Machining technology for low-carbon alloy steel drum brakes

A low-carbon alloy steel, processing technology, applied in the direction of brake drums, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of inner wall cracks, production equipment costs, and high production costs, reducing manufacturing costs and manufacturing costs. The effect of reducing and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

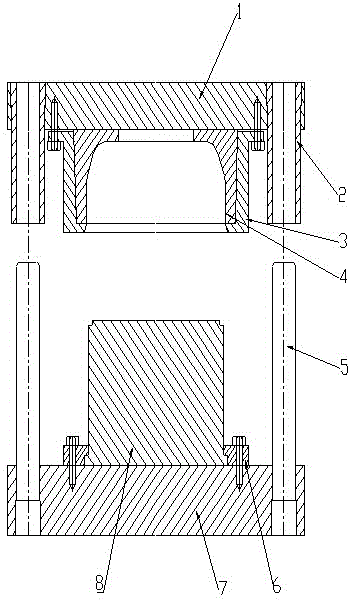

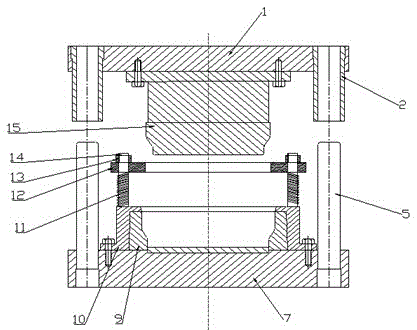

Image

Examples

Embodiment example

[0042] Below in conjunction with the accompanying drawings, the present invention will be described in detail by taking a plate with a thickness of 12 mm as an example, but the scope of protection of the present invention is not limited to the following examples of implementation;

[0043] The chemical composition of the plate of this embodiment is: by mass percentage, C: 0.30%, Si: 0.21%, Mn: 0.53%, Cr: 0.92%, Mo: 0.21%, and the rest is Fe:

[0044] The steel refining process is the same as the existing traditional steelmaking process, and is a step well known to those skilled in the art.

[0045] The method for processing the brake drum by using the above-mentioned sheet material comprises in turn:

[0046] Cutting, pre-bending, coiling, welding, bending, flattening, shaping, turning, drilling, painting and other steps, specifically:

[0047] Cutting step: Put the plate into the shearing machine, adjust the gap between the shears of the shearing machine to about 1.2 accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com