Sizing and straightening process of welded steel pipe

A welded steel pipe and sizing technology, which is applied in the field of welded steel pipe sizing and straightening technology, can solve the problems of no stiffness, inability to reduce diameter, and non-adjustable steel pipe size, etc., and achieve the effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Take the sizing and straightening process of the 245 welded pipe production line as an example. The production specification range of 245 welded pipe production line is Φ100-245mm in outer diameter and 6-16mm in wall thickness. The product varieties are high-strength steel welded pipes and line pipes, etc., and the yield strength of the materials is 345-650MPa.

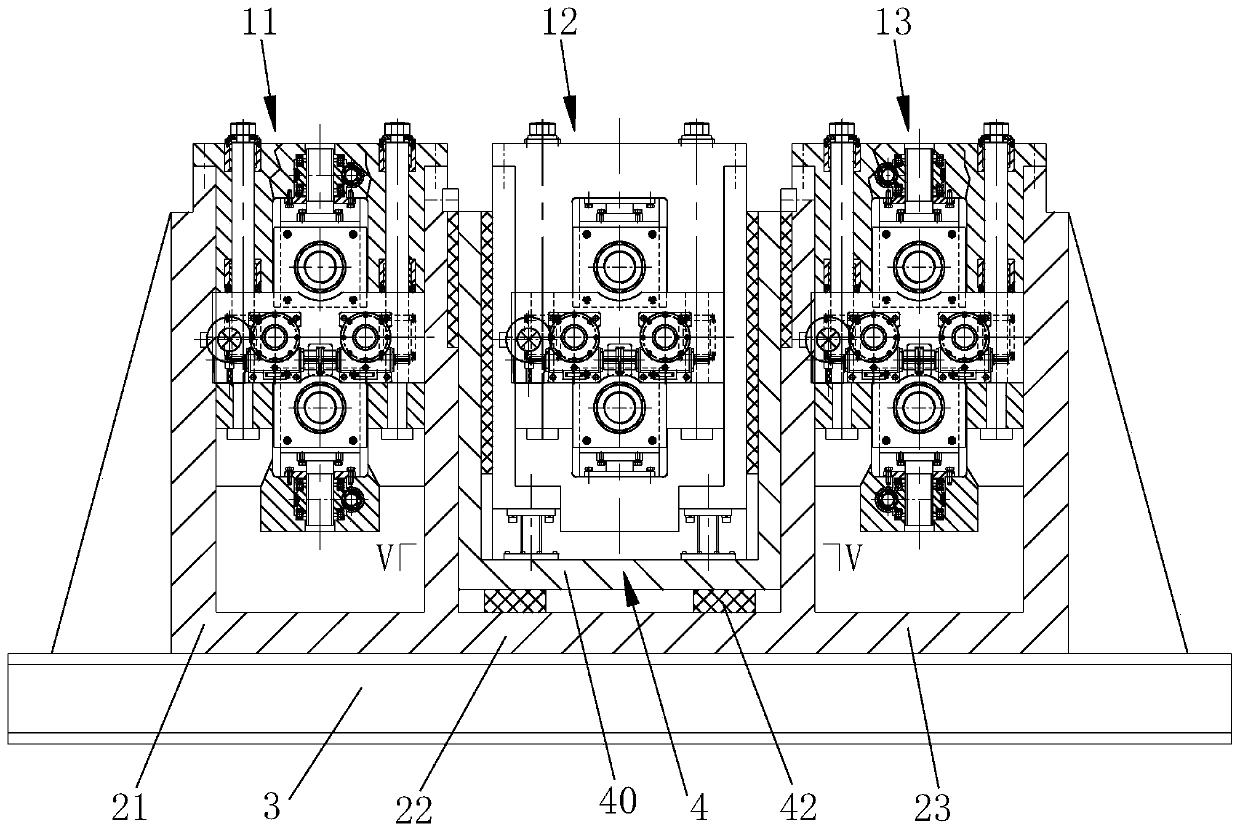

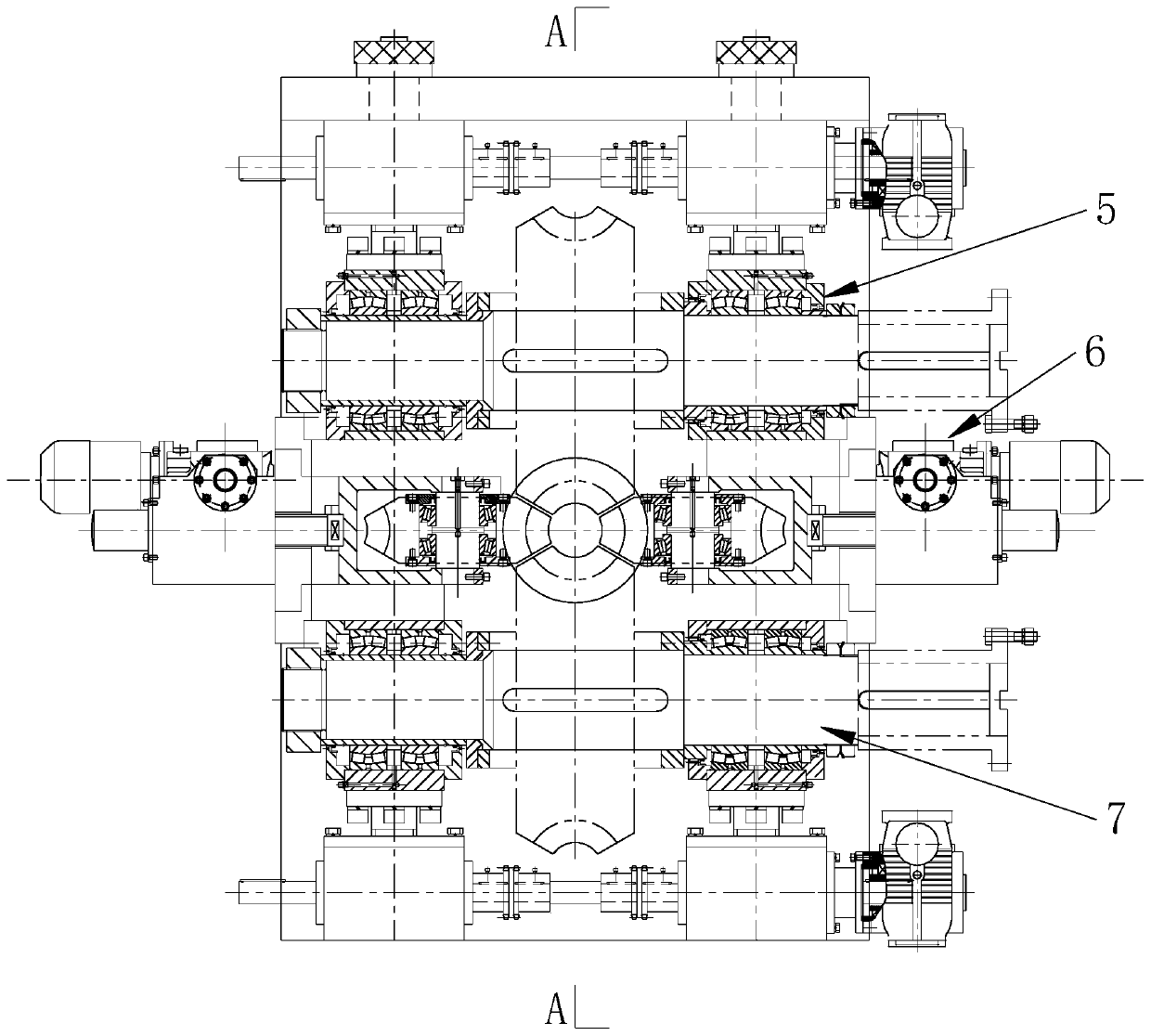

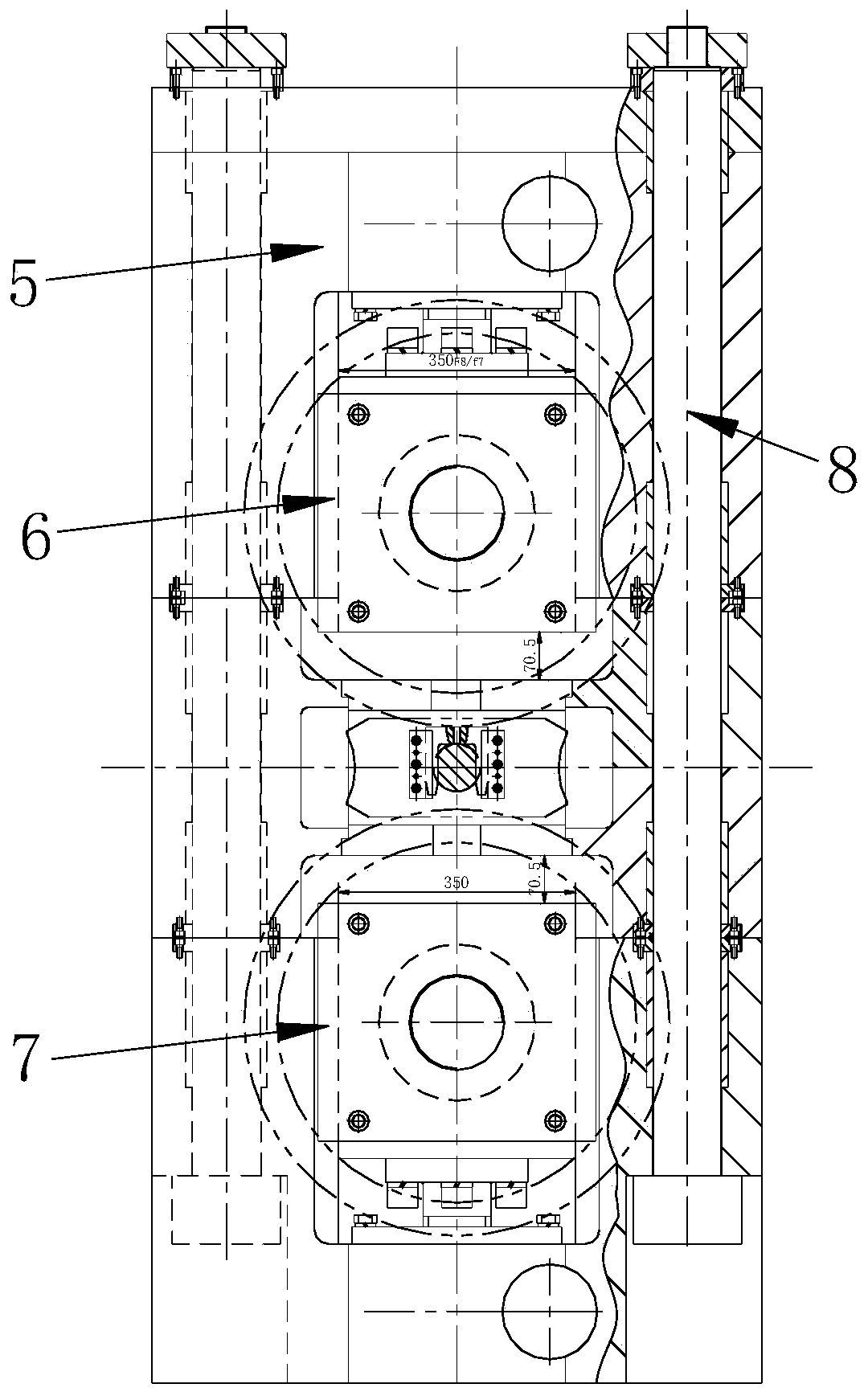

[0035] Firstly, the sizing and straightening device will be described below, please refer to Figure 1-Figure 3 , the sizing and straightening device includes an integral sizing base 3, on which three rack mounts are successively installed, and these three rack mounts are respectively the first rack mount 21, the second rack mount in order. Frame mounting seat 22 and the 3rd frame mounting seat 23, the first four-roller assembly 11 is installed in the first frame mounting seat 21, the second four-roller assembly 11 is installed in the second frame mounting seat 22 Assembly 12, the third four-roller assembly 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap