Bottom structure of a container ship with concentrated arrangement of bottom girders

A bottom structure, container ship technology, applied in the direction of hull components, hull, ship construction, etc., can solve the problems of tight bottom modulus margin, heavy weight, poor rigidity, etc., to reduce welding workload, low cost, increase bottom Effects of Modulo Margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

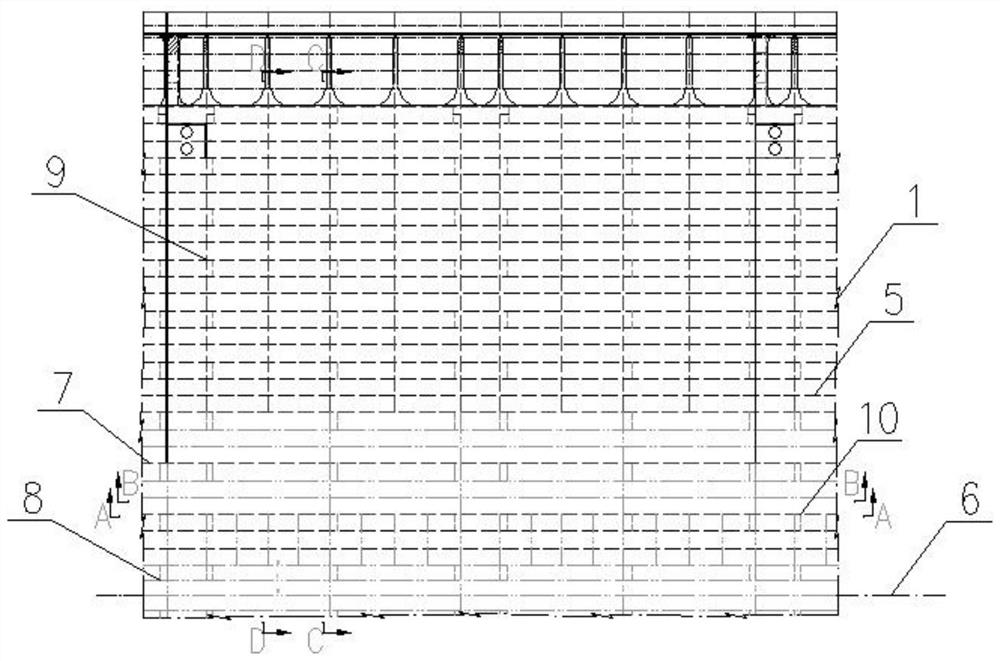

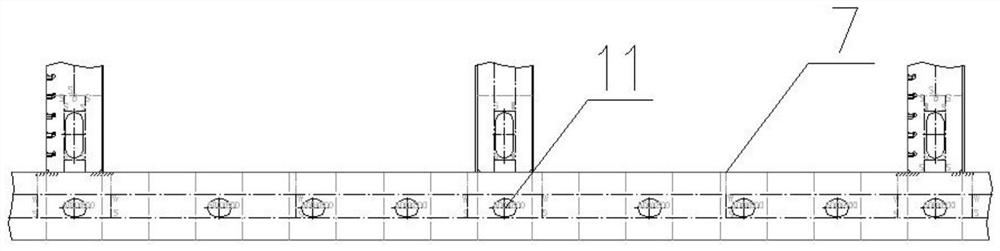

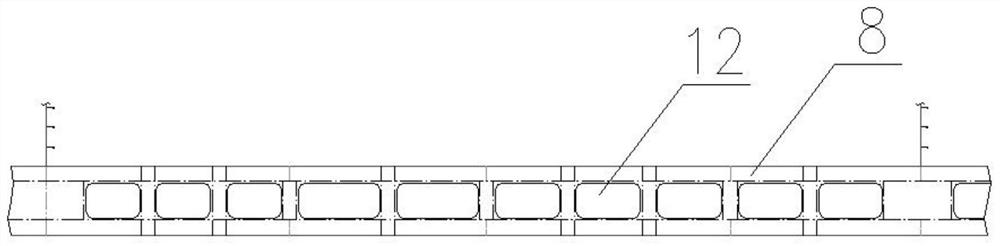

[0029] Such as figure 1 , as shown in 4 and 5, the embodiment of the present invention provides a bottom structure of a container ship with bottom girders arranged in a concentrated manner, including an outer bottom plate 1 and an inner bottom plate 2 arranged from bottom to top, and a number of container ships are arranged on the upper end of the inner bottom plate 2 3. A number of containers 3 are fixed on the inner bottom plate 2 through a number of equally spaced box feet 4 pierced through the inner bottom plate 2. Longitudinals 5 are arranged at equal intervals at several box feet 4 on the lower end surface of the inner bottom plate 2. The outer bottom plate 1 There are several longitudinals 5 corresponding to the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com