A kind of wood preservative and its application

A wood preservative, wood technology, applied in the direction of wood impregnation, wood treatment, wood impregnation, etc., can solve the problems of poor solubility of salicylic acid, difficult to fix, poor resistance to loss, etc., and achieves simple preparation process, easy implementation, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Prepare wood preservative 1#

[0028] Weigh 1.0g of salicylic acid and dissolve it in 17mL of ethanol, add 3g of composite surfactant (by mass ratio, the compounding ratio of Span80 and Tween80 is 2:3), slowly add about 80mL of water at 60°C, and then Add 2 mL of 2.5 mol / L sodium chloride solution, and stir for 10 min at a stirring speed of 500 r / min to obtain a milky white stable emulsion. After the emulsification is sufficient, slowly add a certain amount of ethyl orthosilicate (the mass ratio of salicylic acid to ethyl orthosilicate is 1:5), place it in a water bath at 60°C and stir for 3 hours to obtain a wood preservative 1#.

[0029] 2) Wood preservative treatment method

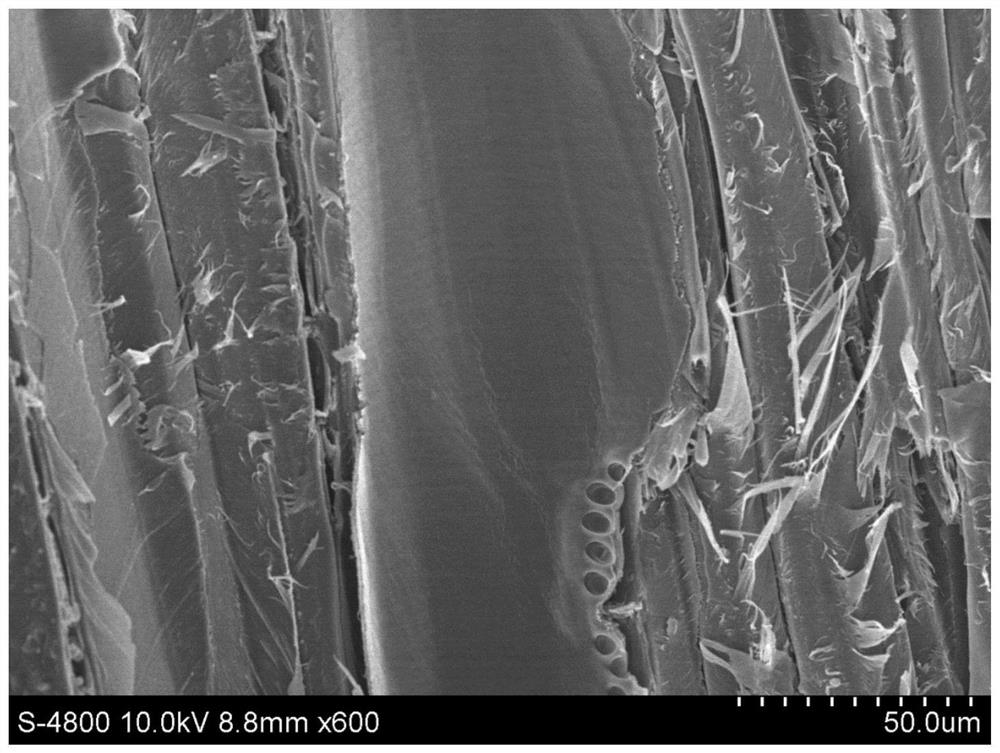

[0030] In this example, the soaking method is used to carry out anti-corrosion treatment on the test material. The test material used is Populus tomentosa (Populustomentosa). Under the condition of normal temperature and pressure, soak the Populus tomentosa specimen to be treated in wood ...

Embodiment 2

[0032] 1) Prepare wood preservative 2#

[0033] Weigh 1.0g of salicylic acid and dissolve it in 33mL of ethanol, add 3g of composite surfactant (by mass ratio, the compounding ratio of Span80 and Tween80 is 3:4), slowly add about 80mL of water at 50°C, and then Add 2mL of 2.5mol / L sodium chloride solution and stir for 10min at a stirring speed of 500r / min to obtain a milky white stable emulsion. After the emulsification is sufficient, slowly add a certain amount of ethyl orthosilicate (the mass ratio of salicylic acid to ethyl orthosilicate is 1:15), place it in a water bath at 50°C and stir for 3 hours to obtain a wood preservative 2#.

[0034] 2) Wood preservative treatment method

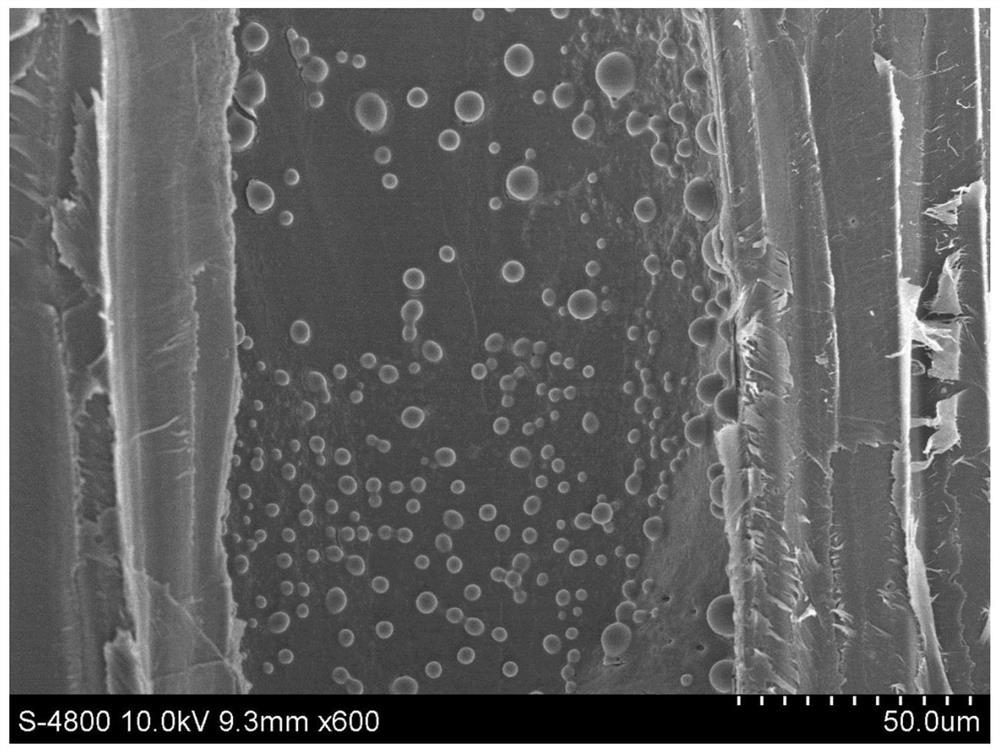

[0035] In this embodiment, the test material is subjected to anti-corrosion treatment by means of vacuum treatment. The test material used is Populus tomentosa. Populus tomentosa test piece is placed in the treatment tank, imports described wood preservative 2# in the treatment tank; The trea...

Embodiment 3

[0037] 1) Prepare wood preservative 3#

[0038] Weigh 1.0g of salicylic acid and dissolve it in 17mL of ethanol, add about 5g of composite surfactants (by mass ratio, the compounding ratio of Span80 and Tween80 is 4:5), slowly add about 80mL of water at 40°C, and then Then add 2 mL of 2.5 mol / L sodium chloride solution and stir for 10 min at a stirring speed of 500 r / min to obtain a milky white stable emulsion. After the emulsification is sufficient, slowly add a certain amount of ethyl orthosilicate (the mass ratio of salicylic acid to ethyl orthosilicate is 1:20), place it in a water bath at 40°C and stir for 3 hours to obtain a wood preservative 3#.

[0039] 2) Wood preservative treatment method

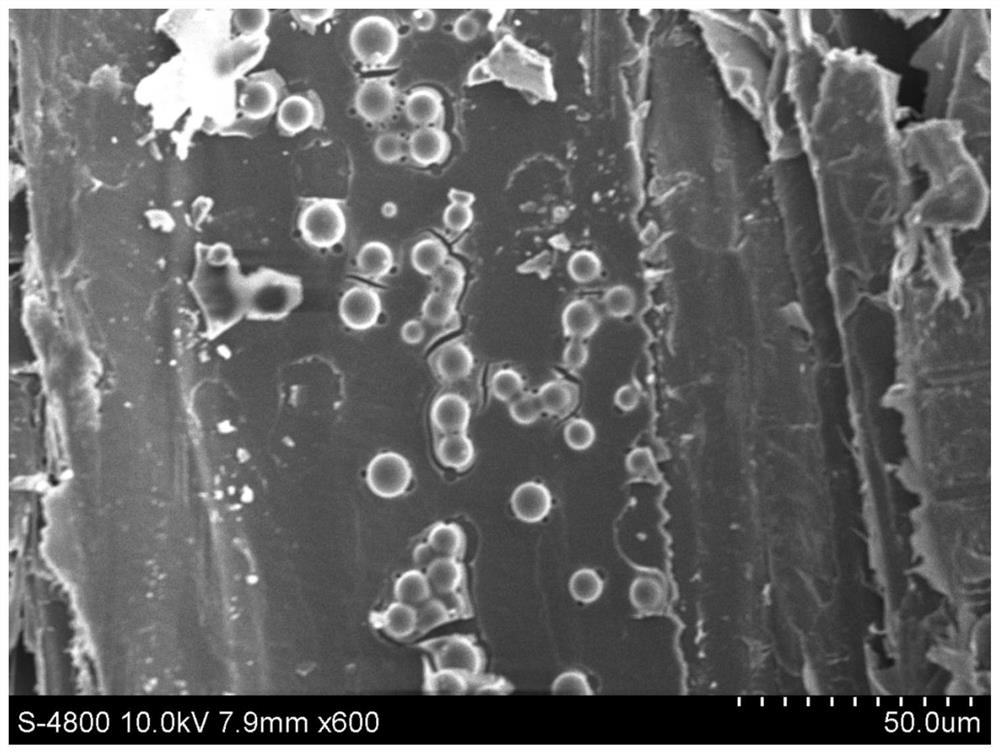

[0040] In this example, the full-cell method (vacuum pumping-pressurized impregnation treatment method) was used to carry out antiseptic treatment on the test material. The test material used is Populus tomentosa. Soak the Populus tomentosa test piece in wood preservative 3#, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com