Centralizer

A centralizer and consistent technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of insufficient reset force of centralizer, easy permanent deformation of working rib, insufficient centering of wellbore, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

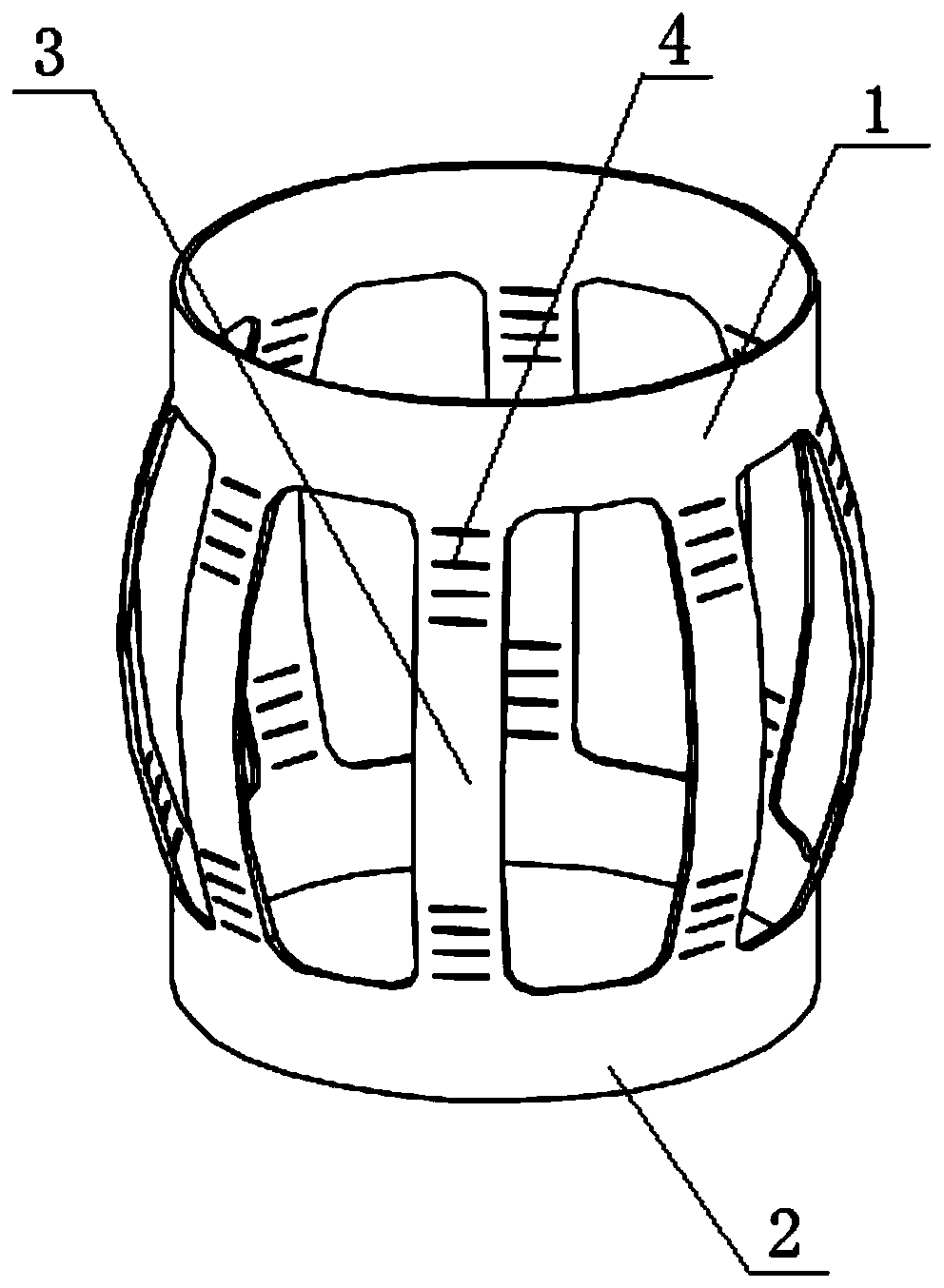

[0027] Such as figure 1 As shown, the centralizer of the present invention includes an upper end ring 1 and a lower end ring 2 with the same diameter; several working ribs 3 are fixedly connected between the upper end ring 1 and the lower end ring 2; the working ribs 3 surround the upper end ring 1 or the lower end ring The circumference of 2 is evenly distributed; the width of the working rib 3 is between 30-130 mm; and several stress relief grooves 4 are also included. The stress relief groove 4 is opened on the working rib 3 . The shape of the stress relief groove 4 is a horizontal straight line, a vertical straight line or an arc shape. The arc-shaped stress relief groove 4 located at the lower part of the working rib 3 is arranged in a herringbone shape. The radius range of the arc-shaped stress relief groove 4 is R20-80mm. The distance between the stress relief groove 4 and the edge of the working rib 3 on the same side is 10-20 mm. The length of a single stress reli...

Embodiment 2

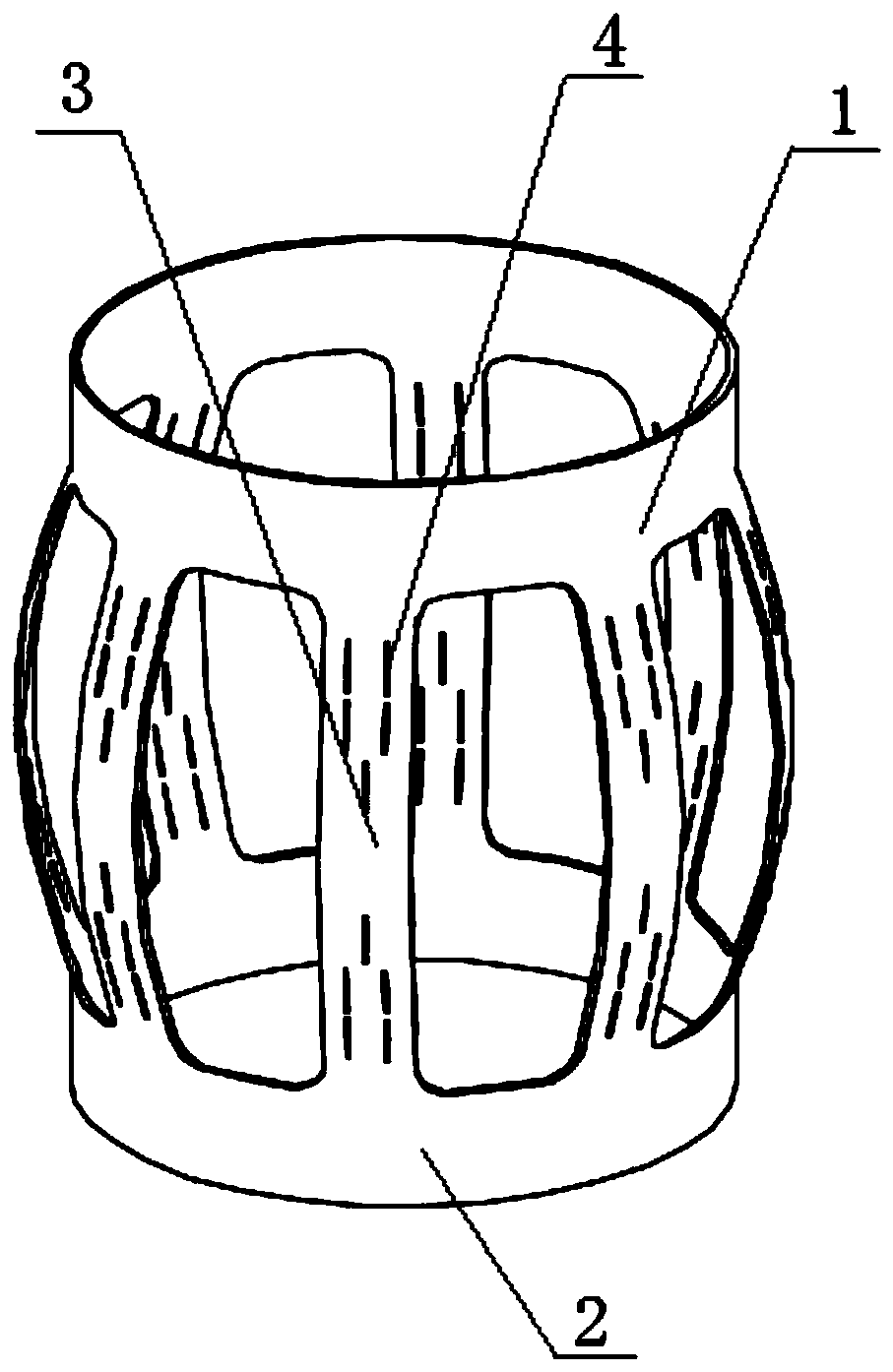

[0030] Such as figure 2 As shown, it is roughly the same as Embodiment 1, the only difference is that the shape of the stress relief groove 4 is a longitudinal linear shape; the stress relief groove 4 located at the lower part of the working rib 3 has several rows, the first row is one, and is located at the working rib 3. The longitudinal symmetry axis of the rib 3; below the second row, each row has two, and the two stress relief grooves 4 are symmetrically distributed, and the symmetry axis is collinear with the longitudinal symmetry axis of the working rib 3; two adjacent rows of stress relief grooves The longitudinal distance between 4 is consistent, which is 10-40mm; below the second row, the transverse distance between the two stress-relief grooves 4 in each row is 20-100mm.

Embodiment 3

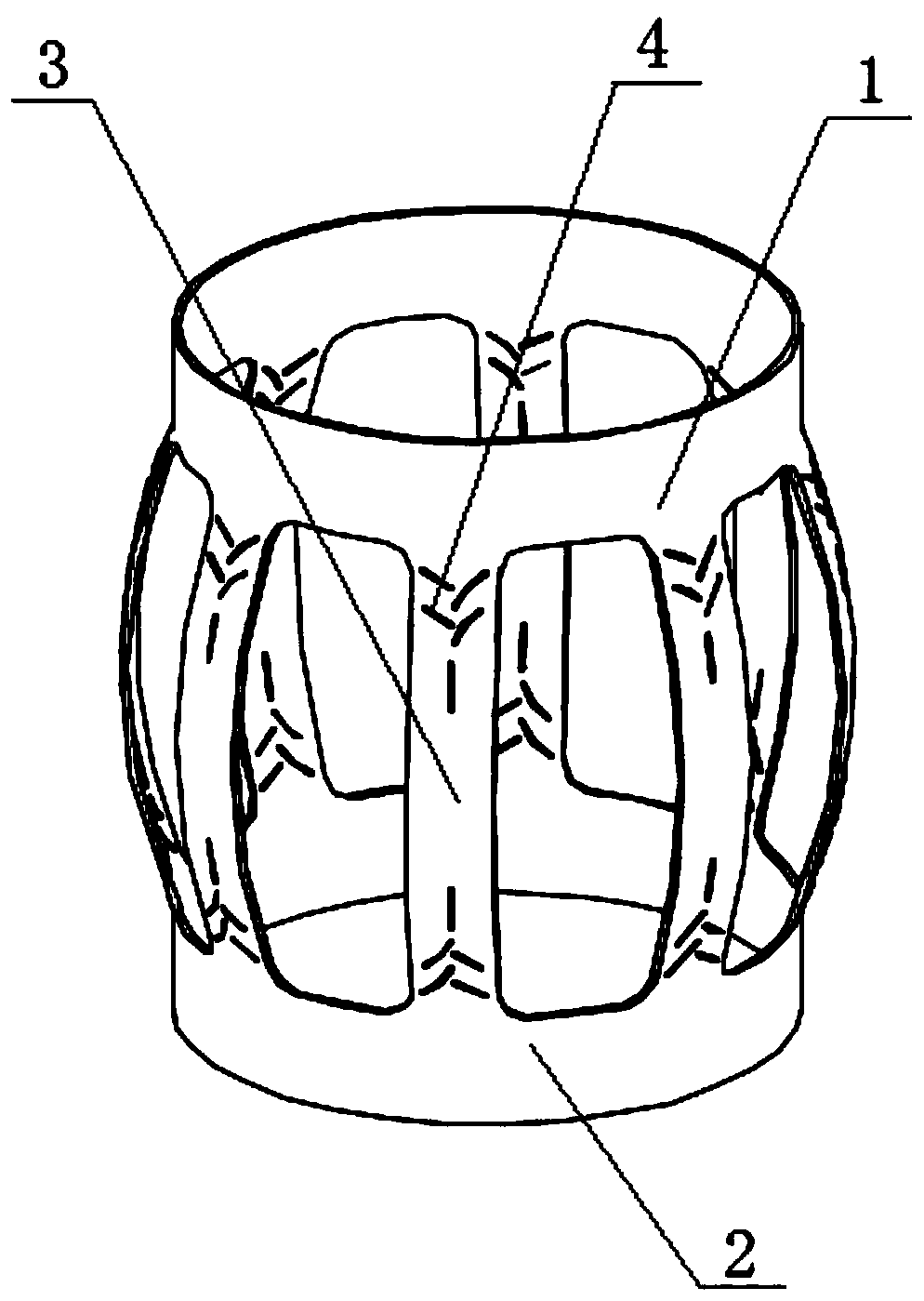

[0032] Such as image 3 As shown, it is roughly the same as that of Embodiment 1, the only difference is: specifically, there are several rows of stress relief grooves 4 located at the bottom of the working rib plate 3, and the first row is a longitudinal linear stress relief groove 4, which is located at the working rib The longitudinal axis of symmetry of the plate 3; below the second row, there are two in each row, and the two stress relief grooves 4 are distributed in a herringbone shape; the longitudinal distance between two adjacent rows of stress relief grooves 4 is at least 10 mm, and the maximum 40mm; below the second row, the lateral distance between the two stress relief grooves 4 in each row is at least 5mm and at most 30mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com