Combined type packaging unit and container manufactured through same

A combined, container technology, applied in the direction of tightly closing containers with lids, containers, packaging, etc., can solve the problems of residual injection molding taste, inability to achieve injection molding, complicated processes, etc., to reduce exhaust emissions, avoid secondary pollution problems, The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

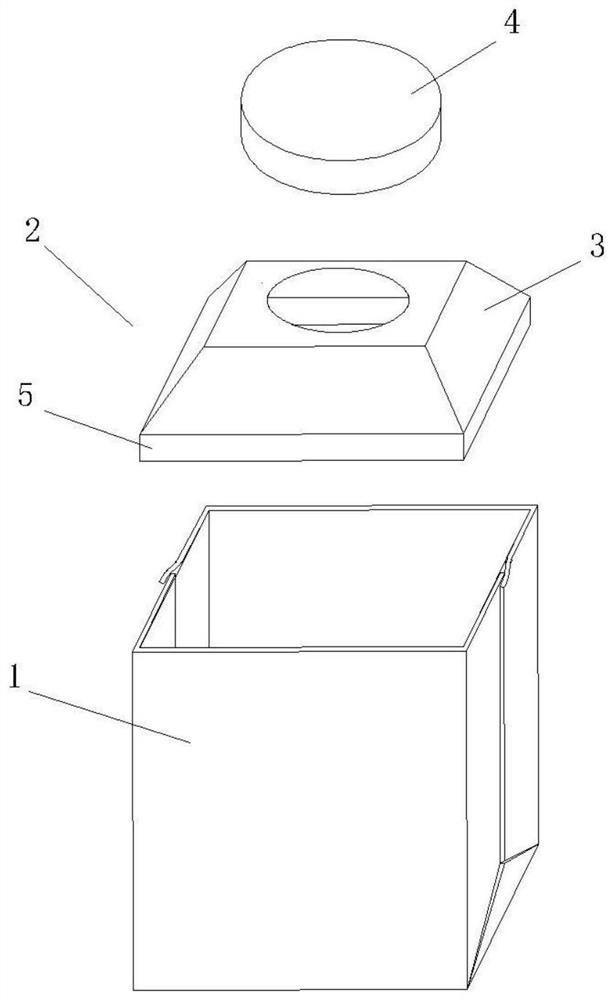

[0030] In this embodiment, the packaging unit is a combined structure, which mainly includes a unit body A1 and a unit body B2. The unit body A1 can be a conventional plate, such as a common sheet in the field or a coiled material in the field. It is cut, but the plate shape referred to in the present invention is not limited to the flat state of the unit body A1. The plate shape describes a thickness and general shape of the unit body A1, which can be a single-layer structure , It can also be a composite of multi-layer structure. There are a series of folding lines on the unit body A1, and the prototype of a container is formed after folding along the folding lines. At this time, the top of the container is open and uncovered, and the top of the container has no folding ears, so it can only be counted as a semi-finished container, such as figure 1 shown. The unit body A1 can be a single layer, but more often it is composed of multiple layers. The unit body B2 is also a comb...

Embodiment 2

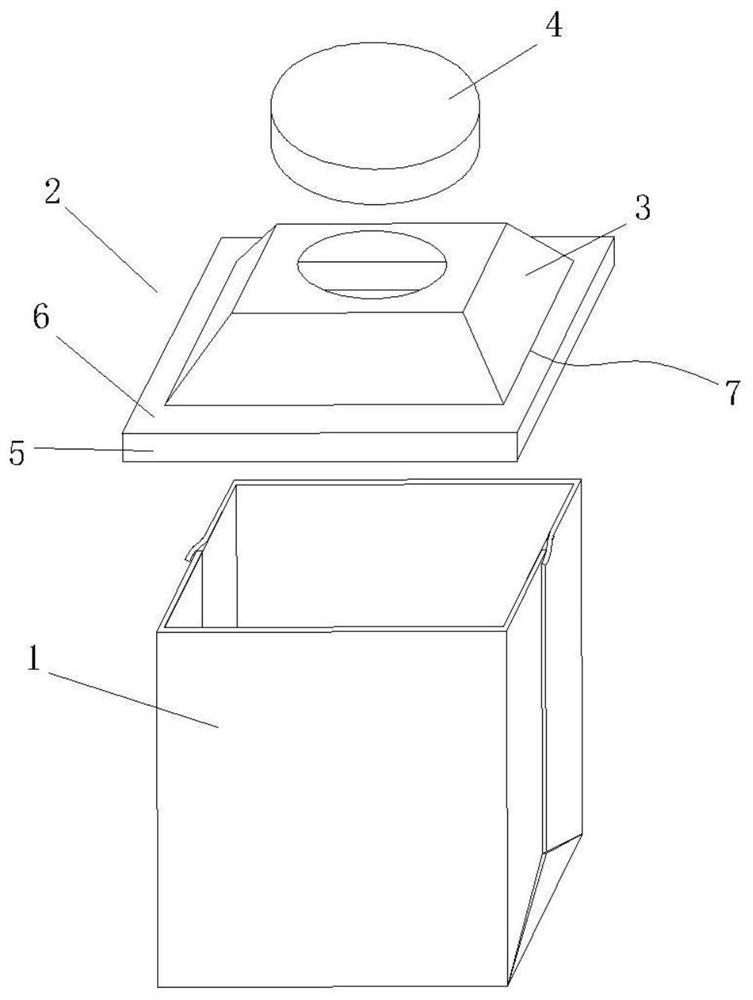

[0039] This embodiment is a first modified example of the first embodiment.

[0040] On the basis of the first embodiment, the unit body B2 not only includes the flow assembly and the contact area 5, but also includes a cover 6 and a bonding plate (not shown), and the neck 3 is fixed on the covering 6 through the bonding plate superior. Wherein the cover 6 covers the top of the container semi-finished product, and the neck 3 which plays a covering role in the first embodiment is installed on the cover 6 again, and the cover 6 should also play a sealing function except having a cover function. The cover 6 is provided with a through hole 7 for the neck 3 to communicate with. The neck 3 is connected to the cover 6 through the adhesive plate, and the adhesive plate should be fixed around the through hole 7 to ensure that the neck 3 can communicate with the through hole 7 . The contact area 5 is arranged around the edge of the cover 6 , and the function of the contact area 5 is s...

Embodiment 3

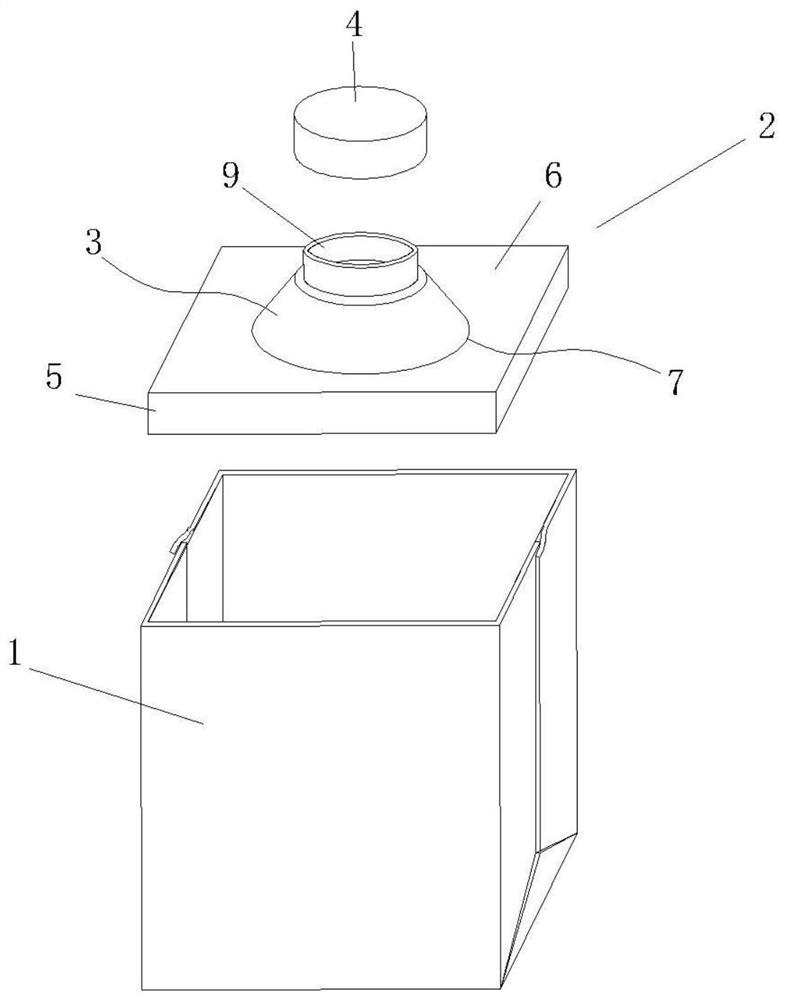

[0044] This embodiment is a preferred example of Embodiment 1 and Embodiment 2. The only difference is that the flow assembly also includes a bottle mouth 9, which is arranged on the top of the neck 3. At this time, the lid 4 is used to open and close the bottle mouth. 9. The bottle mouth 9 can adopt any existing feasible structure or shape, as the most common bottle mouth has a threaded structure outside, and the lid 4 seals it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com