Camera optics, electronic equipment

A technology of optical mirrors and lenses, applied in optics, optical components, instruments, etc., can solve the problems of lens system enlargement, unfavorable device miniaturization, unsuitable optical systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The specific values of the conditional expression of the imaging optical mirror group of embodiment one are as follows:

[0079] |f1 / f|=7.93

[0080] |f2 / f|+|f3 / f|+|f4 / f|=3.72

[0081] AT1 / (AT1+AT2)=0.86

[0082] |R8 / R9|=2.58

[0083] |MSag8|=0.29

[0084] (V1+V4) / (V2+V3)=0.53

[0085] Then refer to Table 2 and Table 3 below.

[0086]

[0087]

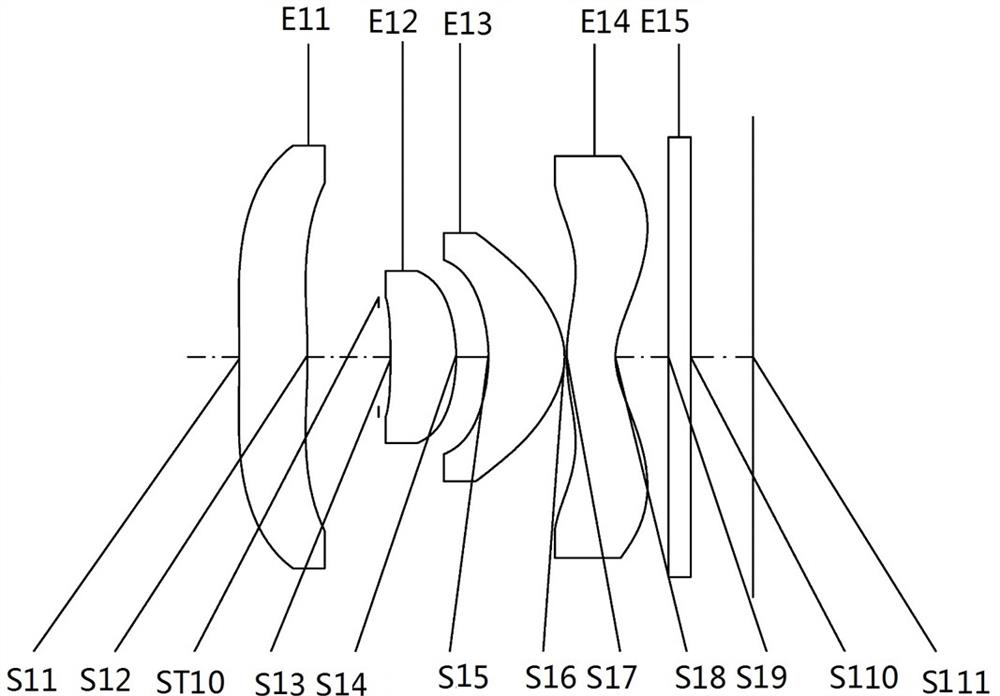

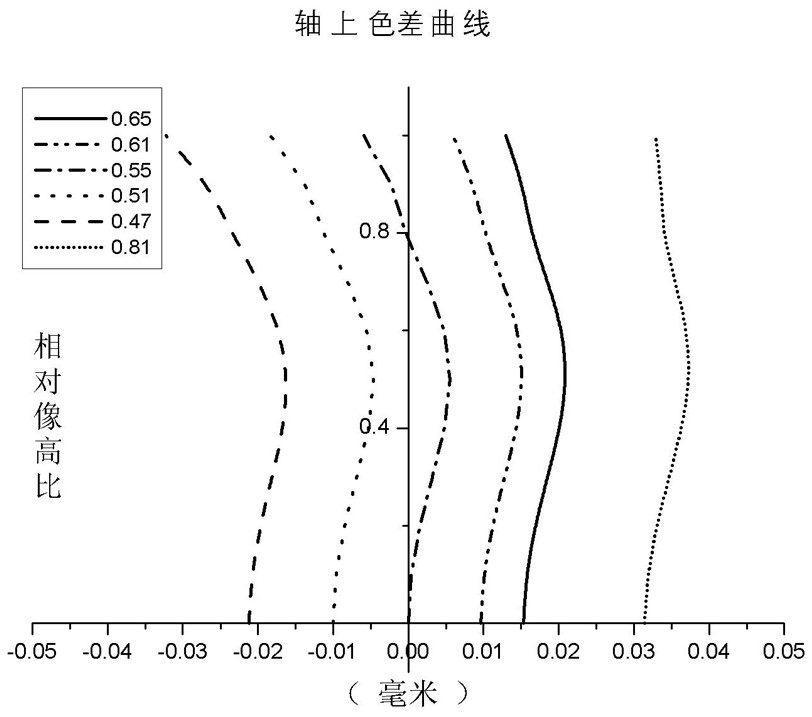

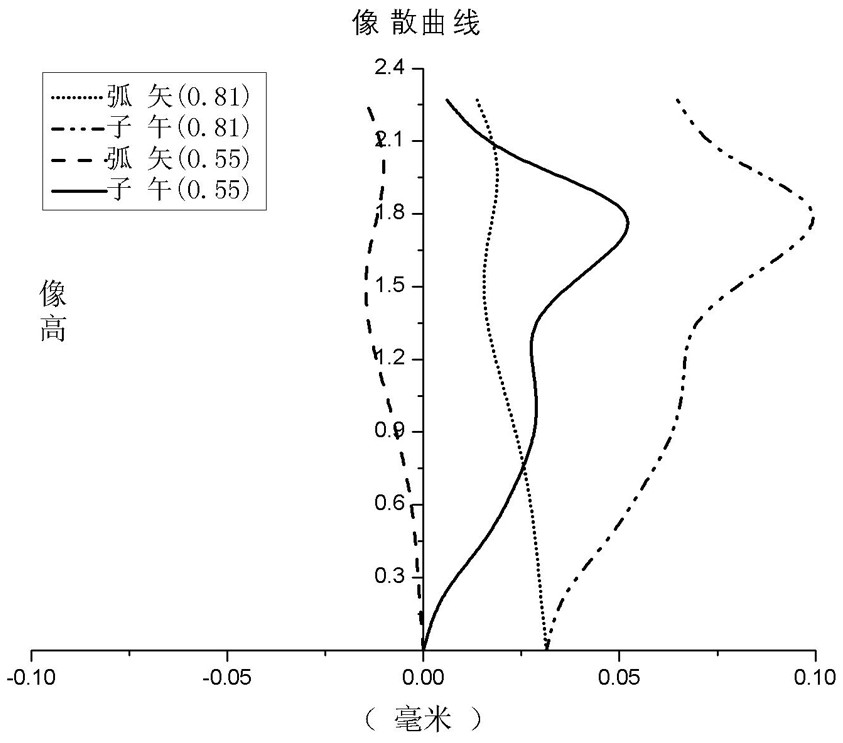

[0088]Table 2 shows the detailed structural data of Embodiment 1 in FIG. 1 , where the units of the radius of curvature, thickness and focal length are mm, and surfaces 0-12 represent surfaces from the object side to the image side in sequence. Table 3 shows the aspheric surface data in Example 1, wherein K represents the cone coefficient in the aspheric surface curve equation, and A4-A14 represent the 4th-16th order aspheric surface coefficients of each surface. In addition, the tables of the following embodiments correspond to the on-axis dispersion diagrams, astigmatism diagrams and distortion diagrams of the re...

Embodiment 2

[0090] The specific values of the conditional expression of the imaging optical mirror group of embodiment two are as follows:

[0091] |f1 / f|=8.58

[0092] |f2 / f|+|f3 / f|+|f4 / f|=3.75

[0093] AT1 / (AT1+AT2)=0.86

[0094] |R8 / R9|=2.69

[0095] |MSag8|=0.3

[0096] (V1+V4) / (V2+V3)=0.53

[0097] Then refer to Table 4 and Table 5 below.

[0098]

[0099]

Embodiment 3

[0101] The specific values of the conditional formula of the imaging optical mirror group of embodiment three are as follows:

[0102] |f1 / f|=8.36

[0103] |f2 / f|+|f3 / f|+|f4 / f|=3.72

[0104] AT1 / (AT1+AT2)=0.85

[0105] |R8 / R9|=2.66

[0106] |MSag8|=0.3

[0107] (V1+V4) / (V2+V3)=0.53

[0108] Then refer to Table 6 and Table 7 below.

[0109]

[0110]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com