Conductive material using carbon nano-tube, and manufacturing method thereof

A technology of conductive materials and carbon nanotubes, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, hybrid/electric double layer capacitor manufacturing, etc., can solve high production costs, not suitable for mass production, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] [first step]

[0039] The Fe complex solution was sprayed onto a low-resistance N-type semiconductor silicon substrate with a thickness of 0.5 mm, and the substrate was heated to 220° C. for ion coating formation.

[0040] [Step 2]

[0041] The ion coating on the substrate is put into the CVD equipment. Acetylene as a raw material for carbon nanotubes was introduced into the CVD apparatus at a temperature of about 720° C. at a flow rate of 30 ml / min for 15 minutes. When heated in this way, the ion coating becomes fine particles, and with the obtained catalyst fine particles as nuclei, bristle-like carbon nanotubes are fabricated and gradually grown. The grown carbon nanotubes had a multilayer structure and were 12 nm thick and 50 μm long.

[0042] [third step]

[0043] The obtained bristle-like carbon nanotubes were pressed against a conductive film (CF48, product of Toray Industries Co., Ltd.) with a thickness of 0.2 mm at their outer ends, and heated to a temperat...

example 2

[0047] This example demonstrates a method for producing carbon nanotube electrodes by continuously performing the steps in Example 1.

[0048] [first step]

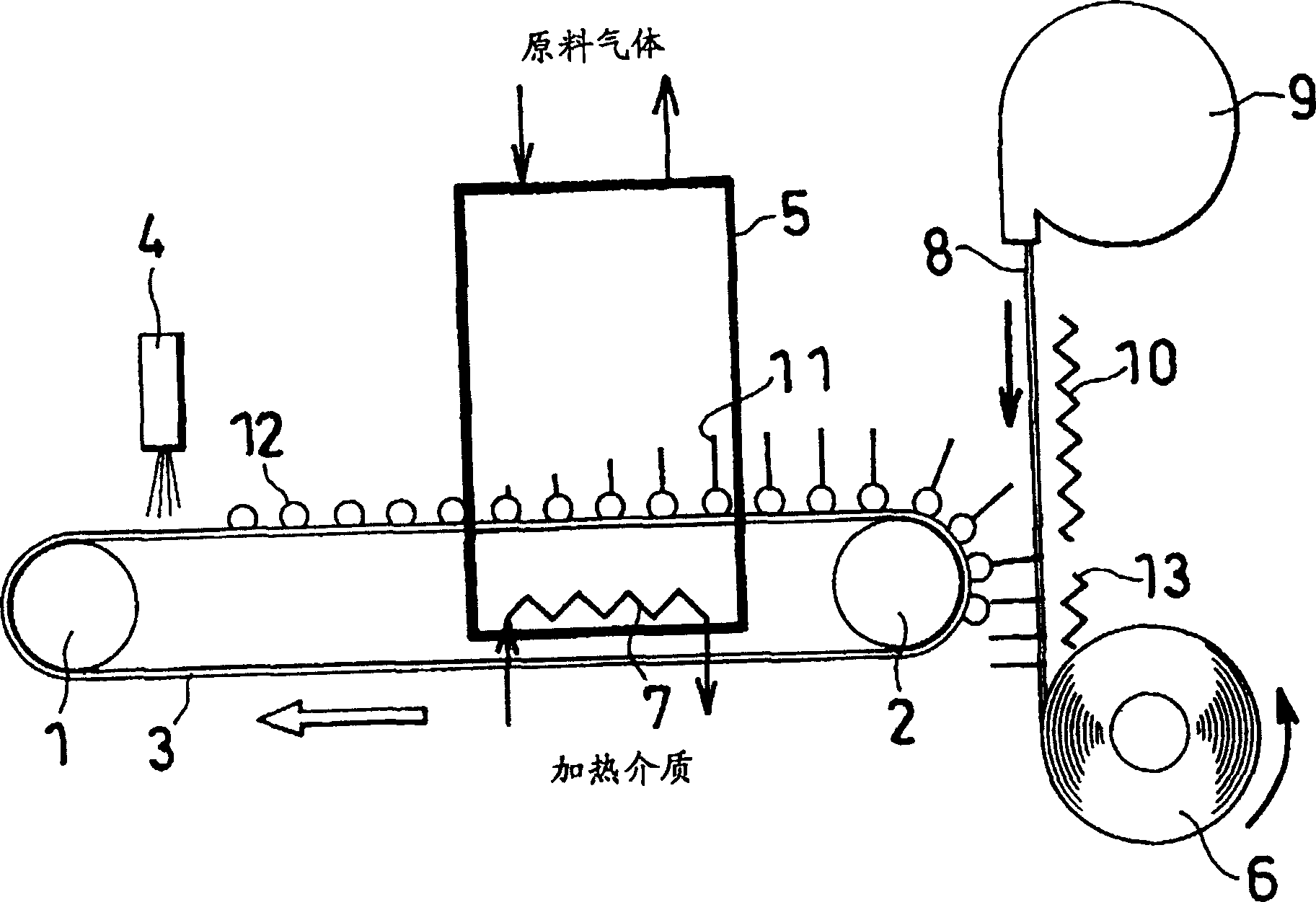

[0049] figure 1 An endless belt 3 (comprising a low-resistance N-type silicon substrate with a thickness of 0.5 mm) driven by the driving drum 1 and the driving drum 2 at a supply speed of 12 m / h is shown. The Fe complex solution is supplied from the injector 4 to the upper surface of the endless belt 3 in the catalyst deposition region of the upper side upstream portion of the belt 3, and then heated to 220° C., whereby the catalyst fine particles 12 are The stripes 3 are dispersedly formed at a pitch of 100 nm.

[0050] [Step 2]

[0051] The catalyst particles 12 on the endless belt 3 are transported to a CVD zone downstream of a catalyst deposition zone. The CVD zone comprises a furnace 5 having a length of about 2 m in the direction of belt movement and a heater 7 located inside the furnace 5 below the belt 3 . A...

example 3

[0057] [first step]

[0058] Execute the same procedure as in Example 1.

[0059] [Step 2]

[0060] Execute the same procedure as in Example 1.

[0061] [third step]

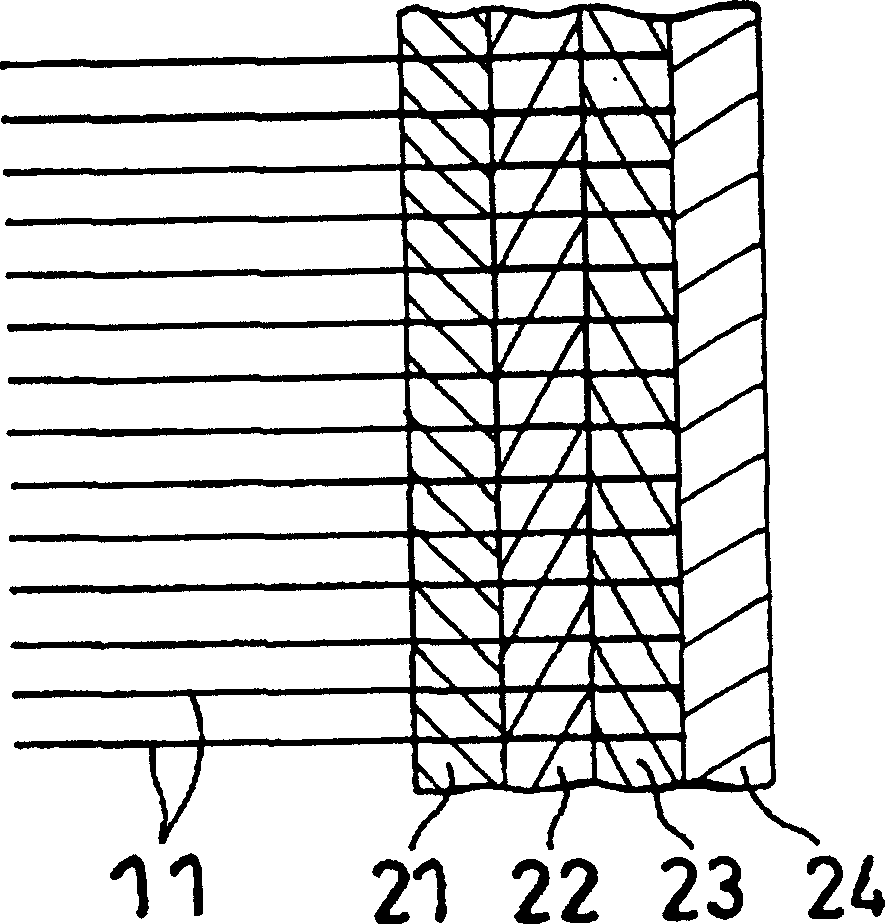

[0062] The bristle-shaped carbon nanotubes 11 formed in the second step on the 0.5mm thick low-resistance N-type semiconductor silicon substrate are pressed on their outer ends, and pressed against a multilayer conductive film heated at 95°C, thereby The carbon nanotubes are planted within the conductive film substantially perpendicular to the film surface. refer to figure 2 , arranged from the transfer side to the other side, the multilayer conductive film includes an ITO (indium tin oxide) layer 21 with a thickness of 0.01 to 0.03 μm, a base layer 22 with a thickness of 0.05 to 0.5 μm, and a thickness of 20 to 0.5 μm. A polyethylene layer 23 of 50 μm and a polyethylene terephthalate layer 24 having a thickness of 50 to 180 μm. The polyethylene layer may contain other thermally resistant films.

[0063]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com