Shaft sealing device and rotating electrical machine

A technology for rotating electrical machines and shaft seals, which is used in electromechanical devices, cooling/ventilation devices, mechanical equipment, etc., and can solve the problems of insufficient cooling gas sealing and low followability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

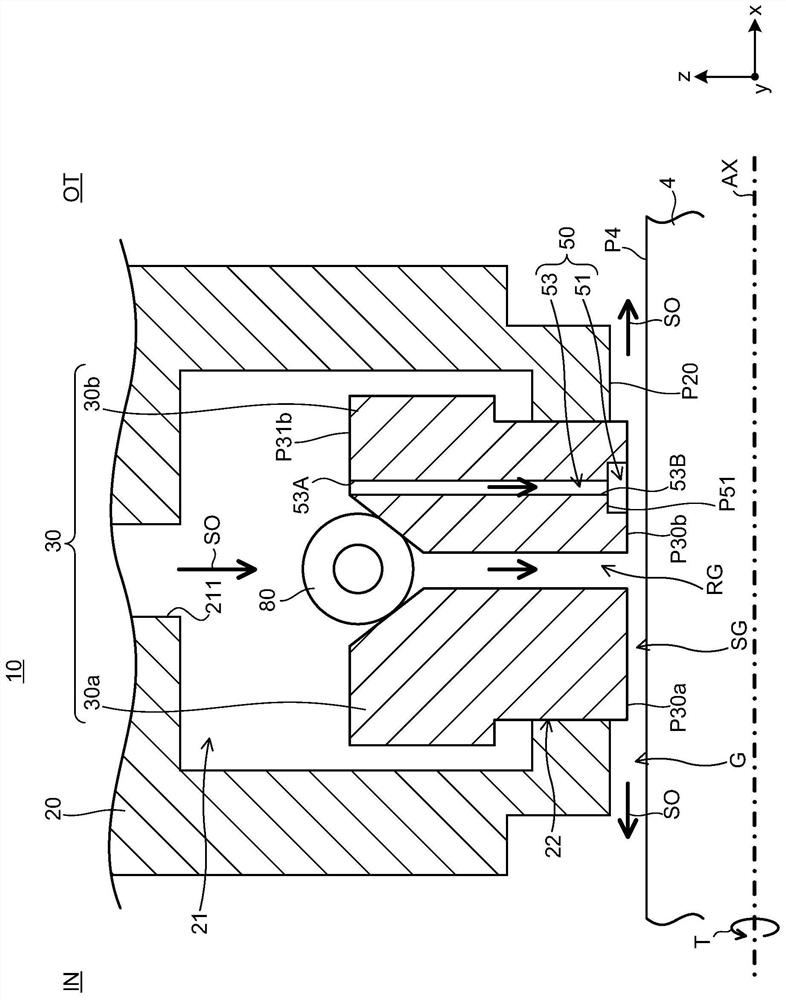

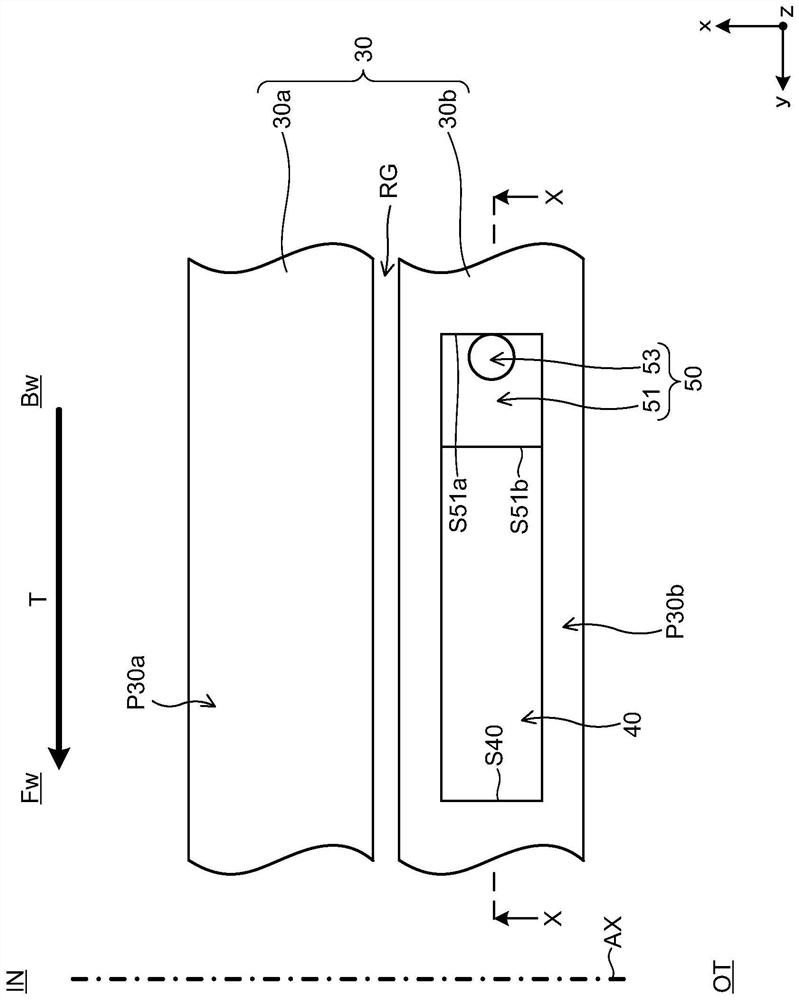

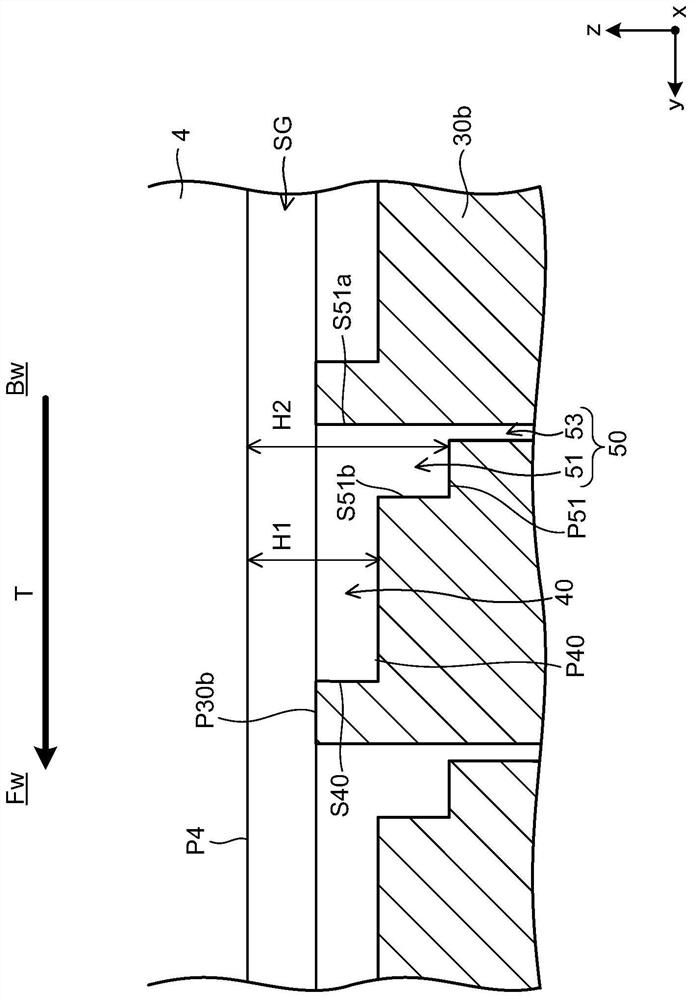

[0051] use figure 1 , figure 2 with image 3 The shaft seal device 10 according to the first embodiment will be described.

[0052] figure 1 and Figure 13 Similarly, a vertical plane (xz plane) cross section is shown for the shaft seal device 10 . figure 2 The inner peripheral surface of the seal ring 30 constituting the shaft sealing device 10 is shown. exist figure 2 Here, the longitudinal direction substantially corresponds to the axial direction (x) along the rotation center axis AX, and the upper side is the body inner side IN, and the lower side is the body outer side OT. and, figure 2 The middle lateral direction substantially corresponds to the rotation direction T, and the left side is the front side Fw of the rotation direction T, and the right side is the rear side Bw. image 3 For the shaft seal device 10, the figure 2 The cross-section of the XX-X part. image 3 Among them, the longitudinal direction substantially corresponds to the radial direct...

no. 2 Embodiment approach >

[0082] use Figure 7 The shaft seal device 10 according to the second embodiment will be described. Figure 7 neutralize figure 2 Similarly, the inner peripheral surface of the seal ring 30 constituting the shaft seal device 10 is shown.

[0083] Such as Figure 7 As shown, part of the form of the inner peripheral surface P30b of the body-external side gasket member 30b in the gasket 30 of this embodiment is similar to that of the first embodiment (see figure 2 )different. Except for this point and related points, this embodiment is the same as that of the first embodiment, and thus description thereof will be appropriately omitted.

[0084]In this embodiment, an oil discharge groove 45 is formed on the inner peripheral surface P30b of the body outer packing member 30b. The oil discharge groove 45 communicates with the groove 40 on the front side Fw of the groove 40 in the rotational direction T. As shown in FIG. The oil discharge groove 45 is configured to discharge t...

no. 3 Embodiment approach >

[0093] use Figure 9 with Figure 10 The shaft seal device 10 according to the third embodiment will be described. Figure 9 neutralize figure 1 Likewise, the shaft seal device 10 shows a cross section on a vertical plane (xz plane). Figure 10 neutralize figure 2 Similarly, the inner peripheral surface of the seal ring 30 constituting the shaft seal device 10 is shown.

[0094] Such as Figure 9 with Figure 10 As shown, part of the form of the inner peripheral surface P30b of the body-external side gasket member 30b in the gasket 30 of this embodiment is similar to that of the first embodiment (see figure 1 with figure 2 )different. Except for this point and related points, this embodiment is the same as that of the first embodiment, and thus description thereof will be appropriately omitted.

[0095] In the present embodiment, the oil discharge port 46 is formed in a portion of the inner peripheral surface P30b of the body-outside gasket member 30b that is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com