Chain traction device for chain conveyor

A chain conveyor and traction device technology, applied in the direction of conveyor, transportation and packaging, can solve problems such as unfavorable use of conveyor, troublesome removal of drive shaft, affecting the life of belt and drive shaft, etc., to improve maintenance efficiency, The effect of avoiding slippage and deviation and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

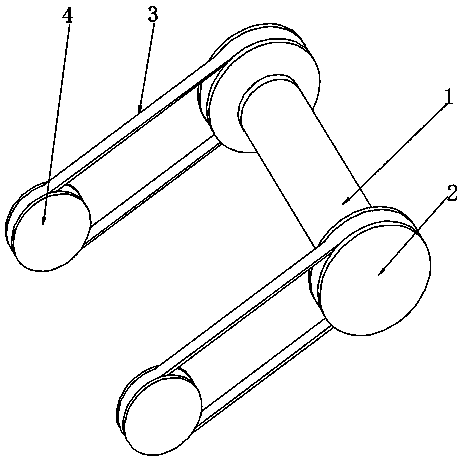

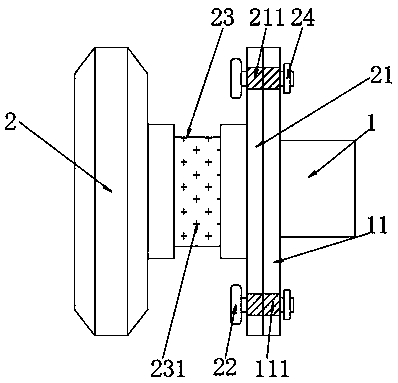

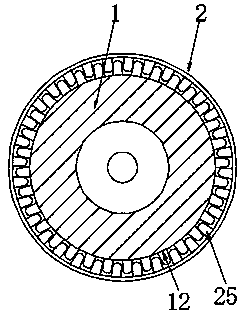

[0024] See Figure 1-4 The present invention provides the following technical solutions: a chain traction device of a chain conveyor, comprising a transmission shaft 1, a sleeve 2, a transmission belt 3 and a transmission wheel 4. The transmission shaft 1 is provided with a protective plate 11 and a gear ring A12 to protect The plate 11 is fixed on the outer wall of the transmission shaft 1, the gear ring A12 is fixed on the outer wall of the transmission shaft 1, the sleeve 2 is provided with a fixing plate 21, bolts 22, nuts 24 and a gear ring B25, and the fixing plate 21 is fixed on the sleeve 2 On one side, the bolt 22 penetrates the fixing plate 21 and is fixed on the protective plate 11, and the nut 24 is fixed on the bolt 22, the gear ring B25 is fixed on the inner wall of the sleeve 2, and one end of the transmission belt 3 is driven on the sleeve 2, and The other end of the driving belt 3 is in driving connection with the driving wheel 4, and the sleeve 2 is in driving...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap