A method for calibrating the probe length of a revo measuring head

A calibration method and probe technology, which is applied in the field of REVO probe probe length calibration, can solve problems such as the impact of calibration accuracy, achieve high-precision calibration, and eliminate calibration errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

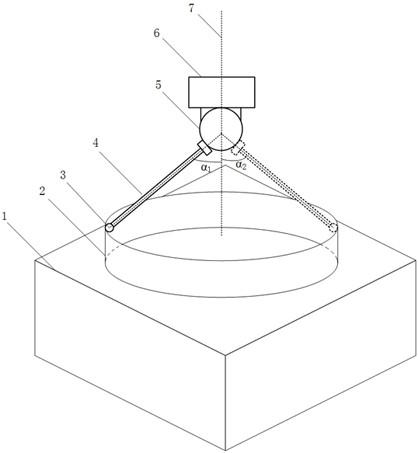

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] like figure 1 As shown, a method for calibrating the length of a REVO measuring head probe according to the present invention is used in a REVO five-axis measuring system under a non-orthogonal coordinate measuring machine. Granite slab, the specification is 1000×1000×150mm, the flatness of the working surface is 2.5μm; the ring gauge 2 is a special ring gauge for proofreading and smoothing, the tolerance is ±0.002mm, and the diameter range is 200mm-300mm; the specific steps are as follows:

[0026] S1. Fix the ring gauge 2 on the flat plate 1 placed horizontally, ensure that the ring gauge 2 does not move under the action of external force, make the A axis of the REVO probe at 0°, and move the main shaft of the measuring machine so that the center of the measuring ball 3 is in line with the The central axis of the ring gauge 2 coincides, and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com