Automatic assembly equipment

An automatic assembly and equipment technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem that the position of the second piece of material on the first piece of material is not suitable, automation cannot be realized, and the quality of finished products is reduced. Rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

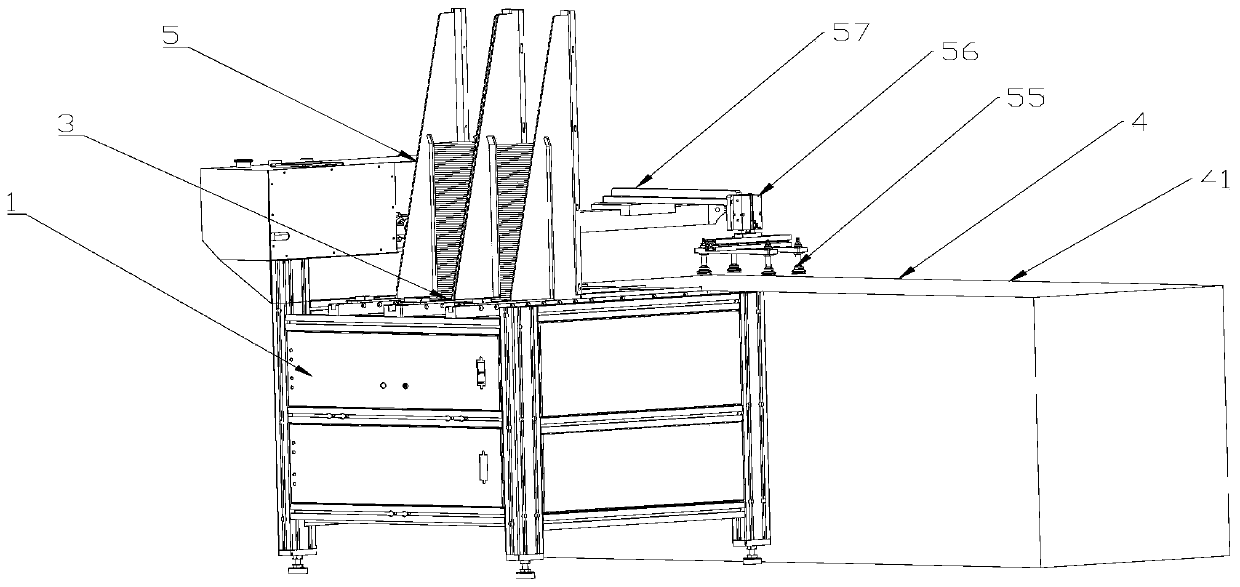

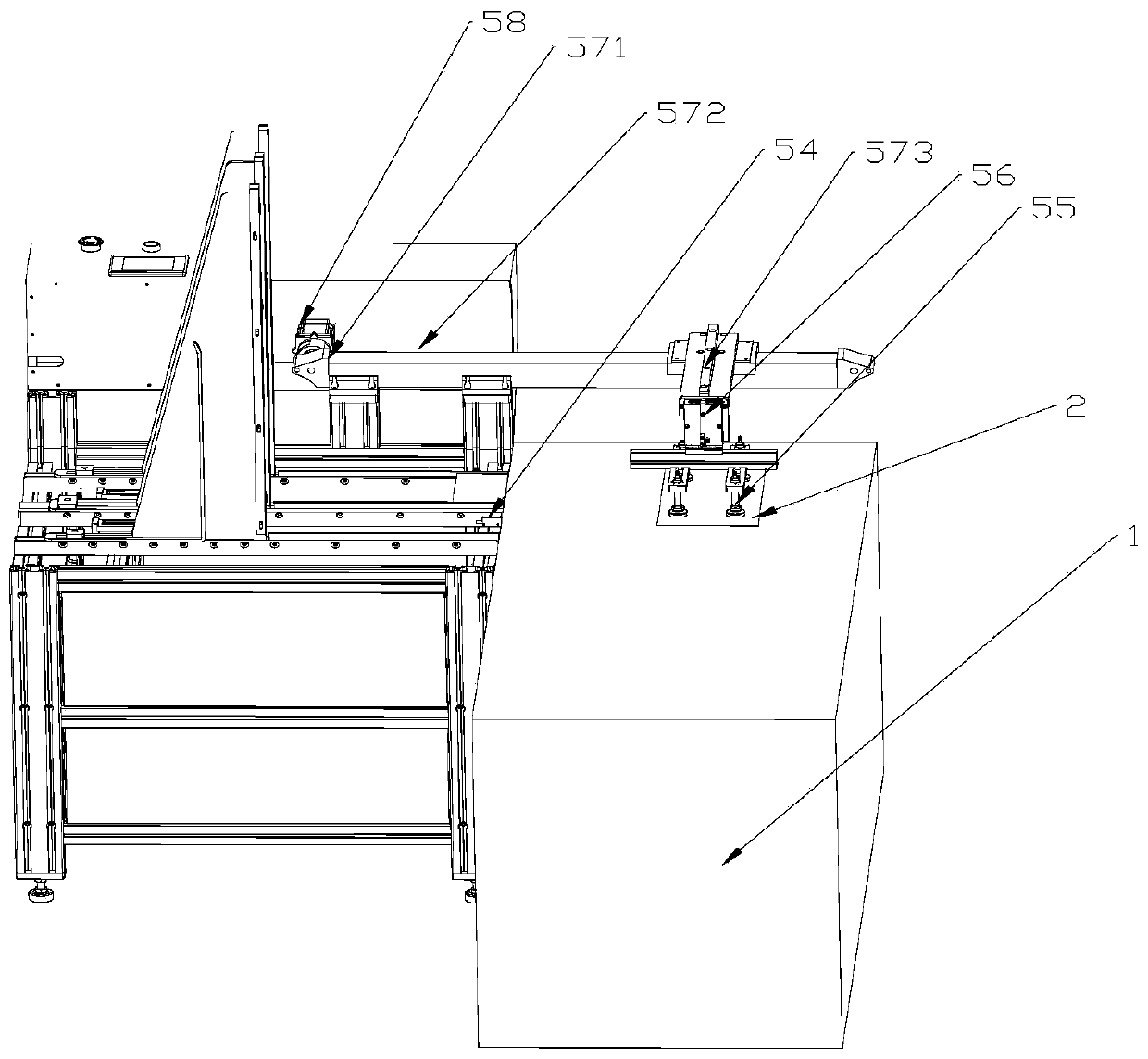

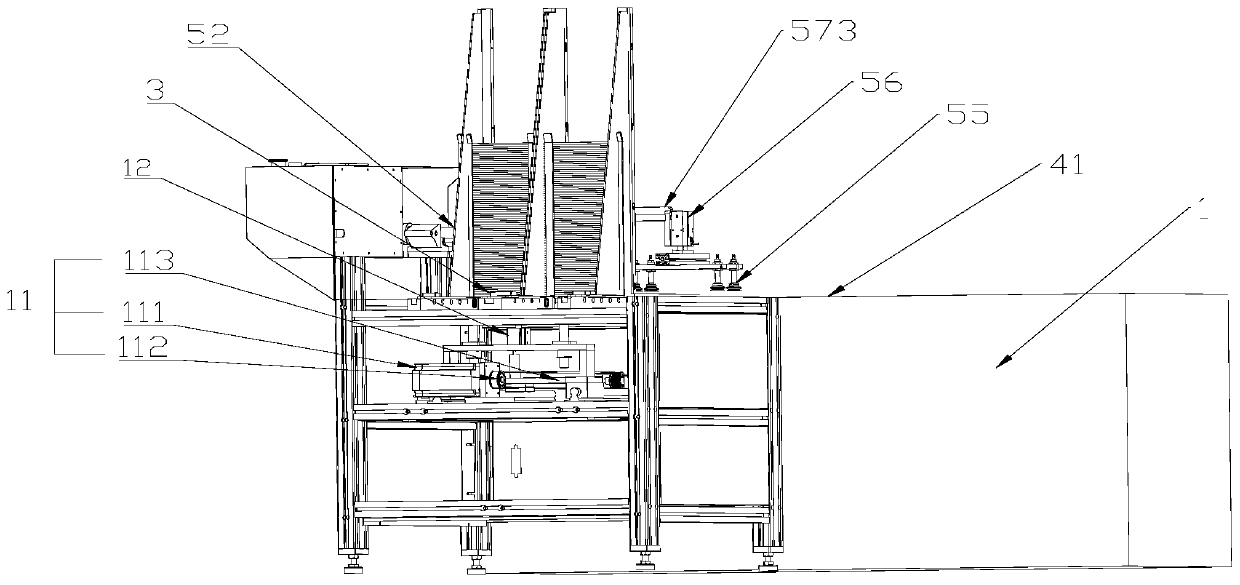

[0025] see Figure 1 to Figure 5 , an automatic assembly device, which includes: a frame 1, a first piece of material 2, a second piece of material 3, a feeding mechanism 4 and an assembly mechanism 5, and the feeding mechanism 4 and the assembly mechanism 5 are fixed on the frame 1 On the frame 1, a power drive device 11, a first lifting cylinder 12, a connecting rod 13 connected to the piston rod of the first lifting cylinder 12 are fixedly connected, and the power driving device 11, the first lifting cylinder 12 and the connecting rod 13 are arranged on The bottom of the assembly mechanism 5; the feeding mechanism 4 includes a conveyor belt for conveying the first piece of material 2; the assembly mechanism 5 includes a feeding track 51, and a stack of stacks for holding the second piece of material 3 arranged on the feeding track 51; The material frame 52, the push block 53 fixedly connected with the connecting rod 13 for conveying the second piece of material 3, the senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com