Model mold drawing method for casting

A technology of model and draft angle, applied in casting molding equipment, mold, mold composition, etc., can solve problems such as insufficient strength of wood products, model remaining in sand mold, sand mold damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

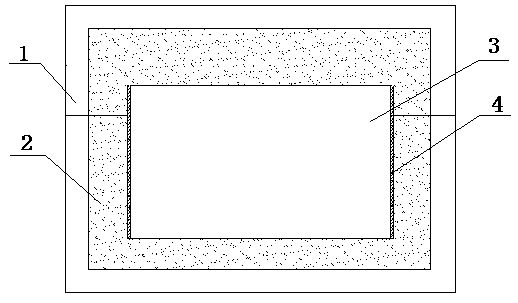

[0017] Model drafting method for casting, which is applied in the drafting process of models whose draft angle is less than 1° or requires no draft angle. A layer of paper is attached to the outer surface of the model, and the model and paper are put into the sand box together. , pull out the model after sand washing and shaping. When the model is pulled out, due to the stickiness of the sand mold, the paper is separated from the model, and the model can be pulled out smoothly due to the small friction with the paper. The paper is left on the inner wall of the sand mold and can be torn off manually.

[0018] Further, the thickness of the paper is 60-80 μm.

[0019] The so-called attachment refers to pasting the paper on the outer surface of the model in some unstable ways, such as using adhesive tape to fix several places on the paper, or pasting the paper on the model at the corner with paste, and other possible methods way and so on. This type of sticking keeps the paper o...

Embodiment 2

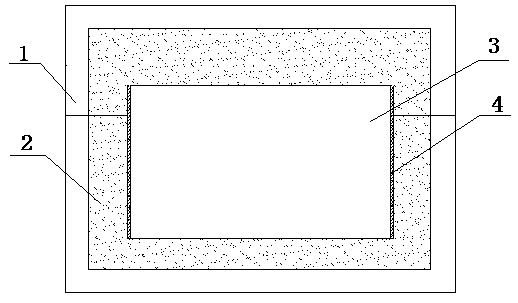

[0023] The casting model drafting method is applied to the drafting process of the model whose draft angle is less than 1° or requires no draft angle. A layer of lost foam sheet is nailed on the outer surface of the model to connect the model with the lost foam. The mold sheets are put into the sand box together, and the model is pulled out after sand washing and shaping. When the model is pulled out, due to the viscosity of the sand mold, the lost foam sheet is separated from the model, and the model is pulled out together with the nails. The nails on the model scratch the lost foam sheet, and the scratched lost foam sheet is left on the inner wall of the sand mold. , can be torn off manually.

[0024] Further, the thickness of the lost foam sheet is 2-3mm. The corresponding part of the model can be correspondingly reduced by 2-3mm or the size of the model remains the same. Due to the relatively large size of large castings, the performance of the entire casting will not be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com