Invisible connecting structure for crossed handrail of rail vehicle

A technology for connecting structures and rail vehicles, which is applied in the direction of connecting components, rod connections, railway car body parts, etc., which can solve the problems of increasing production cycle, purchasing cost and installation man-hours, hidden safety hazards of fasteners, and increasing vehicle costs, etc. Achieve good aesthetics, avoid potential safety hazards, and reduce procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

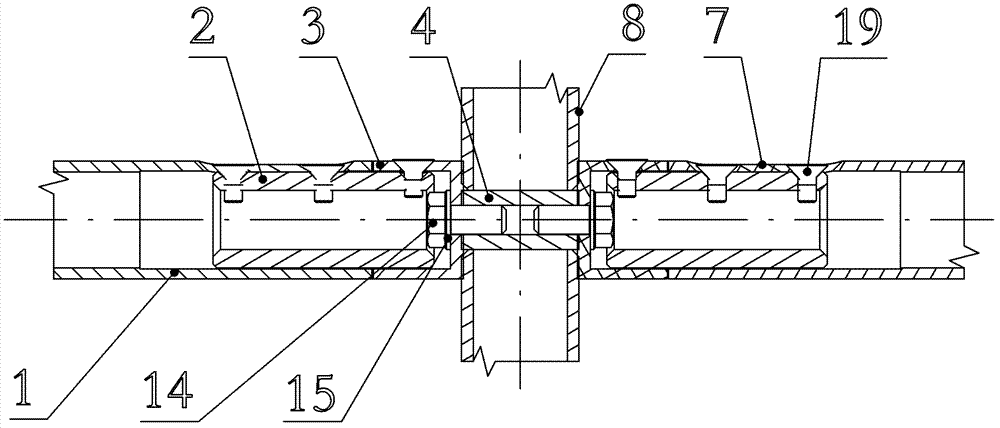

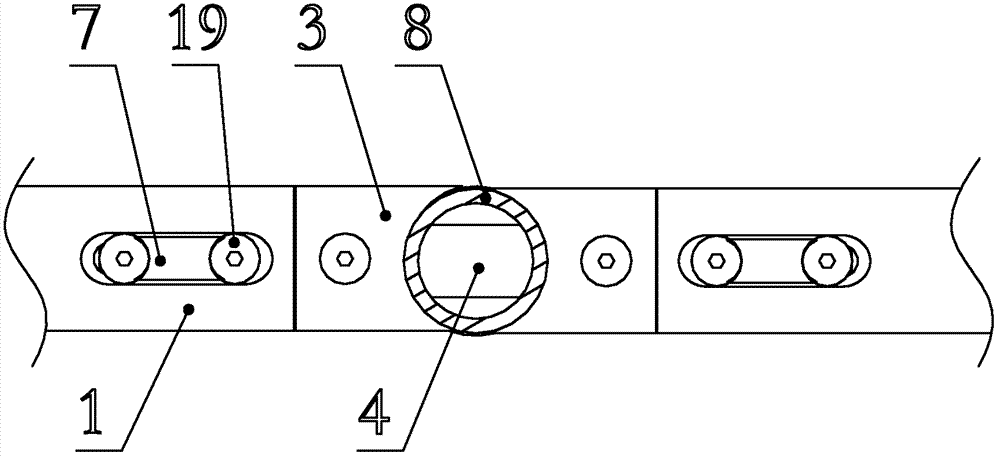

[0013] The rail vehicle cross handrail invisible connection structure of the present embodiment, as figure 1 , figure 2 As shown, it includes: vertical handrail 8, longitudinal handrail 1, which also includes connecting rod 3, connecting shaft 2, connecting rod 3 is a round tube with a closed screw hole at one end, and a threaded sleeve 4 is horizontally arranged in the vertical handrail 8, and the connecting The rod 3 is horizontally fixed on the side of the vertical armrest 8 through the hexagonal head bolt 14 and the threaded sleeve 4, the connecting rod 3 and the longitudinal armrest 1 are set on the connecting shaft 2, and the connecting rod 3 and the longitudinal armrest 1 are respectively connected to the vertical armrest 8 through the countersunk head screw 19. The connecting shaft 2 is fixed, so that the connecting rod 3 and the longitudinal armrest 1 are fixed as one.

[0014] Such as figure 1 , figure 2 As shown, a lock washer 15 is provided between the screw h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com