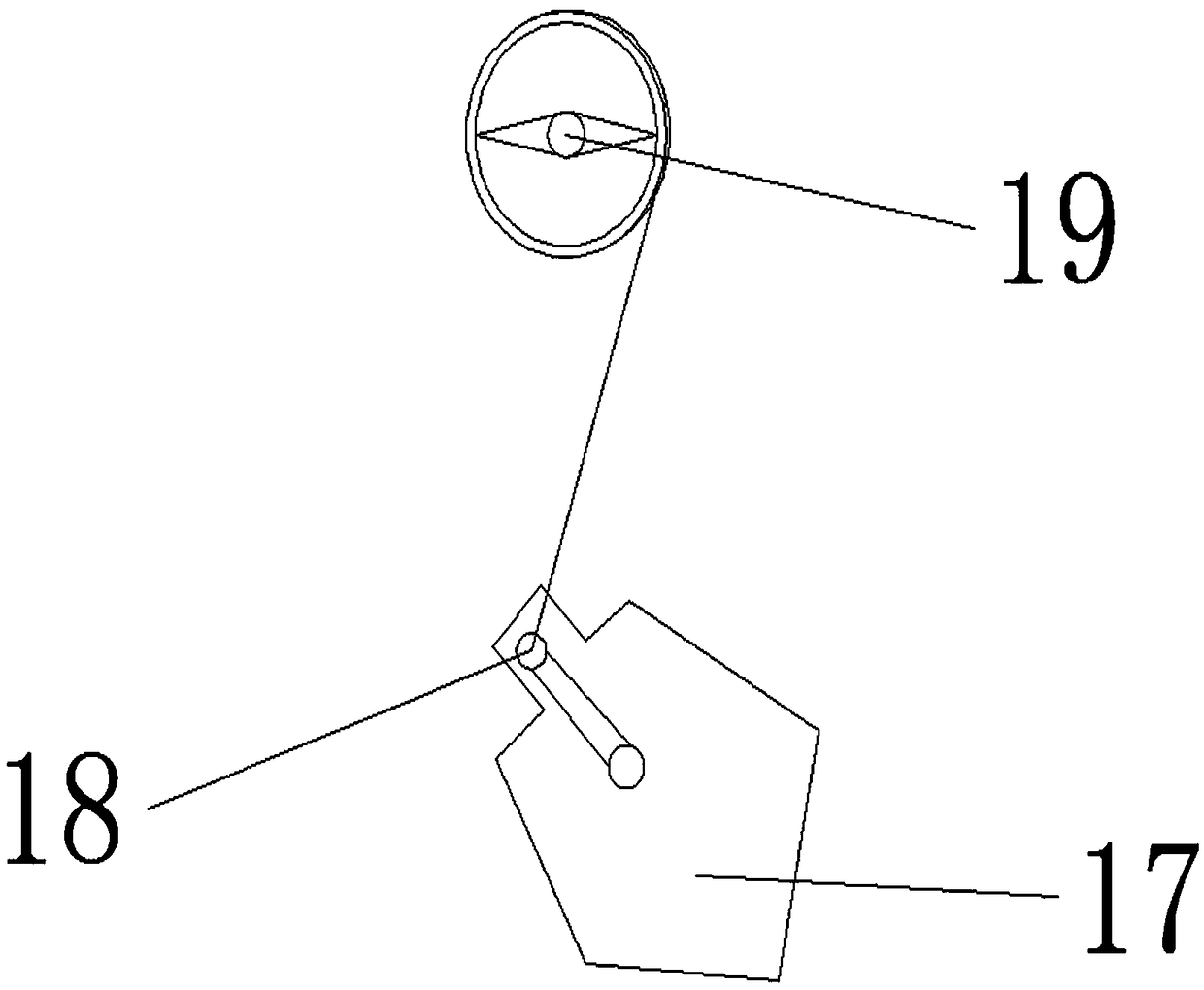

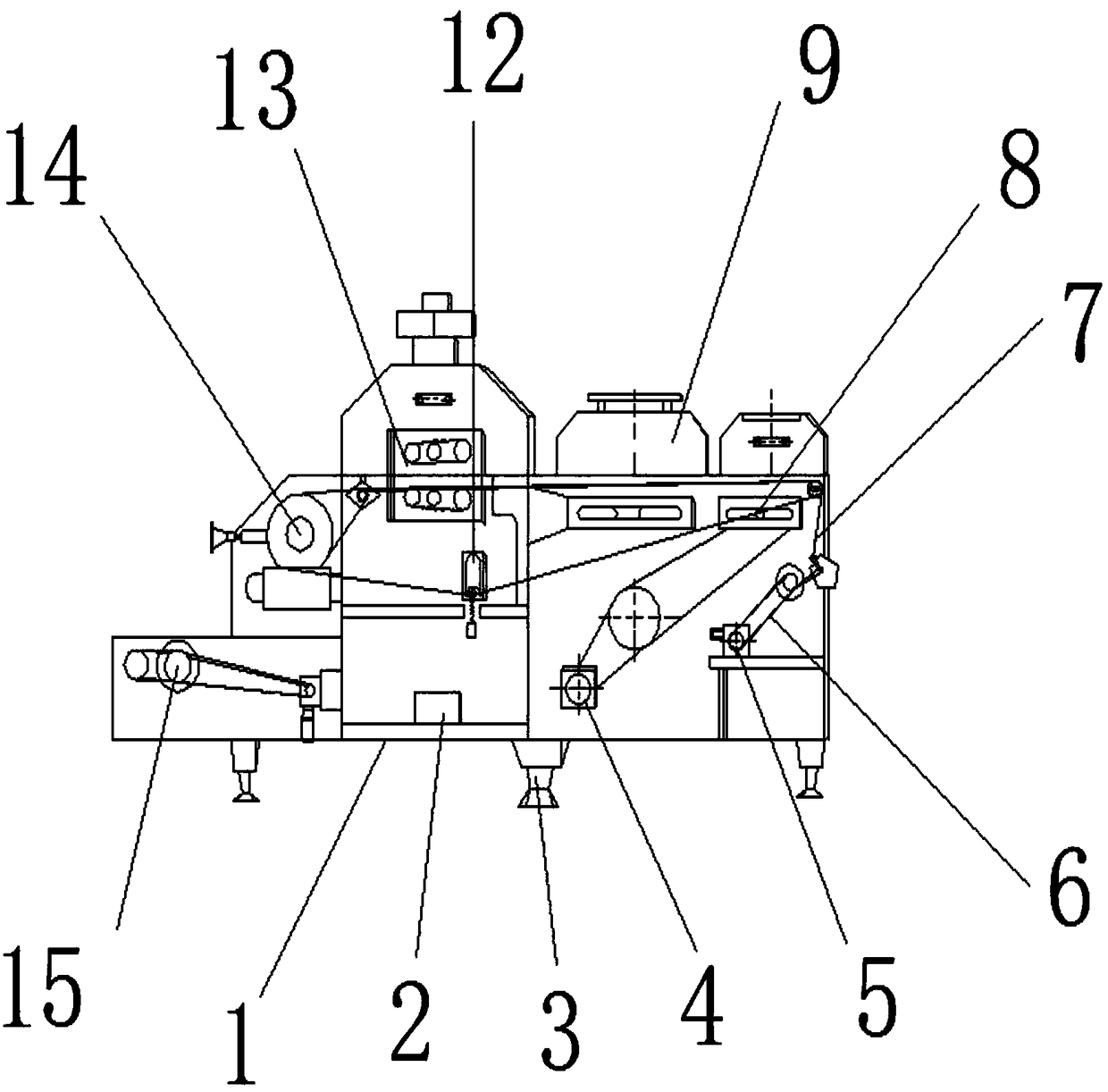

Belt regulating mechanism of fabric cutter for making socks

The invention discloses a belt regulating mechanism of a fabric cutter for making socks. The belt regulating mechanism comprises a cutter body, wherein foot stools are arranged at the positions of four feet at the bottom end of the cutter body; further, the foot stools are fixedly connected with the cutter body. Such a fabric cutter is creative in design, is simple to assemble, can be used for saving the use of fabric after being used, is used for reducing the loss of the fabric, and further, has the advantage of being attractive in design; set sock bodies are comfortably worn; the belt regulating mechanism is economical and practical in cost aspect and complete in use function; the cutting and design of the internal fabric are simple and are easy to operate; the maintenance cost is decreased; further, the better design can be professionally achieved in the prior art; the technical requirement is high; further, a device of a product system is promoted; the technical innovative space isadvanced; a steam area and a freezing area need to be combined and assembled when in use in the prior art; further, the contact usage area is greatly promoted; thus, the idealization of the use idealof the cutter is greatly improved; the connection among all components is more systematic; the time of normal work is reduced; the practicability of the device is enhanced, and the device is enabledto have a better development space on the market.

Owner:海宁市伊佳人针织有限公司

Polishing liquid applicable to AMOLED glass base plate

InactiveCN107189694AIncrease profitImprove material removal ratePolishing compositions with abrasivesLiquid wasteMaterial removal

The invention discloses a polishing solution suitable for AMOLED glass substrates, which is composed of the following raw materials in parts by weight: 4-10 parts of cerium oxide, 16-34 parts of silica sol, 7-9 parts of pH regulator, and colloidal solution 15‑22 parts, 5‑12 parts of surfactant, 6‑11 parts of oligopeptide, 35‑54 parts of deionized water. The polishing liquid prepared by the invention has a high utilization rate, reduces the production cost, and simultaneously reduces the pollution of the waste liquid of the polishing liquid to the environment; the polishing liquid of the present invention has a high material removal rate for polishing glass substrates, and there is no obvious scratch on the glass surface after polishing. The surface roughness is lower than before polishing; the polishing slurry of the present invention effectively minimizes the defects of the size controlled by the high-sensitivity defect detector on the substrate surface, and has a prolonged polishing life. Production of polished substrates with improved quality is efficient and also beneficial in terms of environmental load and cost.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

HD video processing system

ActiveCN104023202BRealize the designed functionImprove operational efficiencyClosed circuit television systemsFiltrationHigh-definition video

The invention relates to a framework of a high-definition video processing unit. The framework comprises the high-definition video processing unit, an image acquisition peripheral, a liquid crystal displayer, an ARM microprocessor, an SDRAM memory, and an AXI system bus interface connected with an image acquisition interface of the image acquisition peripheral and a liquid crystal displayer display interface as well as connected with the ARM microprocessor and the SDRAM memory . The high-definition video processing unit comprises a video processing module, a desquaring filtration module, a DMA control module, a system control module, a video adjustment control module and a high-definition display module. Different parts of the same type of chips can be selected to use according to the demands of different users, thereby meeting the demands of the majority of users well and solving the problem of functional requirements of the majority of users through reasonable configuration of a type of chips; and for the cost aspect, the design cost of a plurality of electronic products can be greatly reduced, so that the design is allowed to have better competitive edge, and the framework has wide application values.

Owner:SHANDONG UNIV

A kind of looper wheel with detachable wear-resistant layer

ActiveCN104056864BReduce the number of replacementsReduce labor intensityFlexible work arrangmentsMetal rolling arrangementsWire rodEngineering

Owner:JIANGSU YONGGANG GROUP CO LTD

Cloth cutting machine for sock making

The invention discloses a cloth cutting machine for sock making. The cloth cutting machine comprises a cutting machine body, foot stands are arranged at the four feet of the bottom of the cutting machine body, and the foot stands are fixedly connected with the cutting machine body. The cloth cutting machine is novel in design and easy to assemble; the use of cloth can be saved after the machine isused, the cloth loss is reduced, and the design is attractive; sock bodies are comfortable to wear, economical in the cost aspect and complete in use function, the internal cloth is simple in cuttingdesign and easy to operate, and the maintenance cost is reduced; besides, compared with the prior art, the machine is better in design and high in technical requirement; a product system device is improved, and the technical innovation space is advanced; according to the prior art, a steam area and a freezing area need to be combined and assembled during use; the contact use area is greatly improved, so that the use idealization of the cutting machine is greatly improved, connection between the parts is more systematic, normal work time is shortened, the device practicality is enhanced, and then the device has better development space in the market.

Owner:海宁市伊佳人针织有限公司

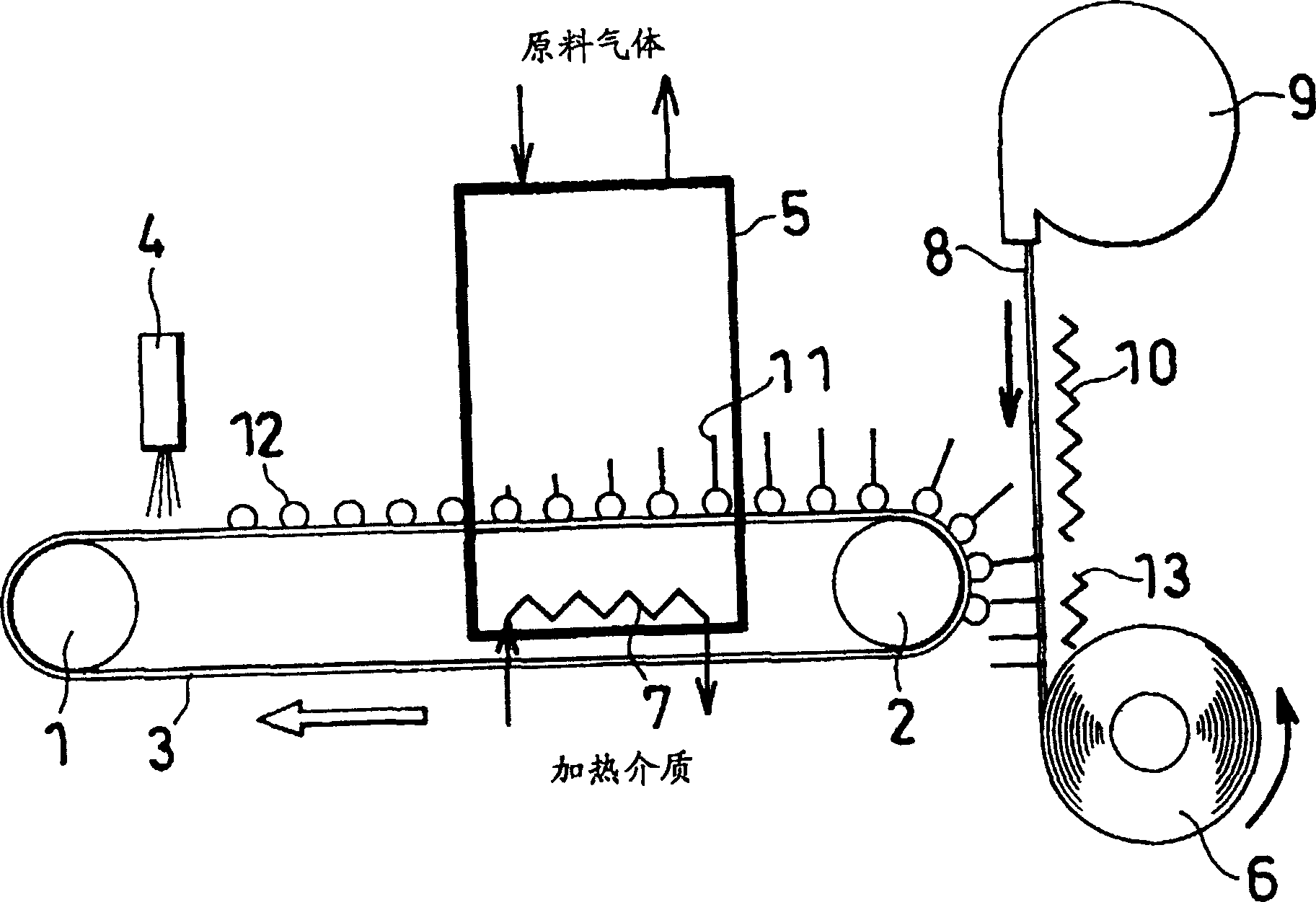

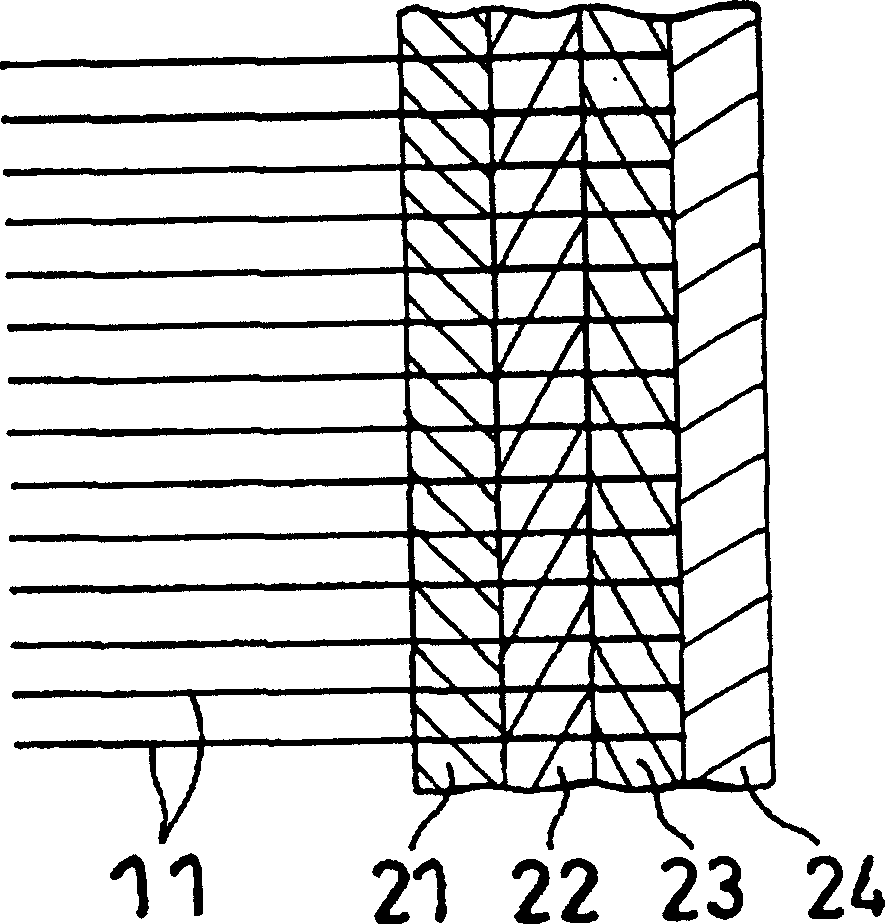

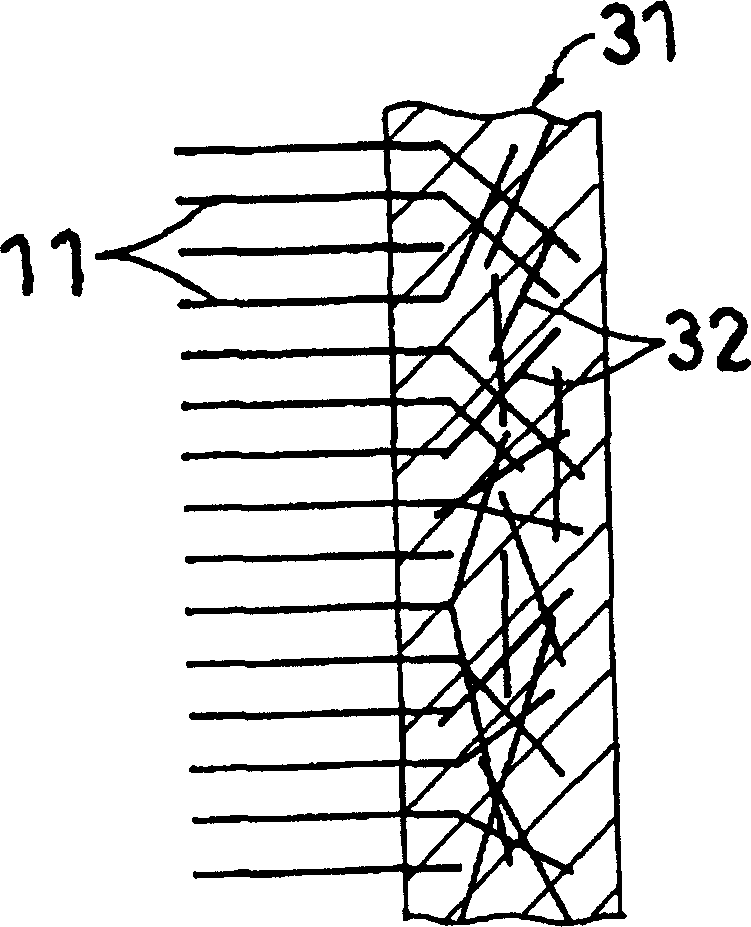

Conductive material using carbon nano-tube, and manufacturing method thereof

InactiveCN1291420CSuitable for mass productionCost advantageMaterial nanotechnologyCarbon compoundsCarbon nanotubeConductive materials

A carbon nano-tube electrode suitable for mass production and favorable in the cost aspect. Its production method is also disclosed. When the carbon nano-tube of catalyst particles on an endless belt reaches from a chemical vapor deposition zone to a transfer zone by the movement of the belt, and is gradually collapsed horizontally as the tube is turned around the outer side of a driven drum, the carbon nano-tube is pressed against a conductive film from a tip thereof. The conductive film is fed downwardly from a film feeder, and heated by a heater to the temperature not lower than the softening point and not higher than the melting point. By pressing the carbon nano-tube against the conductive film, the carbon nano-tube is transferred to a surface of the conductive film from the catalyst particles in a substantially perpendicular manner.

Owner:HITACHI ZOSEN CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com