Precipitation hardening steel plate with small material deviation in all directions and manufacturing method thereof

A technology for precipitation hardening and steel plates, which is applied in the field of precipitation hardening steel plates and its manufacturing, which can solve the problems of poor processability, uneven distribution, poor material uniformity, etc., and achieve the effect of less material deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

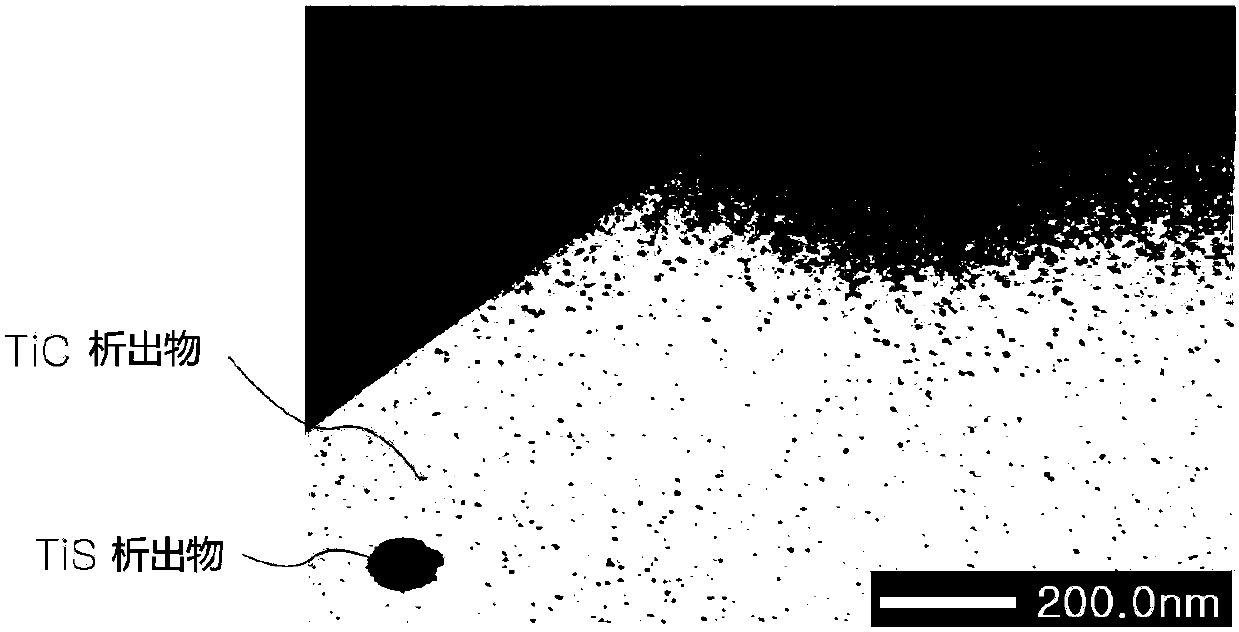

[0020] Next, a precipitation hardened steel sheet with less material variation in each direction according to one aspect of the present invention will be described in detail.

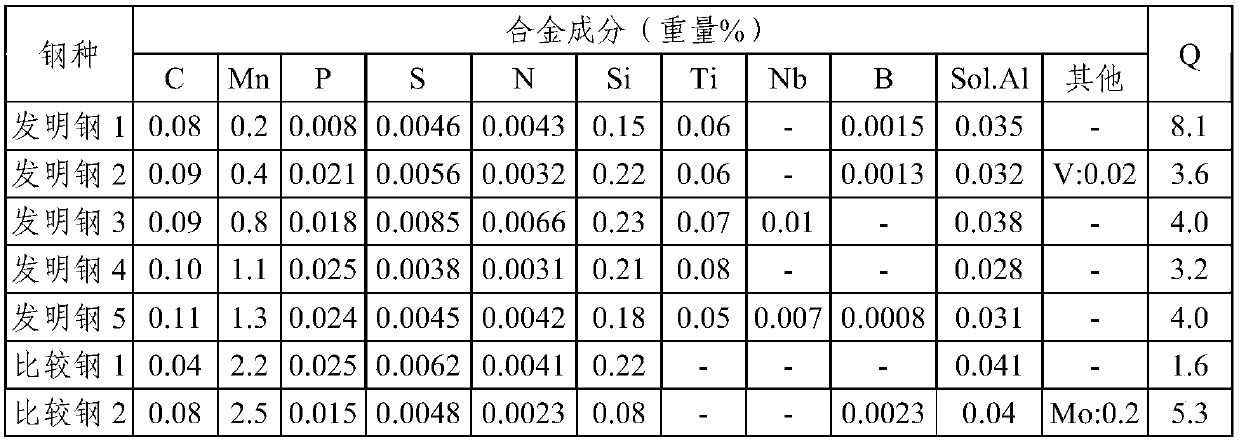

[0021] First, the alloy components and preferred content ranges of the precipitation-hardened steel sheet will be described in detail. Unless otherwise specified, the content of each component described later is based on weight.

[0022] C: 0.06 to 0.15%

[0023] Carbon is a precipitate-forming element and contributes to improving the strength of steel. When the content of carbon is too low, it is difficult to ensure an appropriate level of pearlite (pearlite) required for grain boundary strengthening, so that there is a possibility that the hole expandability will be deteriorated, and sufficient fine Ti-based precipitates cannot be obtained, so that Possibility of reduction in strength and yield ratio. On the other hand, when the content of carbon is too high, inclusion segregation bands are formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com