Thick, high tensile-strength hot-rolled steel sheets with excellent low temperature toughness and manufacturing method therefor

A technology of hot-rolled steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, metal rolling, heat treatment process control, etc., and can solve problems such as inability to ensure cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0106] A slab consisting of 0.037%C-0.20%Si-1.59%Mn-0.016%P-0.0023%S-0.041%Al-0.061%Nb-0.013%Ti-the balance being Fe in mass% was used as a steel material. In addition, (Ti+Nb / 2) / C was 1.18.

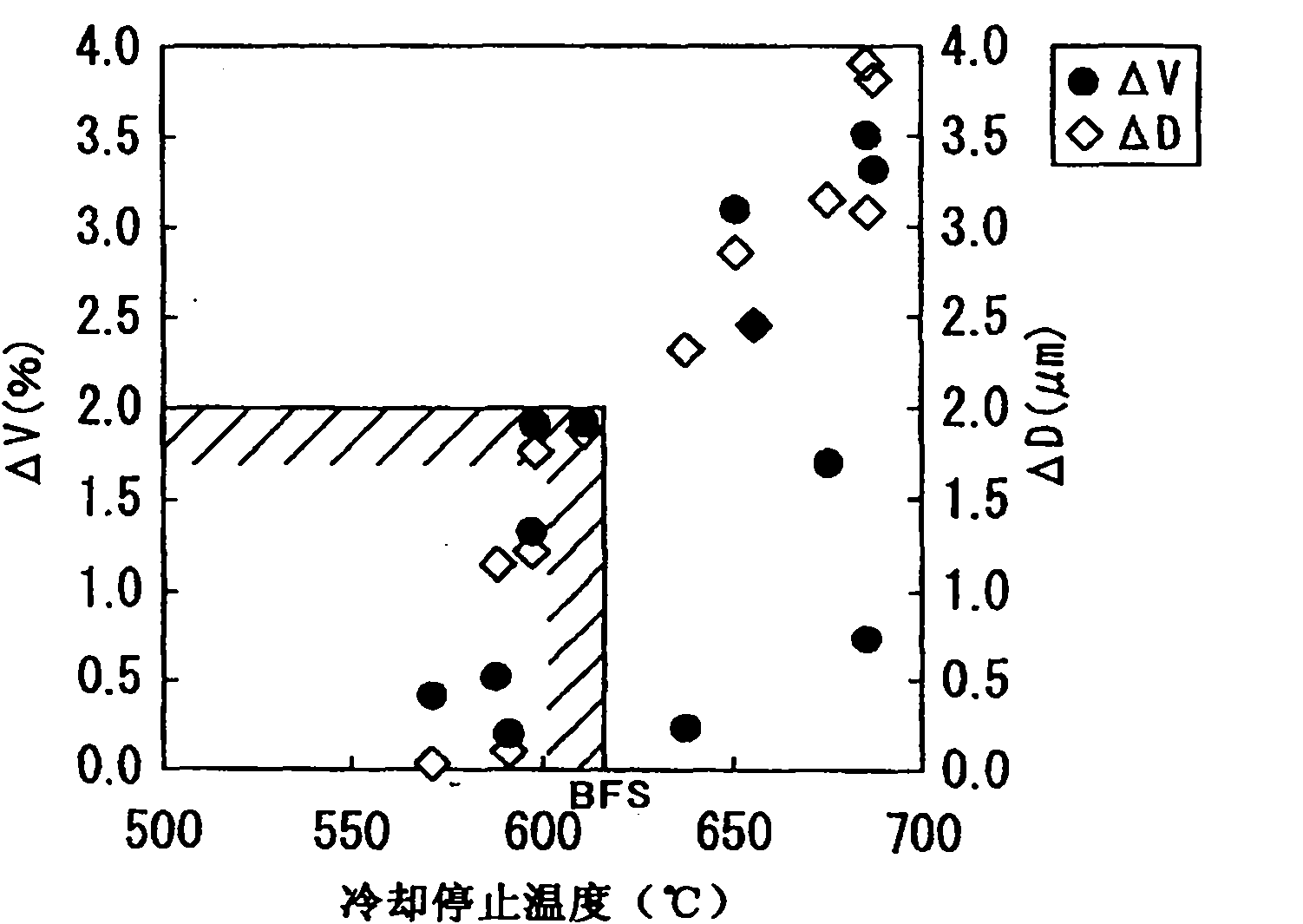

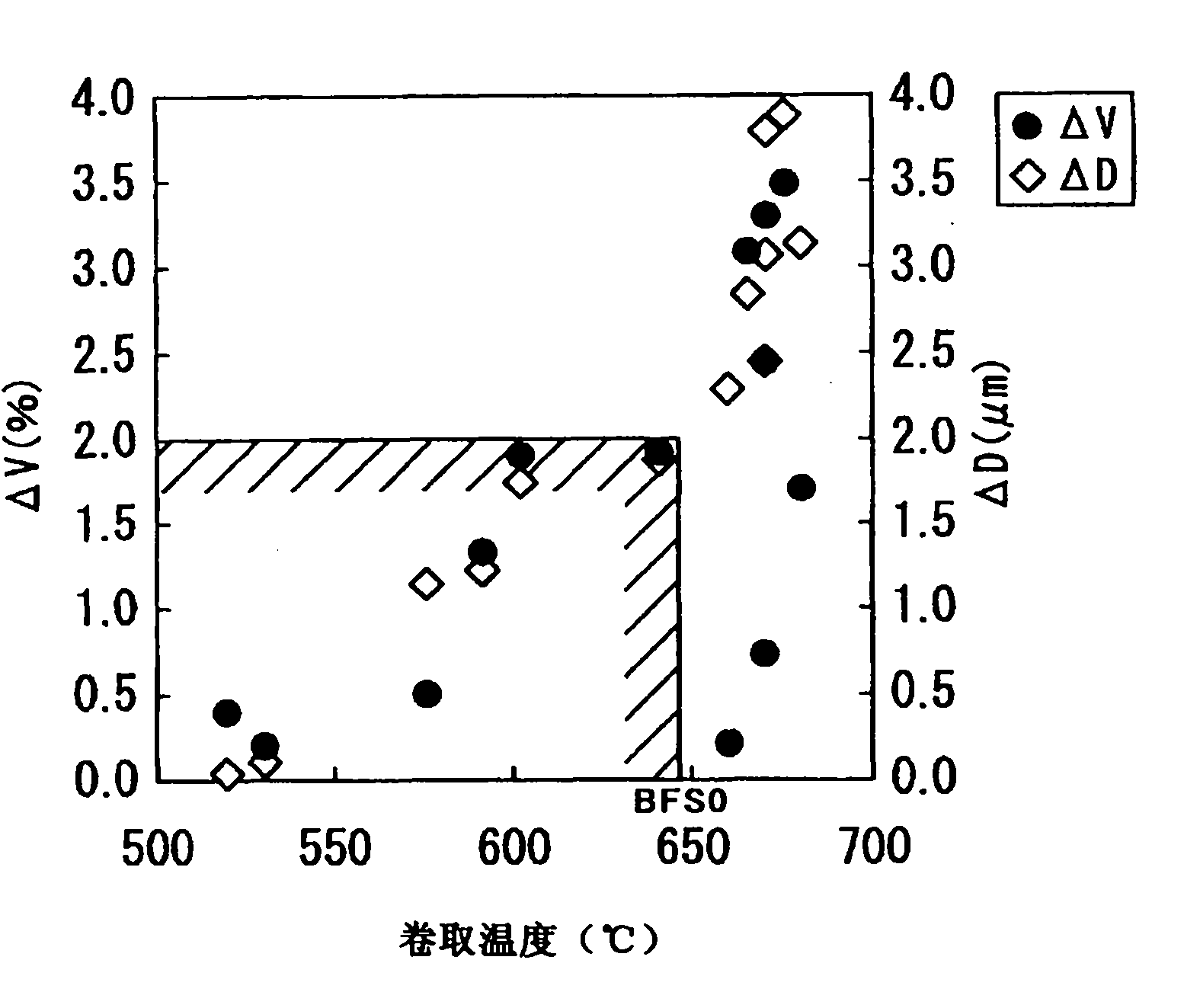

[0107] Heating the raw material of steel with the above composition to 1230°C, performing hot rolling at a finish rolling start temperature of 980°C and a finish rolling finish temperature of 800°C to produce a hot-rolled sheet with a plate thickness of 14.5mm, after the hot rolling is completed, implement Cool at a cooling rate of 18°C / sec in the temperature range where the temperature at the central position of the plate thickness is higher than 750°C until reaching various cooling stop temperatures for accelerated cooling, and then, at various coiling temperatures (central position of the plate thickness) temperature) to make a hot-rolled steel sheet (steel strip).

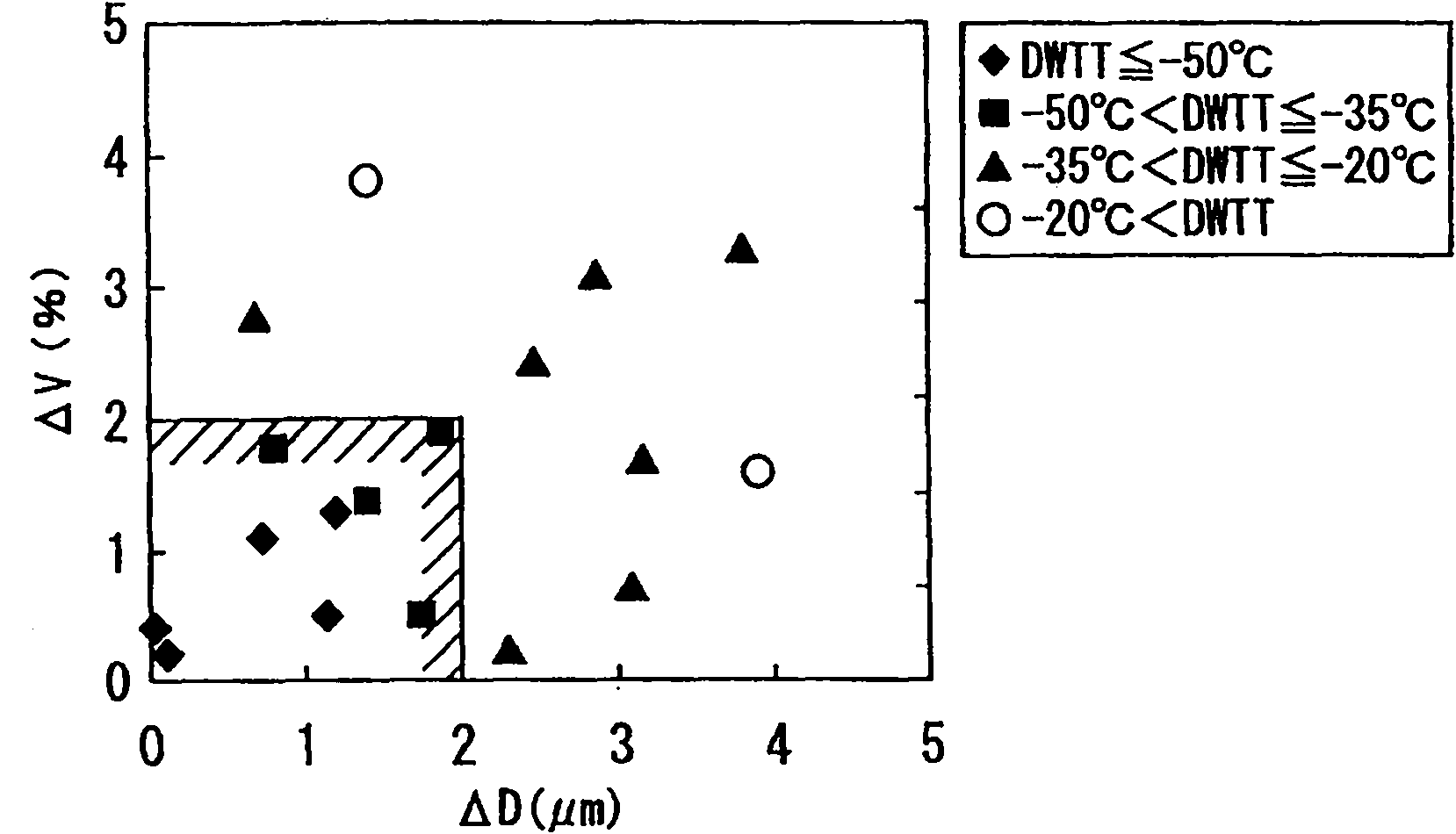

[0108] Test pieces were cut out from the obtained hot-rolled steel sheets, and the microstructure and DWTT characteris...

experiment example 3

[0129] Using mass % 0.04~0.06%C-0.2~0.7%Si-0.93~1.84%Mn-0.030~0.048%Al-0.045~0.15%Nb-0.009~0.03%Ti-0~0.25%Ni-0~0.25 %Cu-0-0.059%V-The balance is composed of Fe and unavoidable impurities, and a steel slab having a carbon equivalent Ceq of 0.234-0.496 is used as a steel raw material. In addition, the carbon equivalent Ceq was calculated using the following formula.

[0130] Ceq(%)=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15...(4)

[0131] (Here, C, Mn, Cr, Mo, V, Cu, and Ni are the content (mass %) of each element)

[0132] Heating the raw material of steel with the above composition to 1200°C, performing hot rolling at a finish rolling start temperature of 1010°C and a finish rolling finish temperature of 810°C to produce a hot-rolled sheet with a plate thickness of 25.4mm, after the hot rolling is completed, implement Perform various cooling under the following conditions until the accelerated cooling reaches the cooling stop temperature of 470°C to 490°C with the thermometer at the cent...

experiment example 4

[0138] Using mass % 0.04~0.06%C-0.20~0.70%Si-0.93~1.84%Mn-0.030~0.048%Al-0.045~0.15%Nb-0.009~0.03%Ti-0~0.25%Ni-0~0.25 %Cu-0-0.06%V-The balance is composed of Fe and unavoidable impurities, and a steel slab with a carbon equivalent Ceq of 0.234-0.496 is used as a steel raw material. In addition, the carbon equivalent Ceq was calculated using the following formula.

[0139] Ceq(%)=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15...(4)

[0140] (Here, C, Mn, Cr, Mo, V, Cu, and Ni are the content (mass %) of each element)

[0141] Heating the raw material of the above-mentioned composition to 1210°C, performing hot rolling at a finish rolling start temperature of 1000°C and a finish rolling finish temperature of 800°C to produce a hot-rolled sheet with a plate thickness of 25.4mm, after the hot rolling is completed, implement Cooling is carried out under the following conditions until the cooling stop temperature reaches a cooling stop temperature of 200°C to 500°C with a thermometer at the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com