Double-end seal dynamic running testbed and method

A running test and dynamic technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, by measuring the fluid's acceleration and deceleration rate, etc., can solve the problem of not being able to simulate mechanical seal operating conditions well, poor balance, and work efficiency. Low-level problems, to achieve the effect of effective inspection, strong versatility, and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

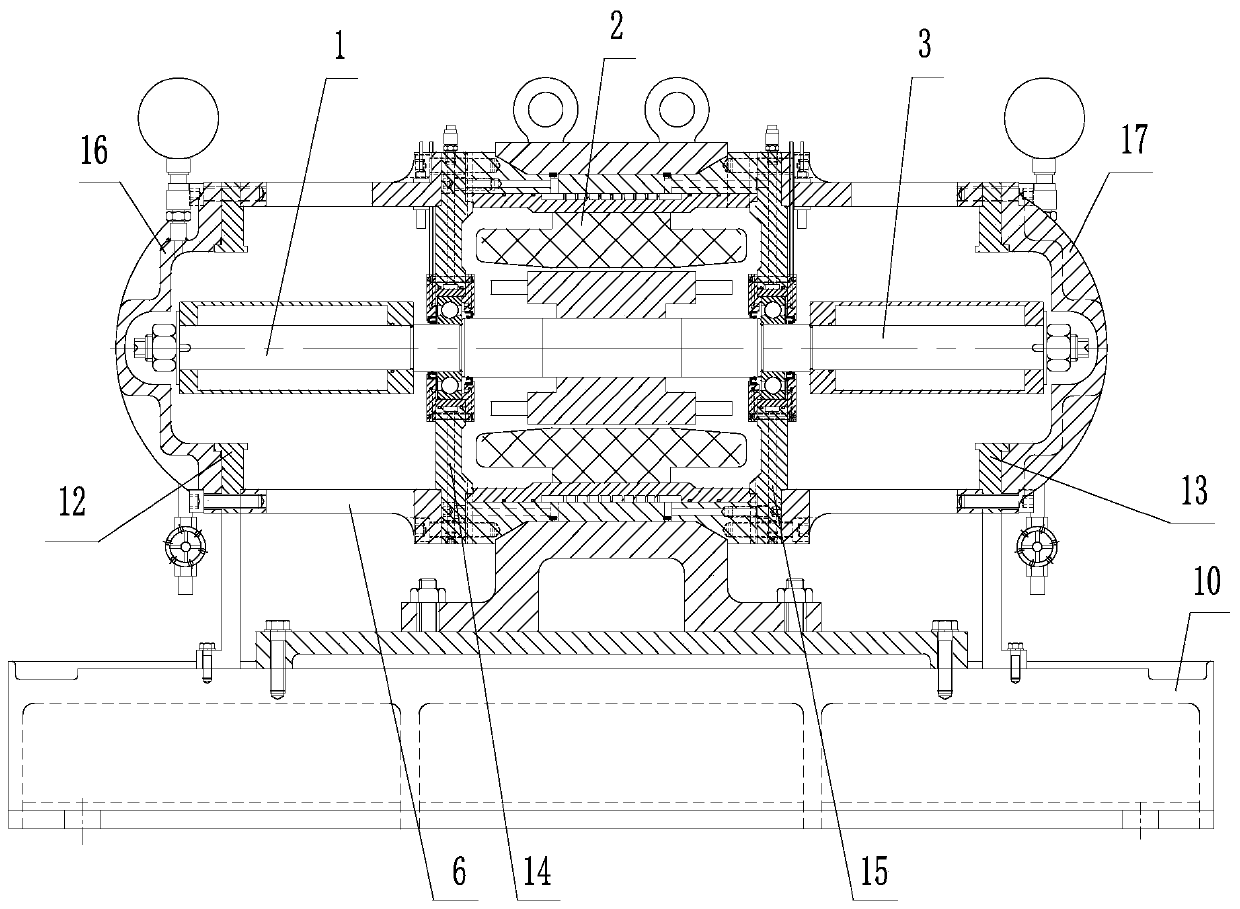

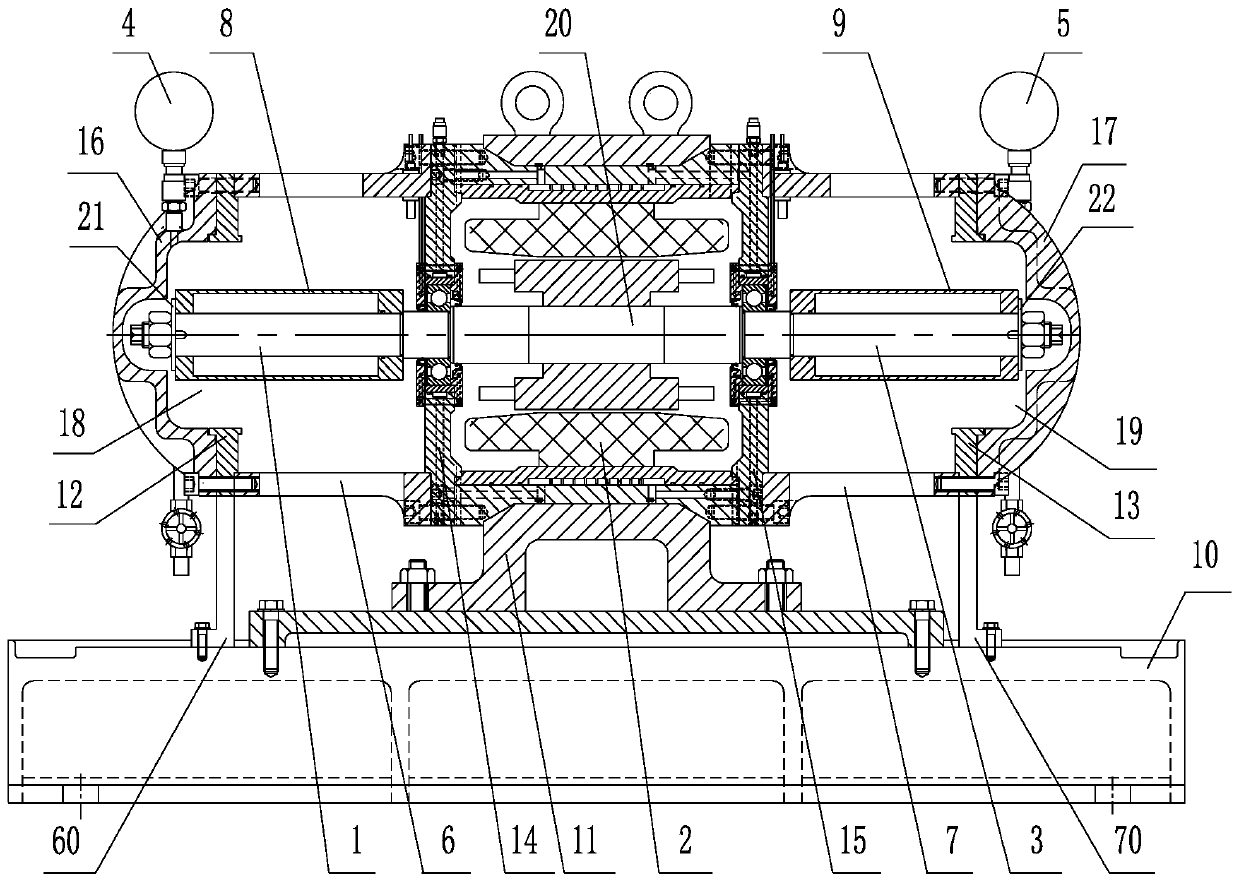

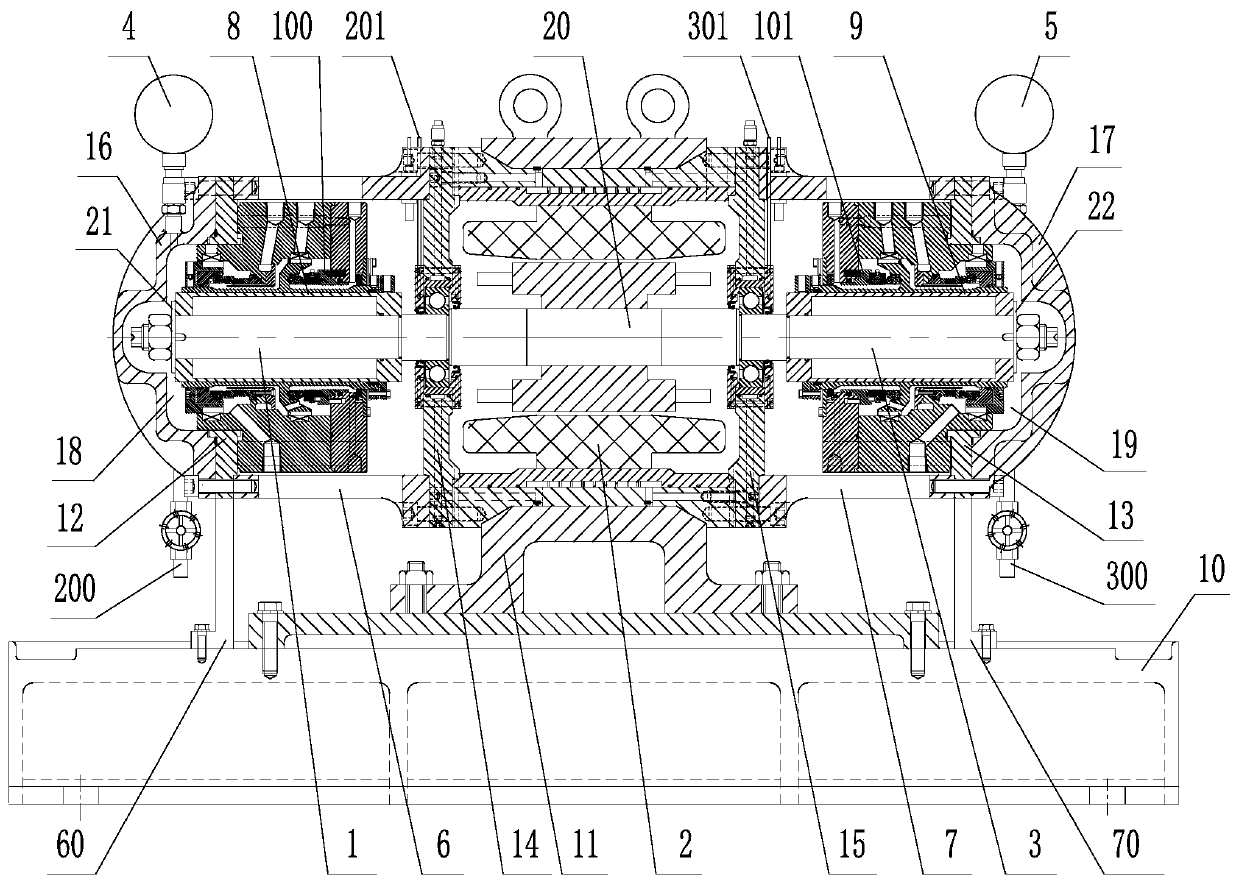

[0035] The following is attached figure 1 , figure 2 as well as image 3 The present invention is described in further detail.

[0036] Such as figure 1 and figure 2 As shown, a double-end seal dynamic operation test bench is composed of a first main shaft 1 , a motor 2 , a second main shaft 3 and a base 10 . The motor 2 is provided with a motor shaft 20, which is detachably connected to the motor 2, and the two ends of the motor shaft 20 are respectively connected to the first main shaft 1 and the second main shaft 3. The bottom of the motor 2 is provided with a motor bracket 11, the upper end of the motor bracket 11 is welded with the bottom of the motor 2, and the lower end of the motor bracket 11 is connected with the base 10 by bolts.

[0037] One end of the motor 2 is provided with a first inner flange 14, and one end of the first inner flange 14 is connected with one end of the motor 2 by bolts, and the other end of the first inner flange 14 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com